Advanced Valve Terminal Systems for Precision Automation and Energy Efficiency — NTA

NTA’s valve terminal systems deliver innovation, stability, and efficiency to meet the growing demands of smart automation. With modular architecture, optimized airflow, and proven reliability, they help industries achieve greater productivity and lower maintenance costs.

Empower your production line with custom-engineered pneumatic control terminal assemblies, and experience how NTA brings precision, flexibility, and lasting performance to intelligent automation.

Product Overview

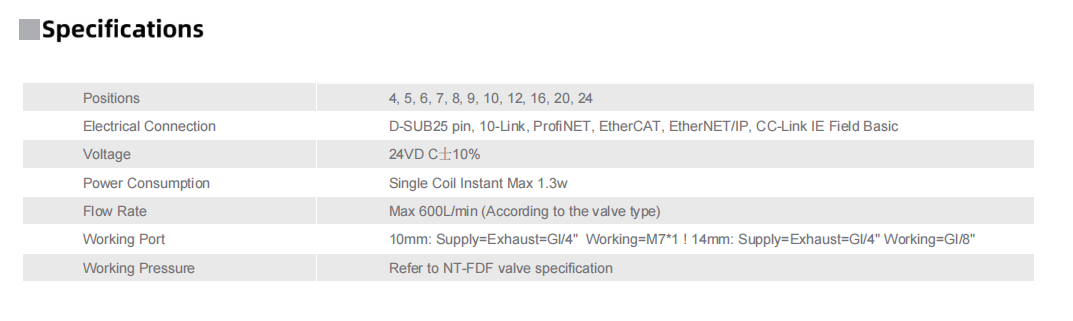

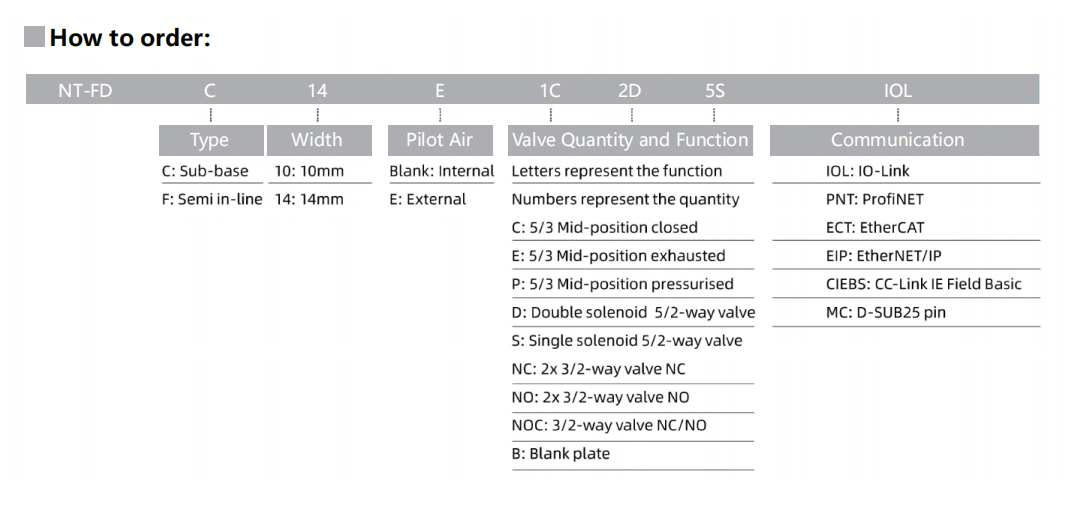

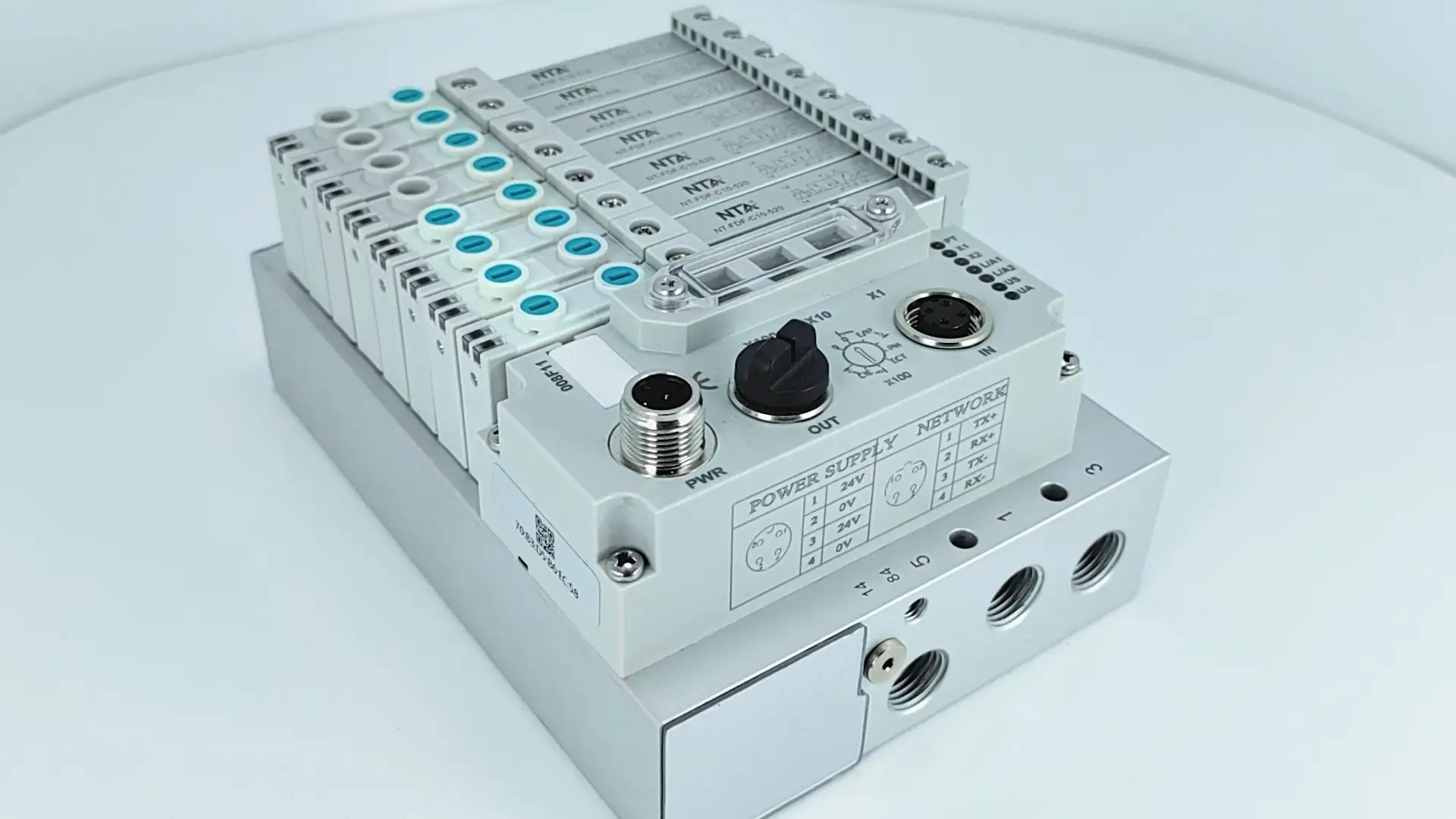

NTA valve terminals integrate multiple solenoid valves into a compact base manifold, reducing wiring complexity and air piping. This unified design enables easy expansion, simplified control, and reduced system maintenance. Each terminal is engineered for stability under continuous operation and ensures accurate pressure control with minimal energy loss.

Manufactured with corrosion-resistant aluminum alloy and high-performance sealing materials, the valves maintain air-tight reliability even in harsh environments, ensuring long-term operation without performance degradation.

Product Features

Modular base design allows flexible valve combinations and scalability

Streamlined air channels ensure high flow efficiency and consistent performance

Quick-connect interfaces for fast assembly and system integration

Low power consumption and fast switching response

Compatible with multiple field communication protocols

These terminals deliver exceptional reliability, making them ideal for multi-channel pneumatic valve integration platforms in modern automation setups.

