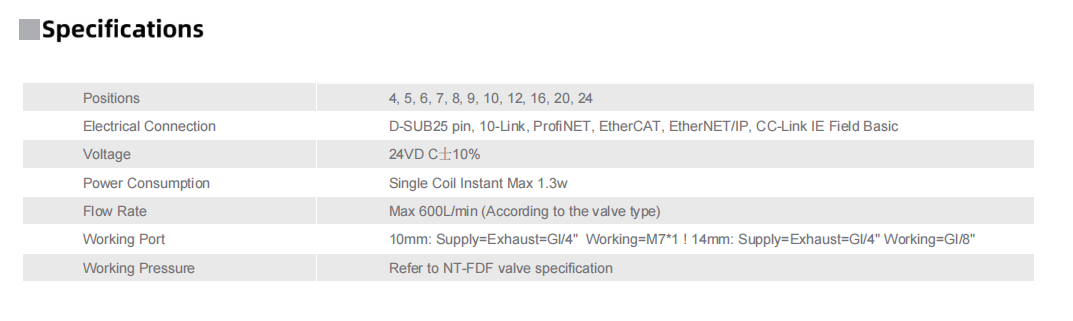

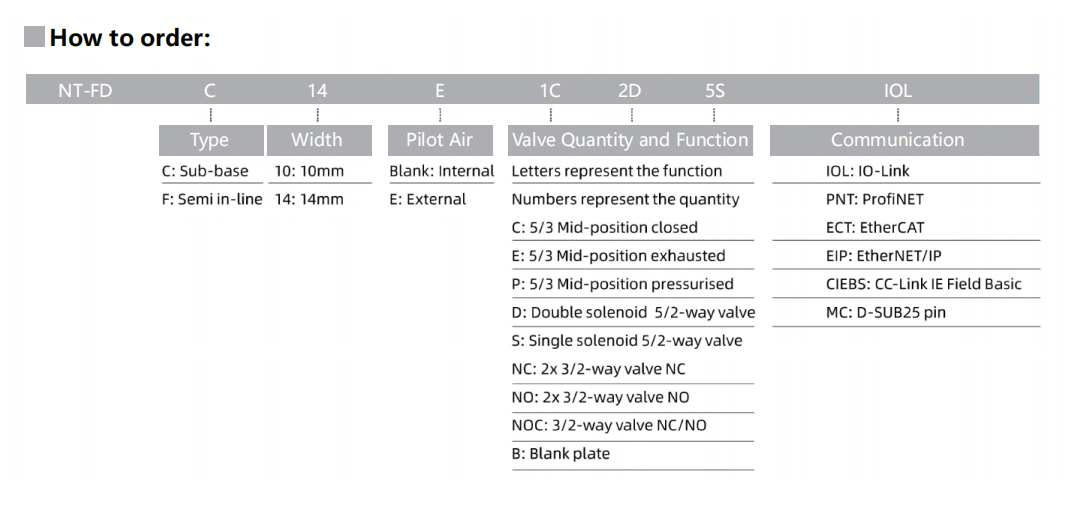

Titan Automation Valve Terminal NTA011Series - Modular Valve Terminal System

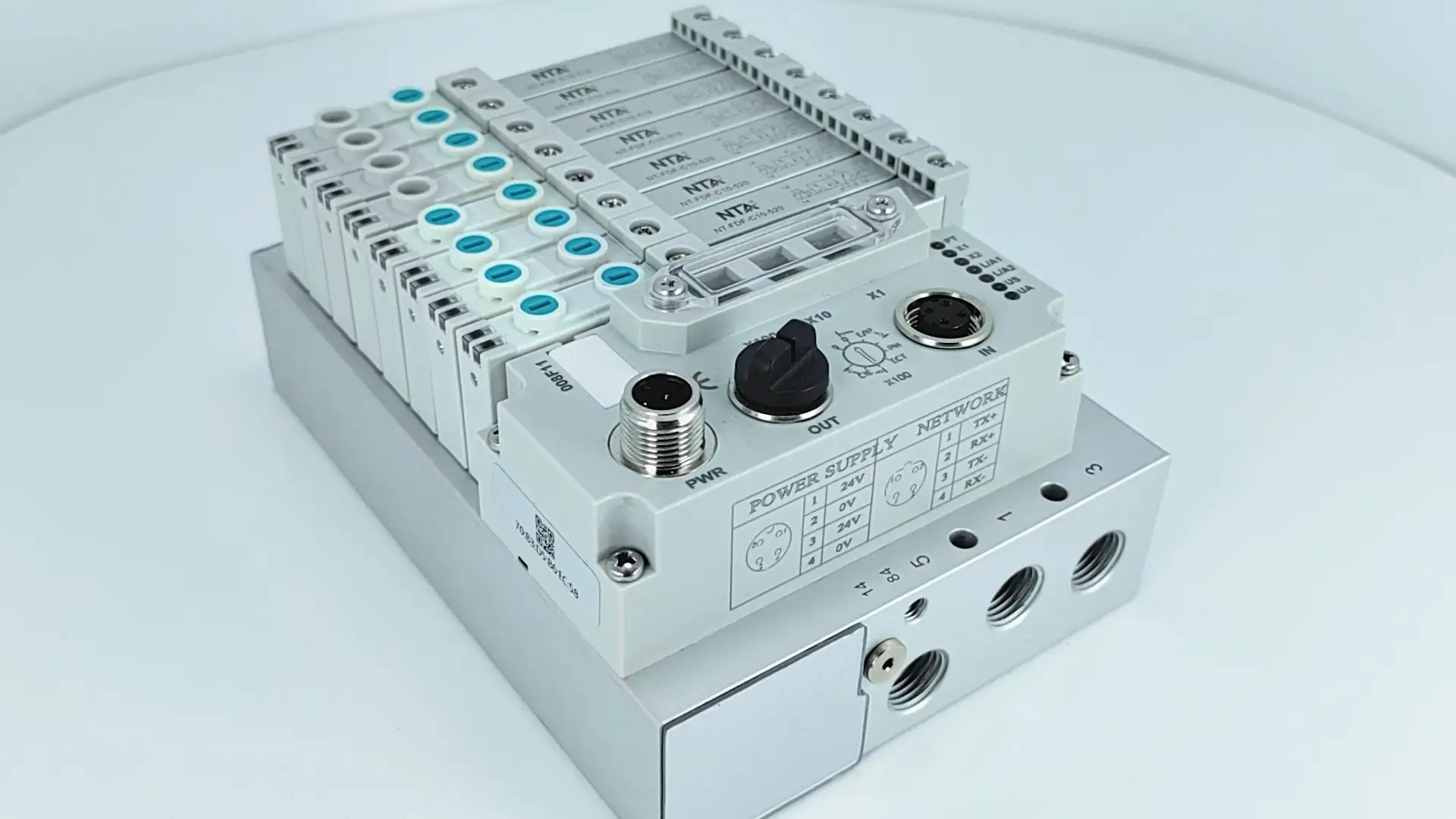

NTA valve terminals represent the perfect combination of compact design, intelligent control, and proven quality. Designed for evolving automation needs, they help industries achieve higher production efficiency, system flexibility, and long-term operational stability.

Whether in smart factories, robotic systems, or automated assembly lines, NTA provides innovative solutions that drive the future of pneumatic automation.

Product Overview

NTA valve terminals integrate multiple solenoid valves into a single modular unit, enabling centralized pneumatic control. This design minimizes tubing, wiring, and installation space — ensuring cleaner layouts and easier maintenance. Built using high-quality aluminum and wear-resistant sealing materials, they provide stable air flow and long-lasting performance, even under demanding industrial conditions.

With their high response speed and efficient air management, NTA terminals are the ideal solution for high-precision pneumatic control valve assemblies used in intelligent manufacturing and robotic automation.

Product Features

Modular configuration supports multiple valve sizes and flow capacities

Fast and precise response ensures accurate actuation in real-time processes

Streamlined air paths minimize energy loss and enhance air efficiency

Multiple interface options for flexible system integration

Compact structure reduces footprint and simplifies machine layout

These features make NTA products a key part of automated pneumatic manifold valve control systems for industries seeking higher speed and reliability.

