NTA013 Valve Terminal - Smart Modular Pneumatic Valve Control Assemblies

The Valve Terminal NTA013 has five standard wiring packages bringing a world of ease to wiring and maintenance work, while the protective enclosures of three of them conform to IP67 standards for protection from dust and moisture. The use of multi-pin connectors to replace wiring inside manifold blocks provides flexibility when adding stations or changing manifold configuration. The NTA013 series has outstanding response times and long life.

Trusted by automation professionals worldwide, Titan Automation remains committed to delivering smart modular pneumatic valve control assemblies that empower factories to achieve greater efficiency, flexibility, and long-term value.

● Valve Terminal NTA013 optimised for flow rate and communication

● Extended diagnostic functions via CBUS and LED display

● Previous external cabling is now unnecessary, while the installation space remains the same

● Up to 96 valve addresses and up to four voltage zones, three of which can be safely shut off

● For applications with increased safety requirements such as manual work stations

● Control via CPX pneumatic interface with serial communication

● Five valve sizes can be combined on one valve terminal

Product Overview

NTA valve terminals integrate multiple solenoid valves into a single modular platform, simplifying pneumatic circuit management and minimizing wiring complexity. Each terminal features compact design, optimized air paths, and durable construction to ensure consistent airflow and long-term performance.

This integrated configuration reduces installation time and system footprint, making it ideal for applications that require dense layouts and fast response. NTA’s valve terminals combine engineering precision with intelligent functionality, setting a new standard for smart pneumatic valve terminal control units across industrial automation sectors.

Key Product Features

Compact modular layout for flexible configuration and easy expansion

High air flow channels ensuring stable and responsive actuation

Multiple connectivity interfaces supporting modern automation protocols

Durable materials and precision seals ensuring leak-free operation

Simplified maintenance with plug-and-play valve replacement

Designed for performance-driven industries, these features make NTA’s products the preferred choice for high-efficiency pneumatic valve terminal systems used in advanced automation lines.

