Modular and Compact Valve Terminals for Smart Automation Systems — NTA

Key Features of NTA Valve Terminals

Compact and Space-Saving: Multiple valves combined in one unit minimize wiring and tubing complexity.

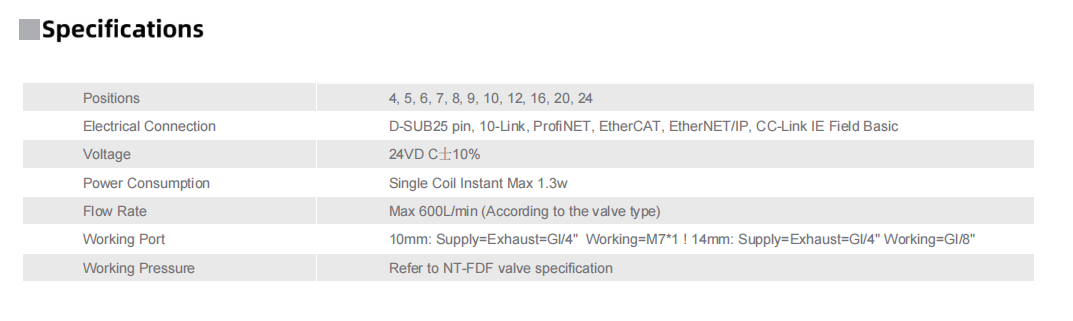

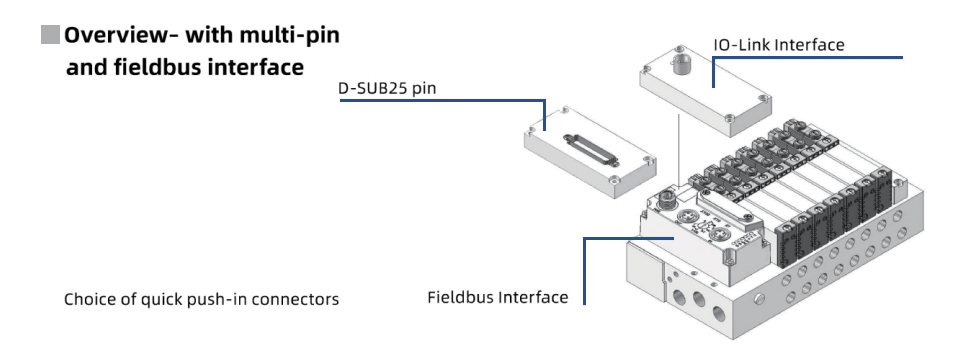

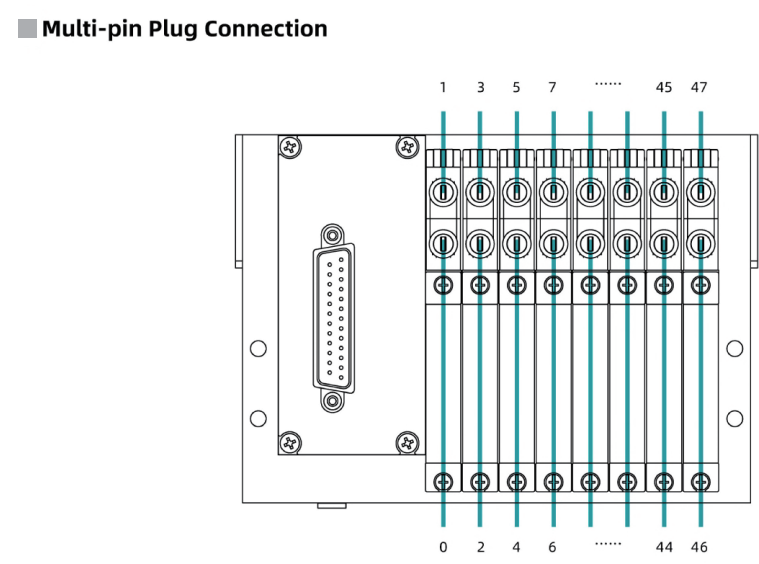

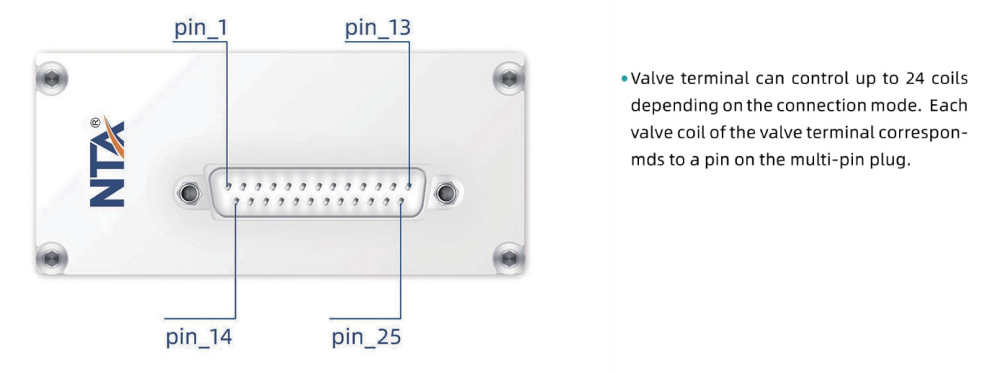

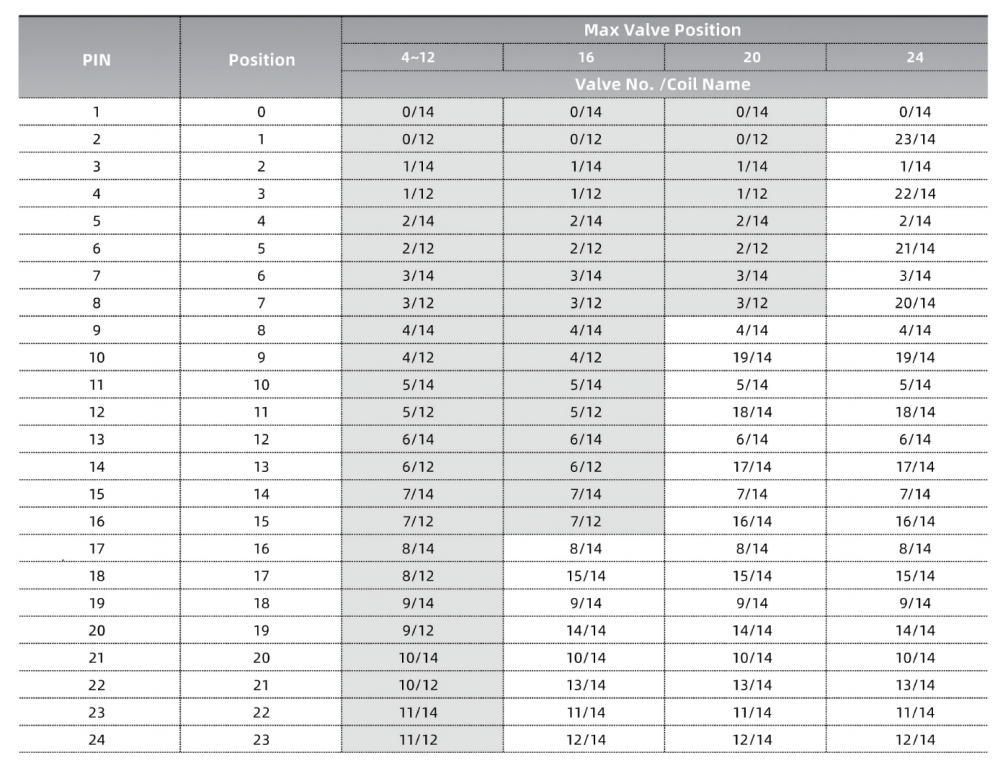