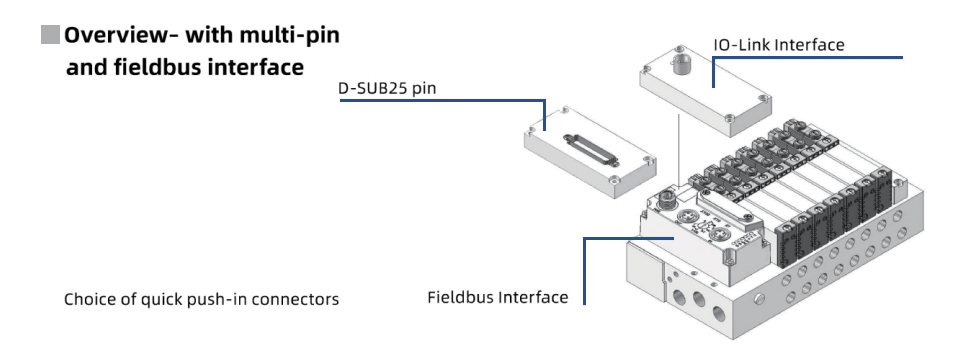

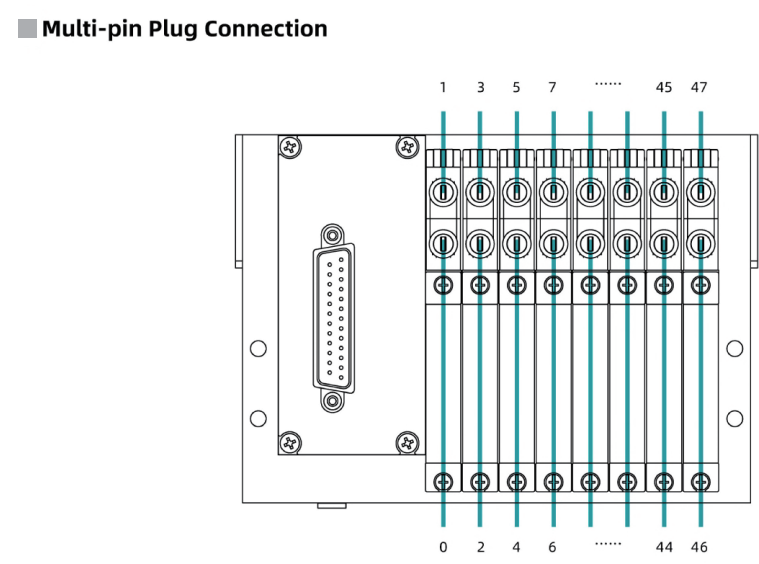

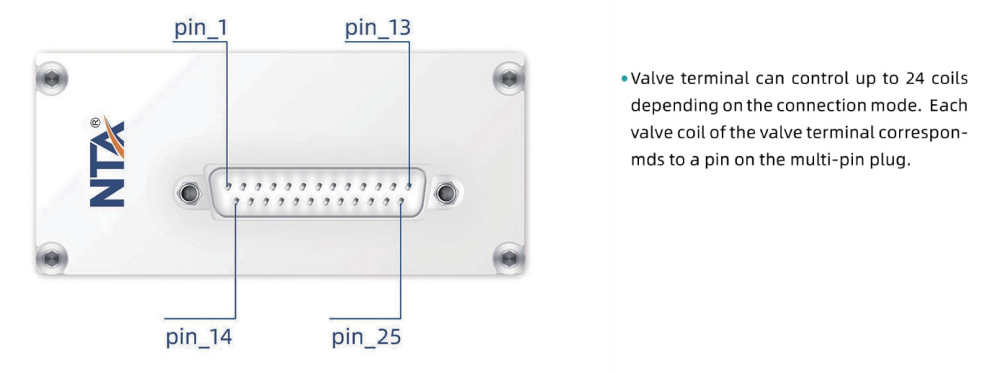

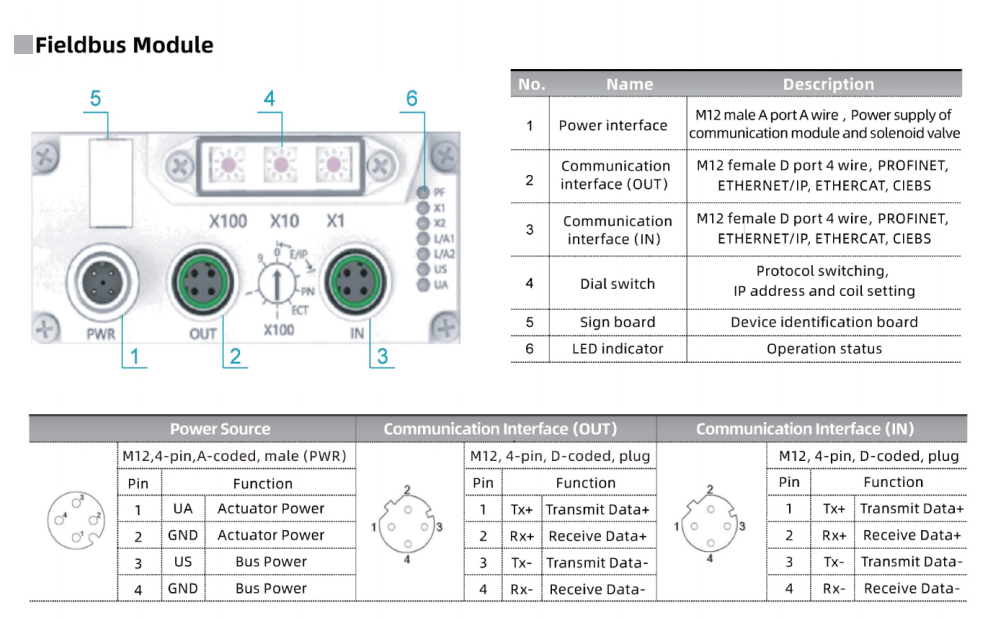

NTA valve terminals offer versatile interface options including 25-pin, IO-Link, and Fieldbus connections, allowing seamless integration, stable data transmission, and enhanced efficiency across various automation systems.

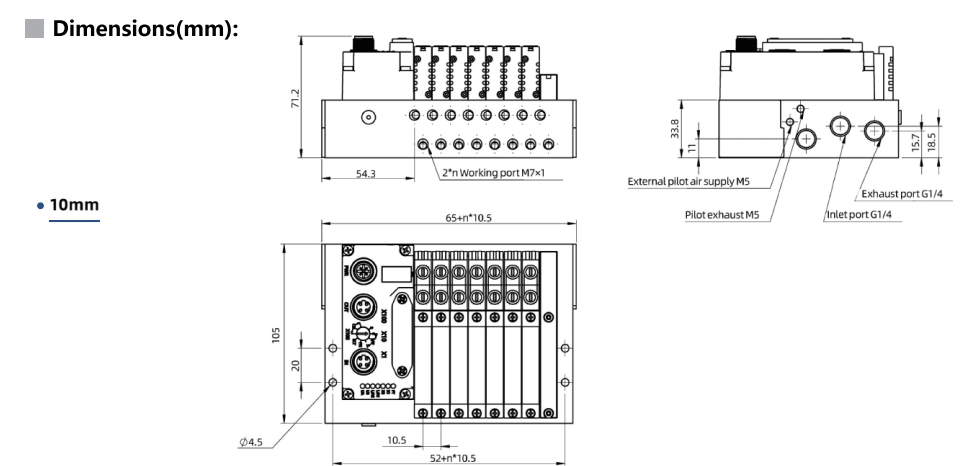

NTA valve terminals integrate 10 mm solenoid valves within a highly compact