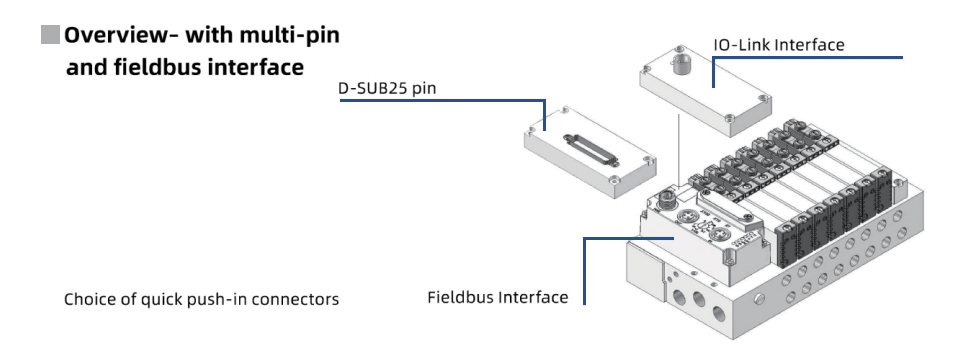

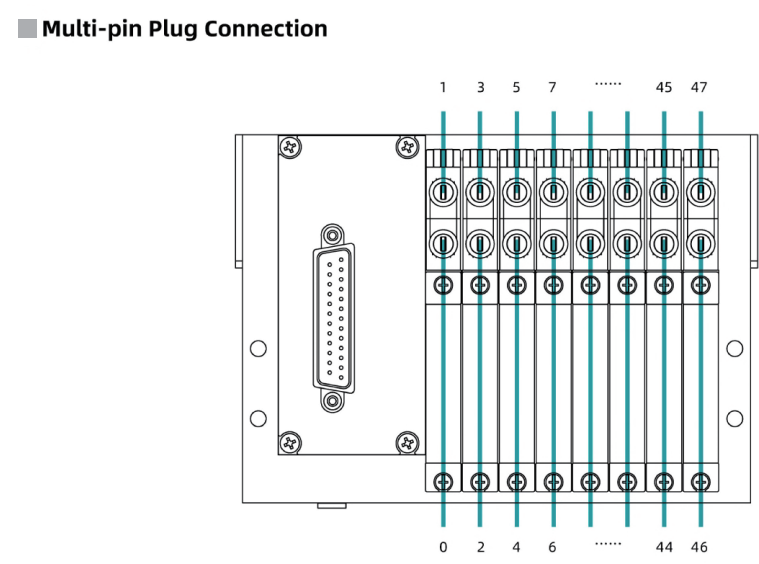

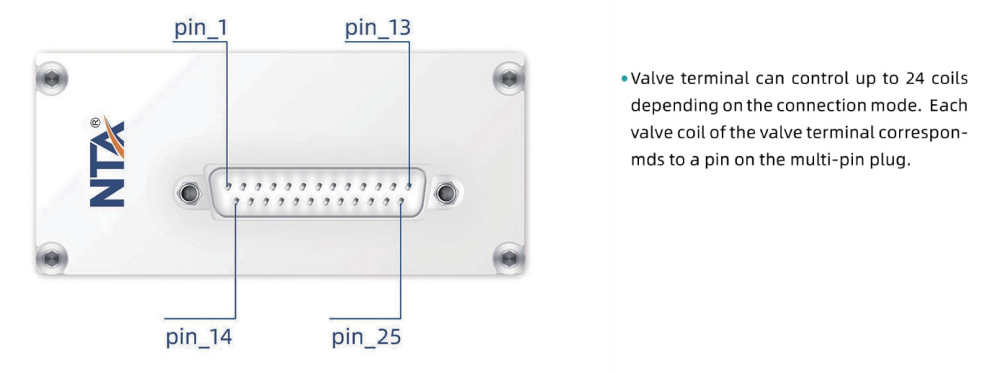

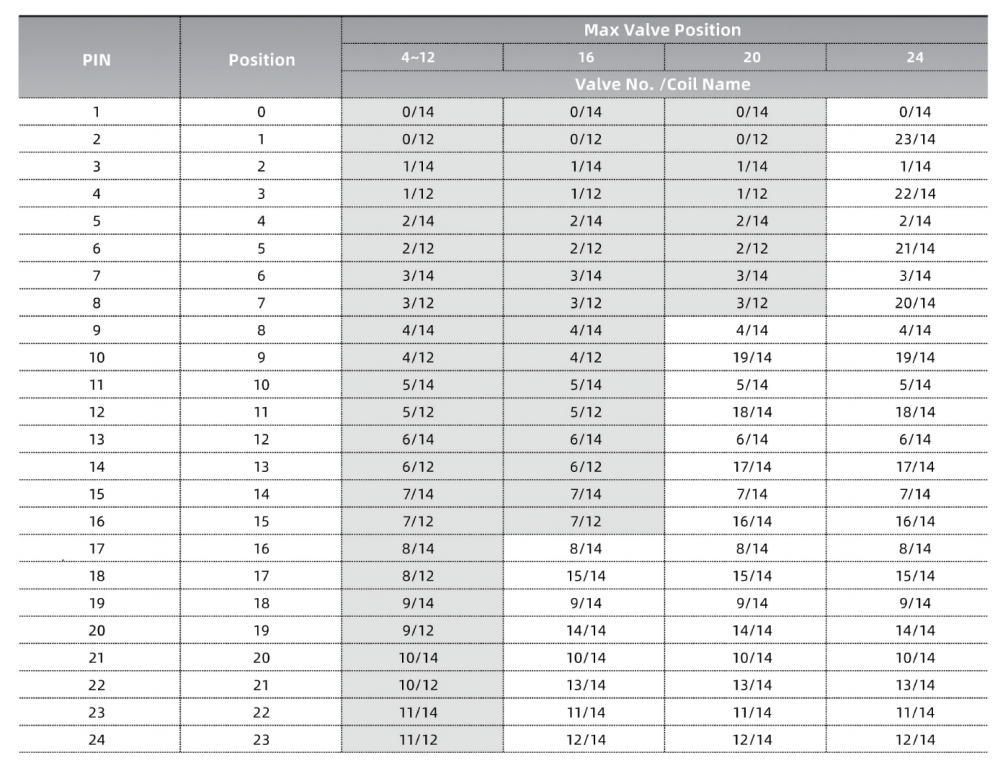

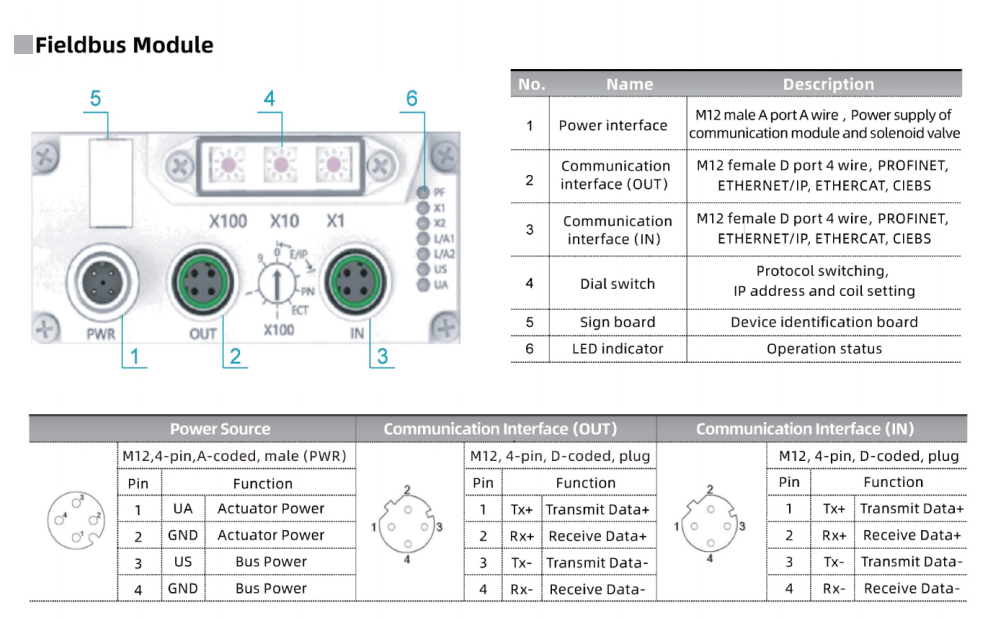

NTA valve terminals offer versatile communication options such as 25-pin, IO-Link, and Fieldbus interfaces, enabling seamless system integration, reliable signal transmission, and enhanced productivity within automated production environments.

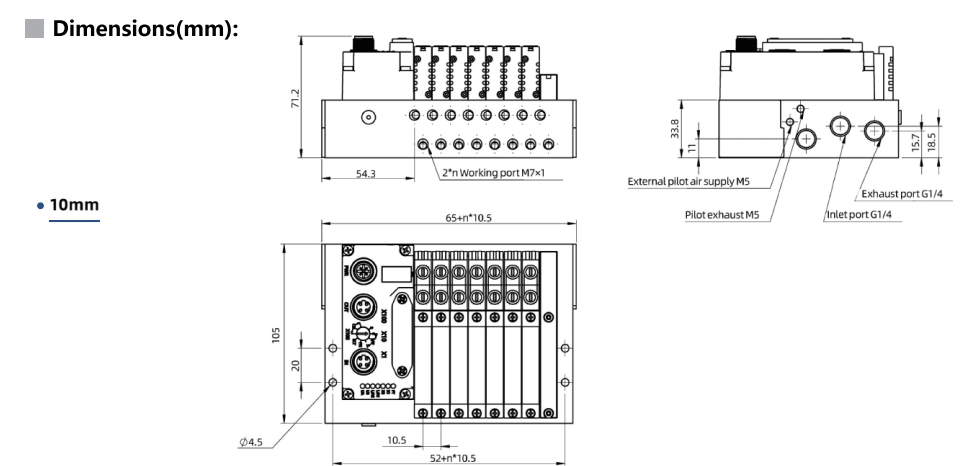