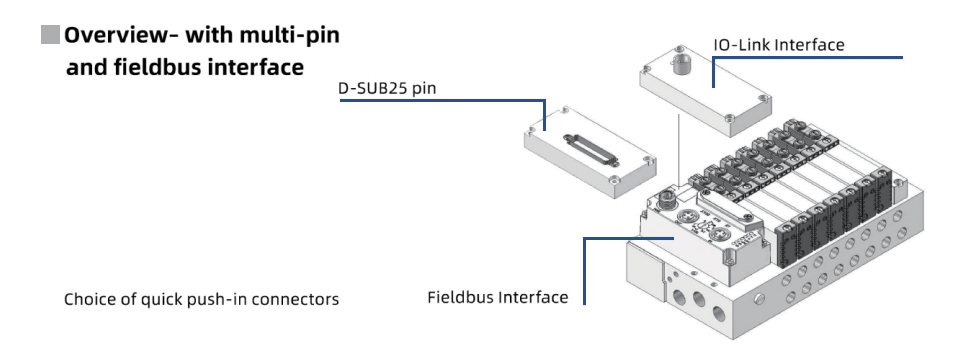

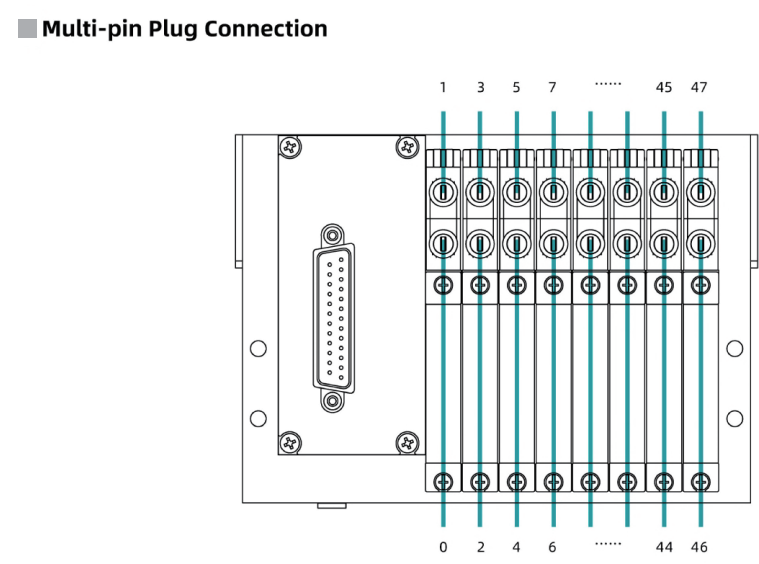

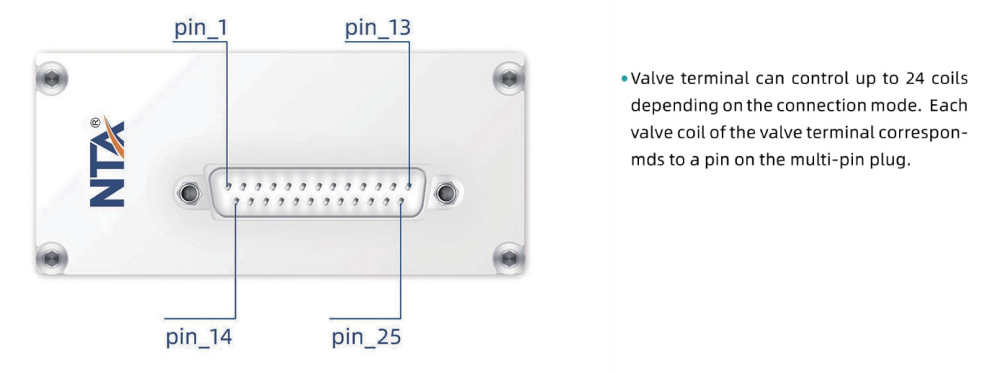

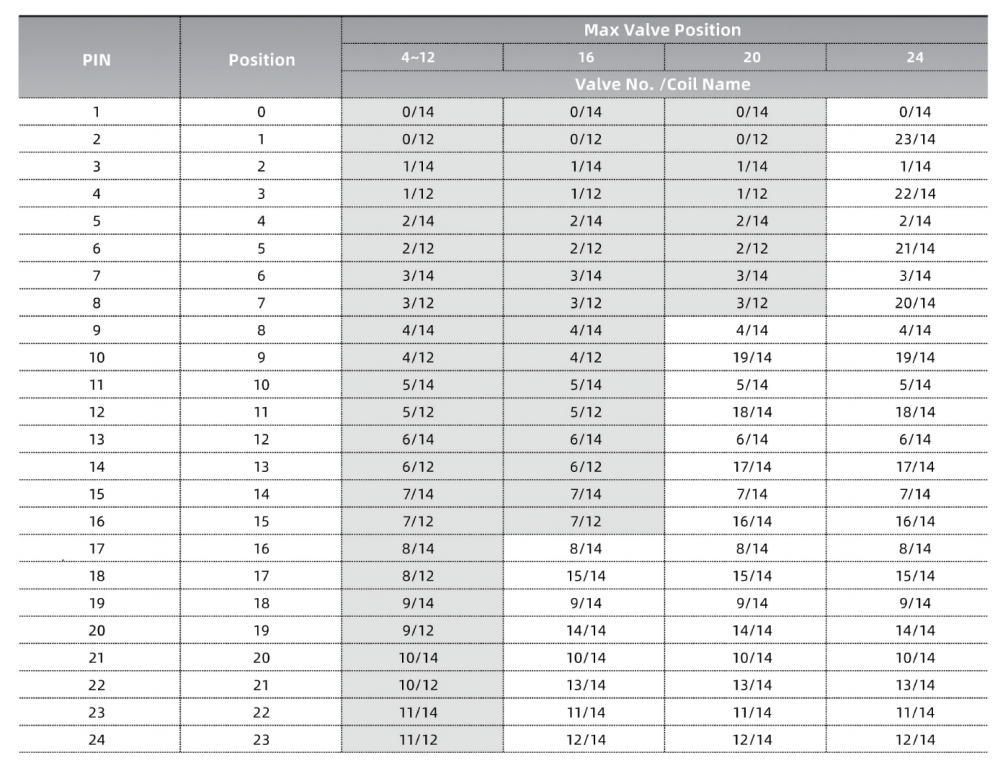

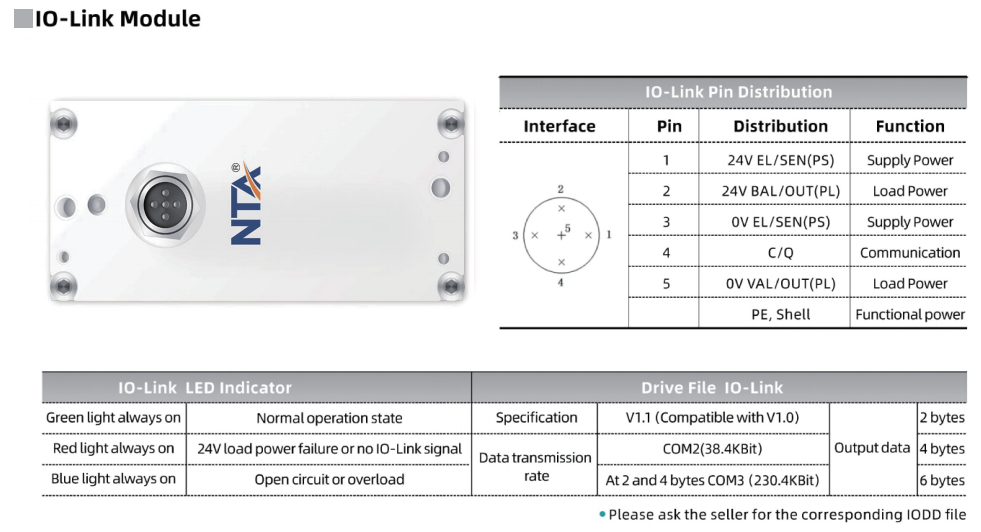

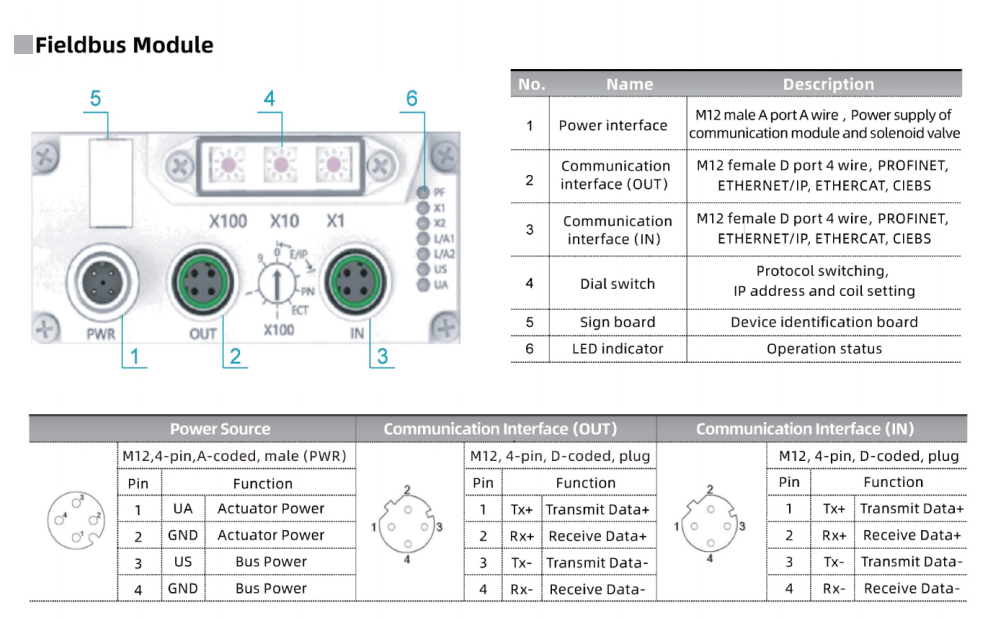