structure, achieving excellent flow efficiency while minimizing mounting space. The optimized configuration ensures fast response and stable operation under demanding industrial automation conditions.

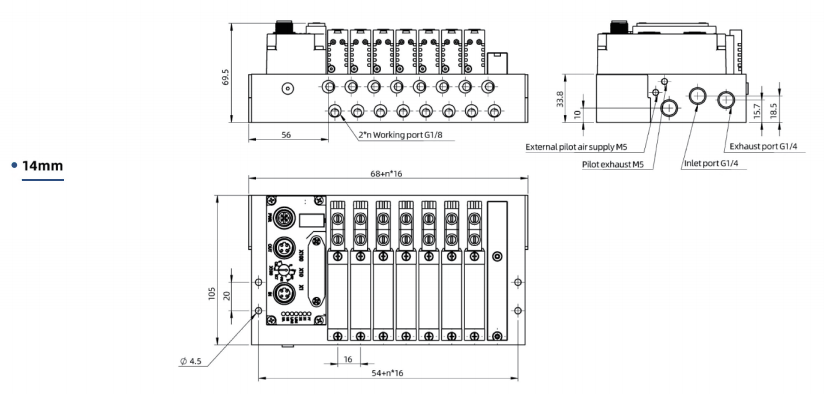

NTA valve terminals feature 14 mm solenoid valves optimized for high flow delivery and stable actuation. Purpose-built for demanding automation environments, they ensure accurate control, exceptional durability, and energy-efficient performance across advanced production operations.