NTA valve terminals are designed with 10 mm solenoid valves in a compact and efficient layout, delivering high flow efficiency while conserving installation space. The refined configuration ensures quick response and dependable operation in high-performance automation applications.

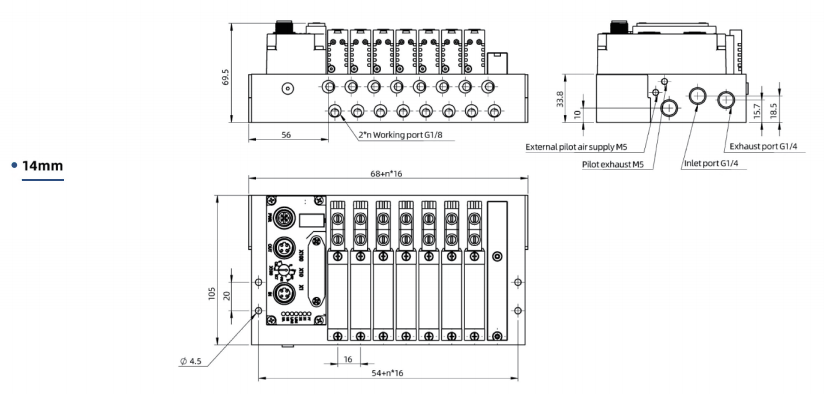

NTA valve terminals incorporate 14 mm solenoid valves designed for high flow efficiency and stable switching performance. Engineered for rigorous automation environments, they ensure precise operation, long service life, and optimal energy efficiency throughout complex manufacturing processes.