NTA valve terminals come with 25-pin, IO-Link, and Fieldbus interfaces, facilitating seamless system integration, robust communication, and optimized workflow performance in automated production environments.

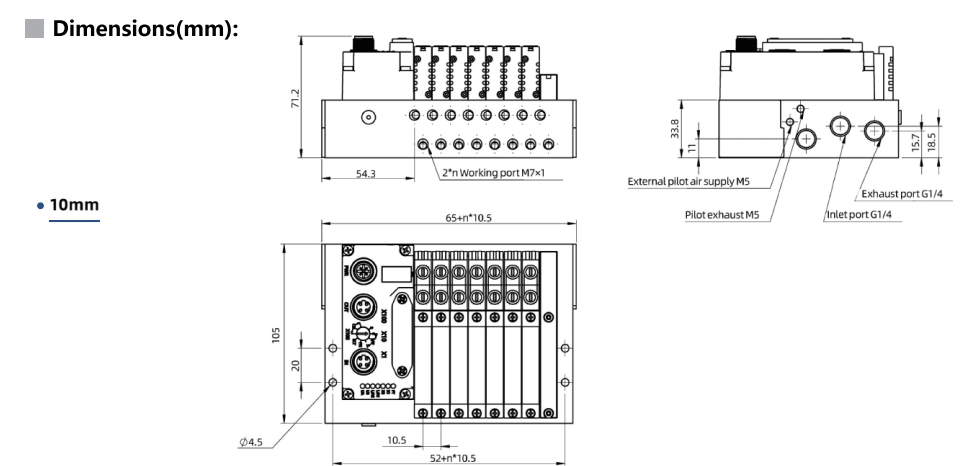

NTA valve terminals are designed with 10 mm solenoid valves in a compact layout, maximizing flow performance while conserving installation space. Their efficient architecture delivers rapid actuation and dependable operation, even in high-demand automation settings.