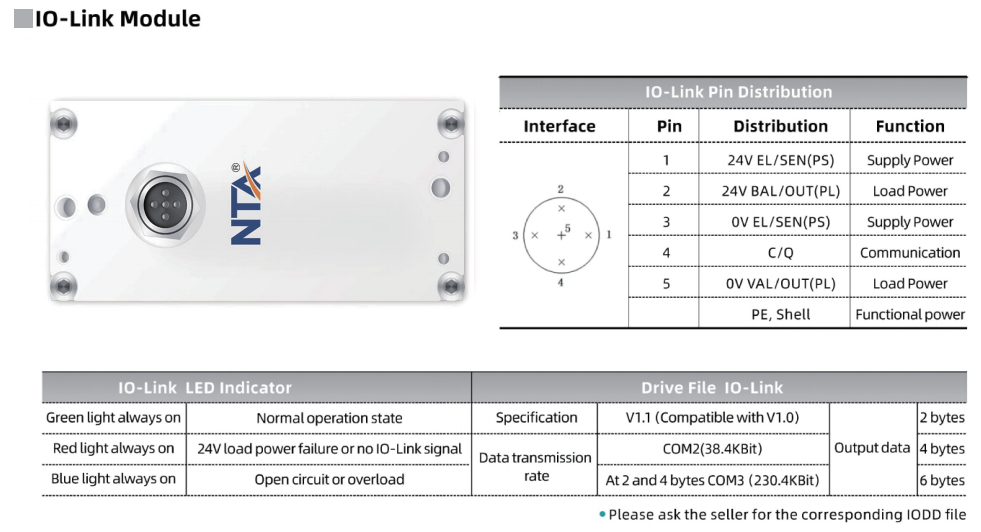

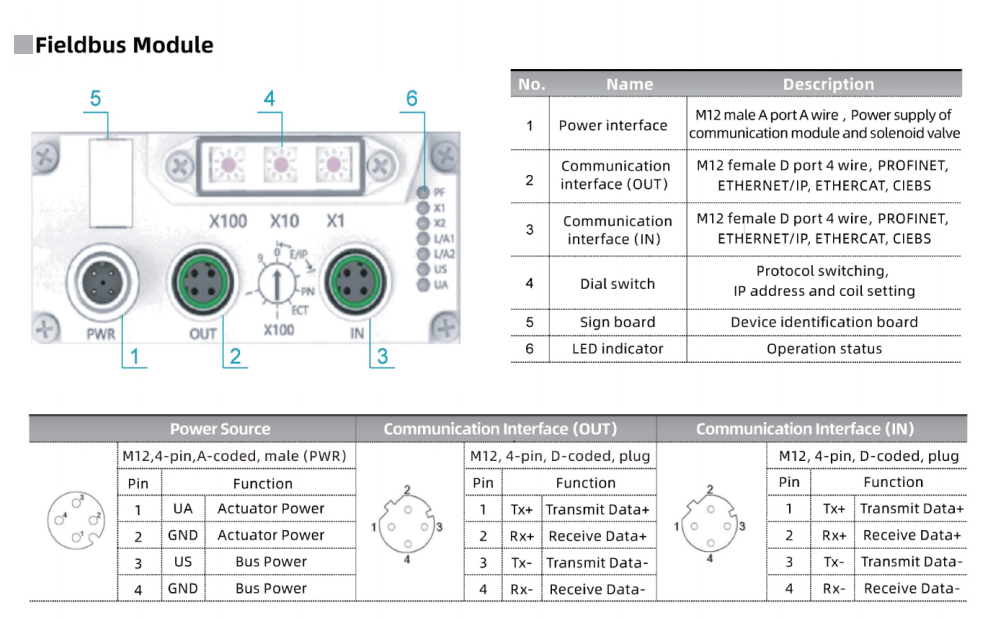

Flexible Interfaces: Support for 25-pin connection, IO-Link modules, and Fieldbus protocols ensures seamless integration with various control architectures.