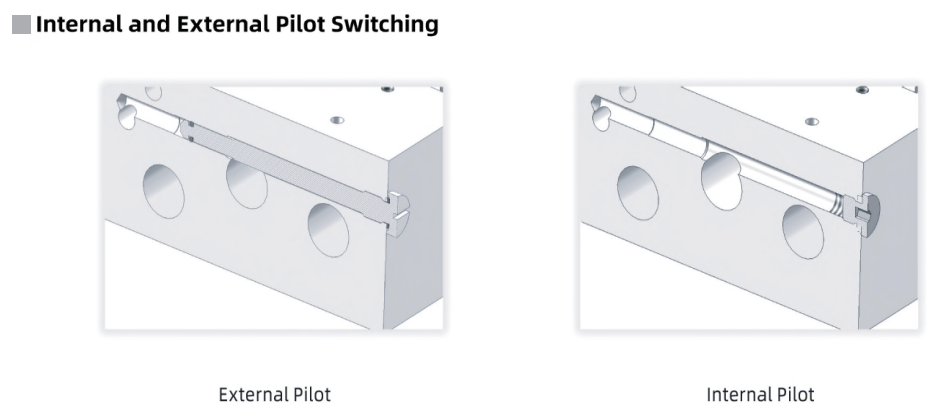

By fitting a screw into the pilot port, the valve is set to operate in external pilot mode, where pilot air is delivered through the M5 threaded connection on the manifold base. Installing an M5 sealing plug converts the system to internal pilot mode, utilizing pilot air from the primary inlet channel for actuation.

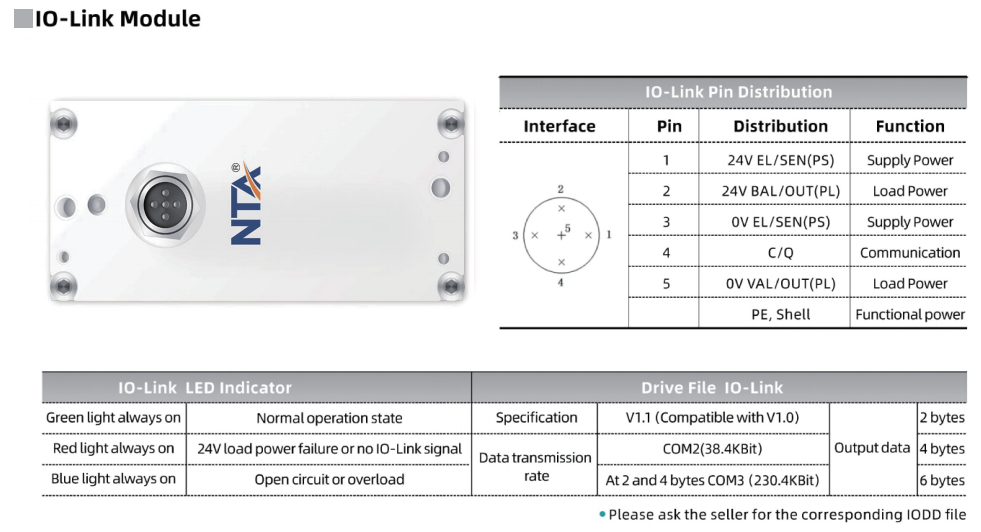

NTA valve terminals integrated with IO-Link communication enable continuous status feedback and simplified parameter configuration. Using standard wiring, they reduce setup complexity, enhance maintenance efficiency, and deliver stable, high-performance operation across intelligent automation systems.

Application Scenarios

NTA valve terminals are widely used in diverse industries such as packaging, automotive, food processing, logistics, and electronics. Their modular design supports customized configurations for different automation requirements.

Common applications include:

Packaging machinery requiring synchronized air control

Automated assembly lines for fast and precise actuation

Conveyor systems with centralized pneumatic distribution

Robotic systems demanding compact, lightweight air control solutions

Each unit’s versatility and reliability make it a trusted choice for industrial pneumatic valve networking solutions in smart factories.

Advantages of NTA Valve Terminals

NTA valve terminals deliver more than just pneumatic control—they drive process optimization. By integrating multiple valves and control channels into one platform, system wiring is significantly reduced, while real-time signal feedback enhances monitoring accuracy.

The result is faster installation, simplified maintenance, and greater uptime for production systems. Additionally, NTA’s valve terminals use energy-efficient flow designs that reduce air consumption and extend service life, making them ideal for energy-optimized automation valve terminal assemblies.

Quality and Reliability

All NTA valve terminals are produced under rigorous ISO-compliant standards. Each product undergoes strict air leakage testing, electrical endurance checks, and operational validation before shipment.

Our advanced production line and automated inspection systems guarantee precision assembly and stable quality in every batch. With continuous improvement in process control, NTA provides precision-engineered pneumatic distribution valve platforms that perform reliably under demanding industrial environments.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.