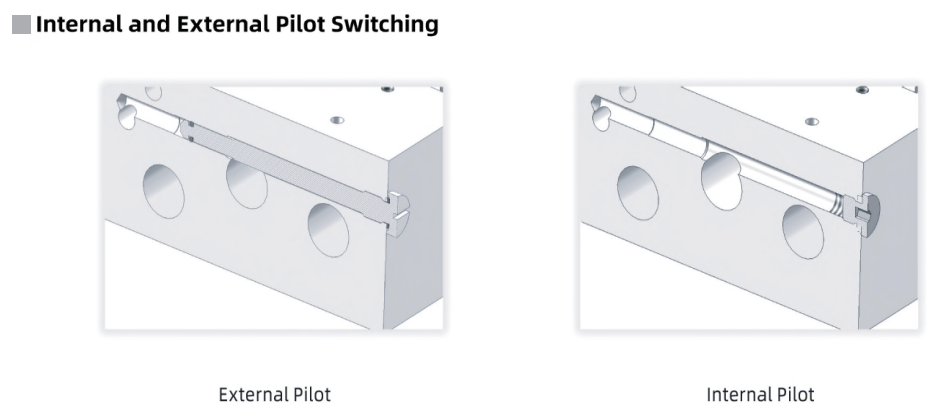

Fitting a screw into the pilot port enables external pilot operation, allowing pilot air to flow through the M5 threaded port on the base plate. When an M5 plug is installed instead, the valve operates in internal pilot mode, utilizing pilot air supplied directly from the main air inlet.

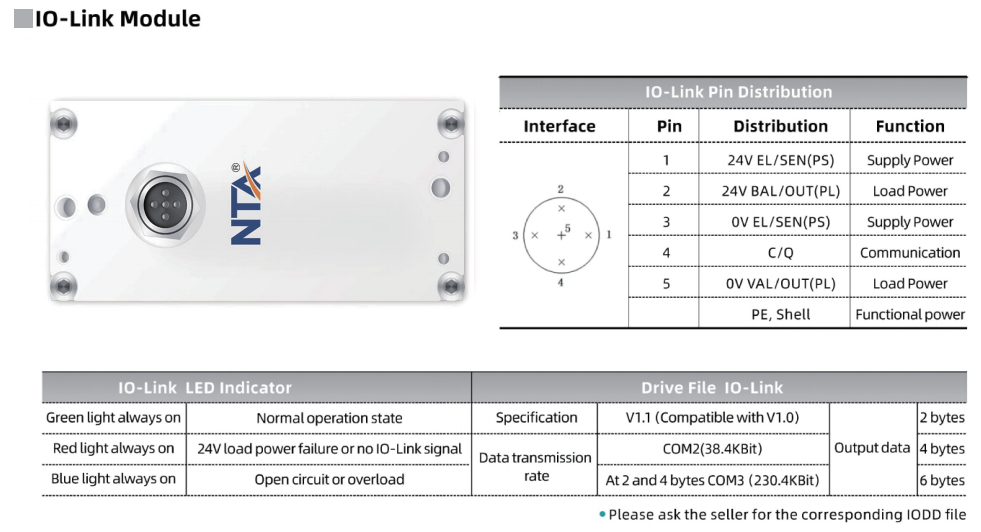

NTA valve terminals featuring IO-Link connectivity allow real-time system supervision and simplified parameter adjustment. Utilizing common cabling infrastructure, they reduce installation complexity, enhance maintenance efficiency, and ensure consistent performance in intelligent industrial automation systems.

Application Scenarios

NTA valve terminals are widely applied in diverse industrial environments where efficiency and control precision are critical. Typical use cases include:

Automotive assembly — ensuring precise motion synchronization and high throughput

Food and beverage packaging — maintaining hygiene and continuous operation

Material handling and conveyors — providing smooth actuation and consistent airflow

Electronics and semiconductor production — requiring compact design and stable performance

Thanks to their flexibility, they are also ideal for industrial air distribution valve terminal systems that demand modular design and quick connectivity.

How Valve Terminals Enhance Productivity

By combining multiple pneumatic functions into one unit, NTA valve terminals simplify control architecture and reduce the number of individual connections. This streamlined structure cuts assembly time, minimizes leaks, and improves response consistency.

Their intelligent configuration and quick reaction capabilities support smart pneumatic valve cluster integration — enabling better process coordination, reduced downtime, and overall higher efficiency in automated production lines.

Quality and Reliability

Every NTA valve terminal is manufactured under a strict quality control system. From precision machining to endurance testing, each product is validated for leakage prevention, durability, and performance stability.

100% functional testing before shipment

Consistent quality tracking and ISO-certified manufacturing process

Continuous R&D for enhanced performance and lifecycle improvement

With this commitment, NTA ensures that customers receive durable modular pneumatic valve connection solutions designed for long-term industrial reliability.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.