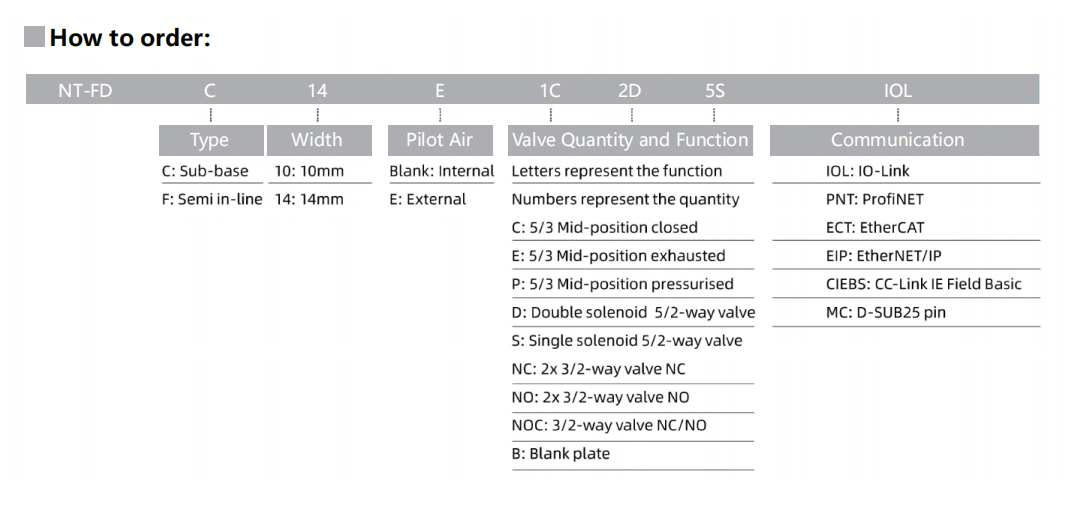

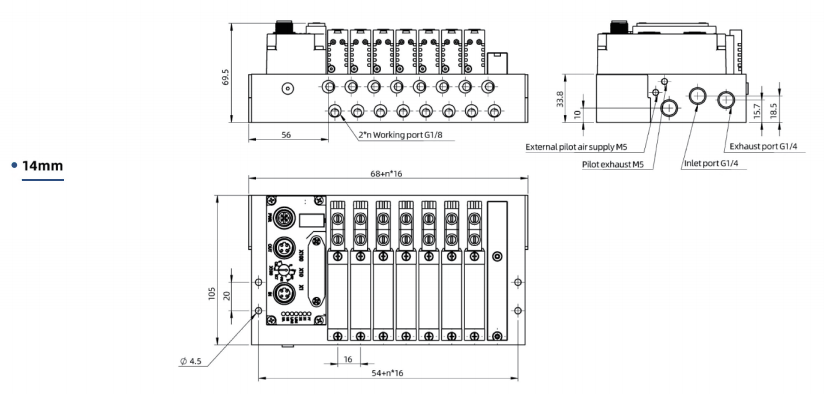

Customizable Options: Available in 10mm and 14mm solenoid valve sizes, meeting both low-flow and high-flow requirements.

High Reliability: Built with ISO-grade materials, ensuring long service life and consistent operation in demanding environments.

Easy Maintenance: Modular construction allows quick replacement and expansion without major downtime.

NTA valve terminals offer 25-pin, IO-Link, and Fieldbus interfaces, ensuring easy wiring, intelligent data exchange, and reliable communication for flexible integration in modern automation systems.