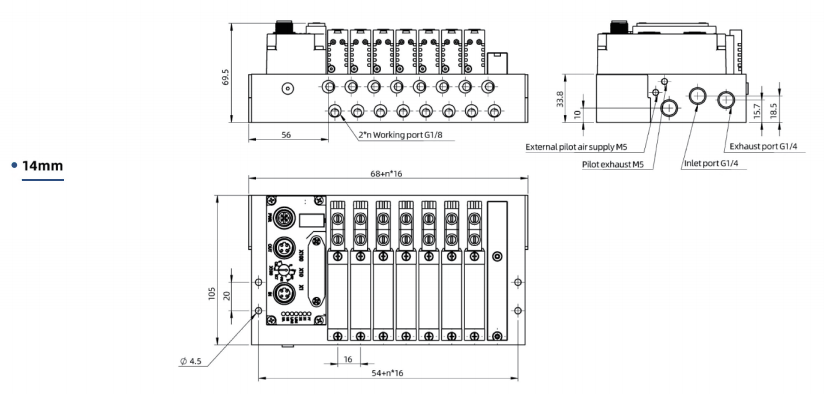

NTA valve terminals utilize 14 mm solenoid valves engineered for enhanced flow capacity and consistent actuation. Ideal for rigorous industrial automation, they provide accurate control, long-lasting reliability, and efficient performance throughout complex manufacturing operations.

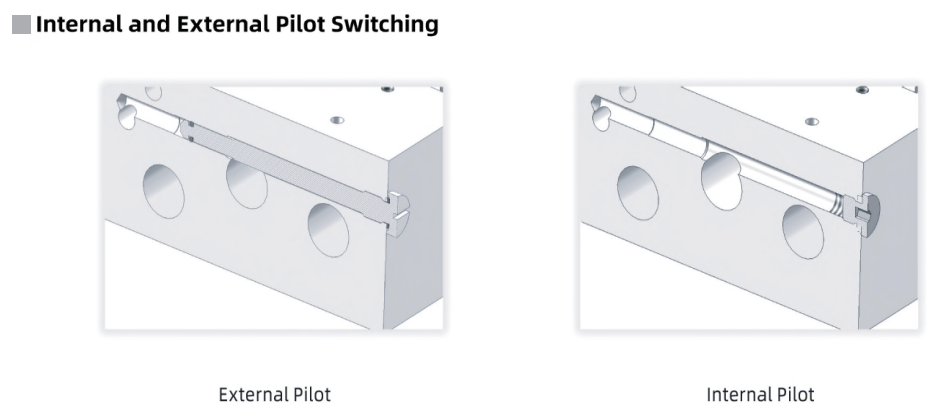

Placing a screw into the pilot port sets the valve to external pilot mode, channeling pilot air through the M5 threaded connection on the base plate. Alternatively, fitting an M5 plug switches the valve to internal pilot mode, drawing pilot air directly from the main supply line.

NTA valve terminals featuring built-in IO-Link functionality allow continuous system monitoring and effortless parameter adjustments. Standardized cabling streamlines installation, enhances predictive maintenance, and ensures reliable operation within intelligent automation networks.

Application Scenarios

NTA valve terminals are widely applied in high-speed production and assembly lines, helping manufacturers improve automation performance:

Automotive manufacturing systems requiring synchronized pneumatic actuation

Pharmaceutical and medical equipment demanding precise pressure control

Packaging and filling machinery with repetitive, high-speed cycles

Logistics and sorting automation where compact pneumatic manifolds save space

Electronic component assembly lines needing stable and low-noise operation

Their compatibility and scalability make them perfect for smart pneumatic control units in digital manufacturing plants.

Enhancing Production Efficiency

By centralizing multiple control valves in one unit, NTA’s valve terminals reduce installation time, wiring effort, and air leakage points. This efficient design enhances signal response speed, ensuring faster actuation and smoother production rhythm.

With built-in diagnostic options and optional communication interfaces, the terminals also support remote monitoring and predictive maintenance. This allows maintenance teams to identify faults early, avoiding costly downtime and ensuring continuous productivity — the essence of energy-optimized pneumatic automation modules in Industry 4.0 systems.

Quality and Reliability

Every NTA valve terminal is produced under a strict quality management system that ensures consistent performance and durability. From component selection to final assembly, each stage undergoes rigorous inspection and testing.

100% leak test and functional validation before shipment

ISO-standardized manufacturing and traceable material sourcing

Enhanced wear resistance for extended valve lifespan

Continuous quality audits to maintain stable global performance

This commitment to precision and quality guarantees long-lasting reliability and confidence for every customer — a hallmark of high-precision modular air control manifolds built for industrial-grade applications.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.