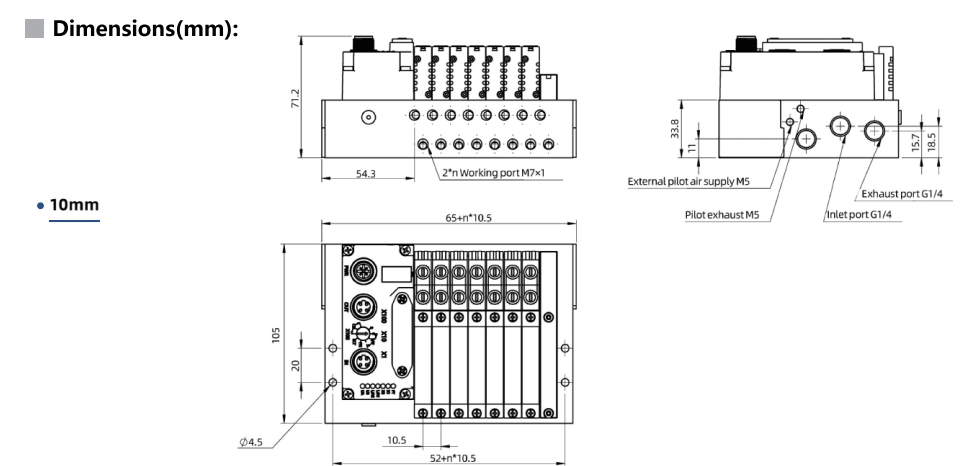

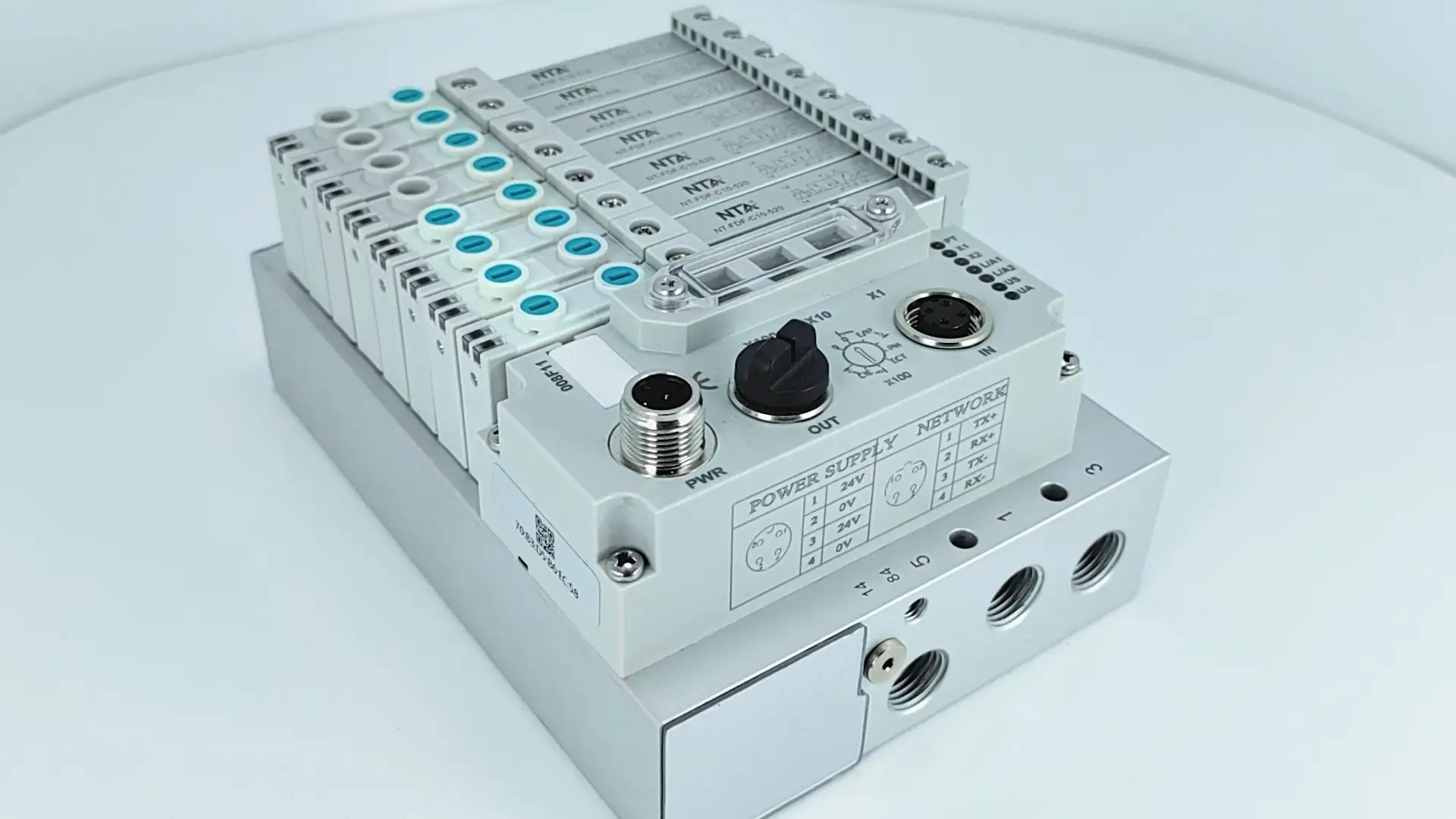

NTA valve terminals integrate 10mm solenoid valves in a slim design that delivers strong airflow capacity. Their compact structure is well-suited for tight layouts, ensuring quick actuation and dependable performance in continuous automation processes.

NTA valve terminals incorporate 14mm solenoid valves designed for greater airflow and durability. Their larger capacity makes them ideal for demanding pneumatic tasks, ensuring consistent switching, reliable control, and long-term efficiency in automation environments.

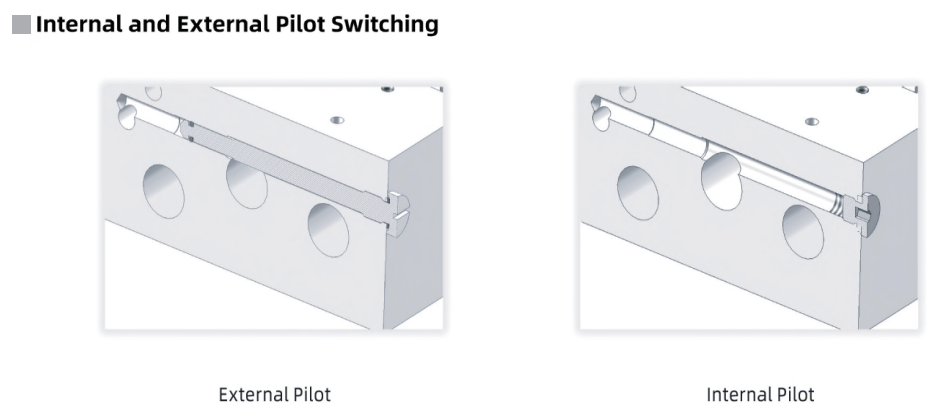

When a screw is mounted in the pilot port, the valve operates with an external pilot, supplied through the M5 thread on the base plate. By fitting an M5 plug instead, the unit switches to internal pilot mode, drawing control air directly from the main inlet.

NTA valve terminals equipped with IO-Link technology provide continuous status feedback, easy parameter adjustment, and enhanced fault detection. Using standard cabling, they streamline installation and enable predictive maintenance, supporting greater efficiency and uptime in automated production.

Application Scenarios

NTA valve terminals are widely used in:

Packaging and Filling Lines – coordinating synchronized pneumatic control.

Robotics and Handling Systems – supporting precise and fast actuation.

Assembly Automation – enabling centralized and efficient air distribution.

Conveyors and Process Equipment – reducing system footprint and improving throughput.

These advantages make them an ideal valve terminal for industrial automation, especially in high-speed production lines where stability and efficiency are critical.

Boosting Productivity

By consolidating multiple pneumatic functions, NTA valve terminals reduce installation time, lower maintenance costs, and improve production stability. Advanced diagnostic capabilities through IO-Link further enable predictive maintenance, reducing unexpected downtime. With reliable pneumatic valve terminal solutions, manufacturers can achieve better output and long-term performance.

Why Choose NTA?

Proven expertise as an industrial valve terminal manufacturer

Strong export capability with stable global logistics

ISO-certified quality control for consistent reliability

Full technical support from design to after-sales service

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.