Product Description

Titan Automation's valve terminals combine multiple solenoid valves into a single, compact unit, simplifying system architecture and reducing installation time. The modular structure allows easy configuration and quick expansion, while high-quality materials ensure consistent airflow and long service life.

Each unit is engineered to maintain optimal sealing and minimize energy loss, helping manufacturers achieve stable pneumatic control in high-speed automated environments. This makes Titan Automation an ideal partner for industrial modular pneumatic valve array solutions across sectors such as robotics, logistics, packaging, and electronics.

The valves Terminal used in our company’s valve terminal has excellent performance, with an operating life of up to 80 million cycles, effectively reducing equipment maintenance frequency. Its response time is only 20ms, and the highest operating frequency can reach 15Hz, ensuring fast response and efficient control. In addition, the solenoid valve’s coil power is only 0.6W, which generates less heat, operates more stably, and extends service life. With IP67 protection, it can operate stably in harsh environments and meet various application requirements. What’s more, the valve terminals supports a drive speed of 300mm/s for up to 63mm cylinders, and can also drive 125mm cylinders at 100mm/s, providing powerful pneumatic control and ensuring efficient execution of the system.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 9]()

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 10]()

Key Features

- Compact modular design that allows flexible assembly and reduced footprint

- High response solenoid valves ensure precise control and fast actuation

- Integrated interfaces for easy connection and data communication

- Durable construction using corrosion-resistant materials for long-term use

- Easy maintenance with quick valve replacement and fault detection

These features enable efficient operation in automated pneumatic control system assemblies, supporting demanding production lines that require both speed and stability.

Say Goodbye To The Limitations Of Traditional Solenoid Valves!

Traditional solenoid valve control systems are complex to install, cumbersome to assemble and wire, requiring the separate placement of multiple valve bodies and pipelines, making construction difficult. Furthermore, they involve numerous parts and accessories, making procurement cumbersome and prone to errors during maintenance. In addition, traditional solenoid valves have poor scalability; adding valve positions usually requires rewiring or equipment replacement, lacking flexibility. Moreover, they lack intelligent diagnostic functions; once a fault occurs, troubleshooting must be done step-by-step, resulting in low maintenance efficiency and impacting production schedules.

Titan Automation valve terminals adopt a modular design, enabling quick installation, flexible expansion, and equipped with fault diagnostic functions, making automated control more efficient and reliable.

Titan Automation valve terminals are widely used in various automation control systems due to their high level of integration, fast response time, and compatibility with multiple protocols and interfaces. Whether it’s a high-precision production facility or a large-scale production line, Decowell valve islands provide a stable and efficient solution to improve equipment performance and productivity.

Titan Automation Specialty Valve Terminal Manufacturing

Titan Auotmation as a professional manufacturer of pneumatic valve terminal, is committed to providing high-performance, stable and reliable automation control solutions for global customers with strong production capacity, technological innovation and strict quality management.

- We have modernized production bases and automated production lines to ensure stable manufacturing and fast delivery.

- We offer customized solutions that are flexibly adapted to the needs of our customers.

- Through the ISO quality system certification, all products are strictly tested to ensure long-term stable operation.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 15]()

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 16]()

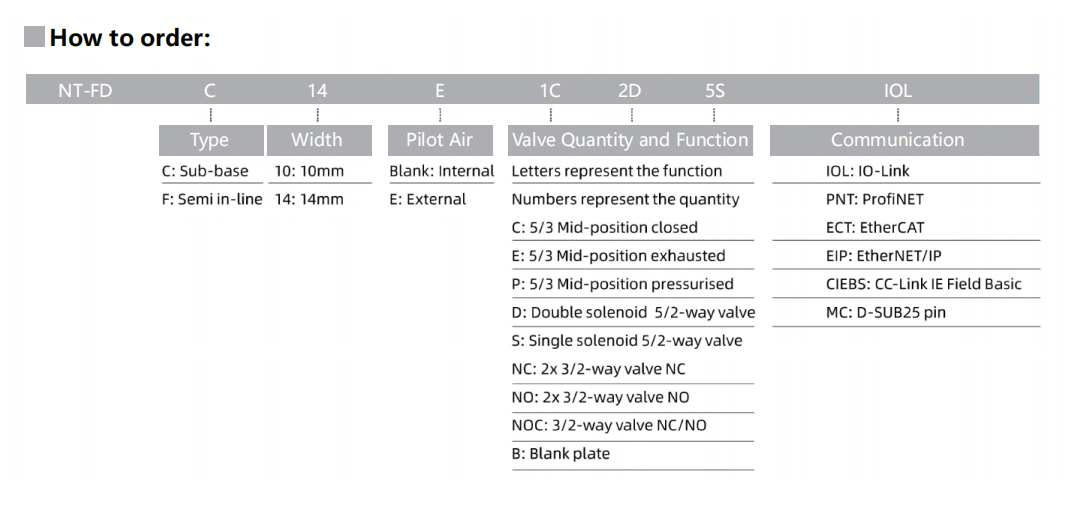

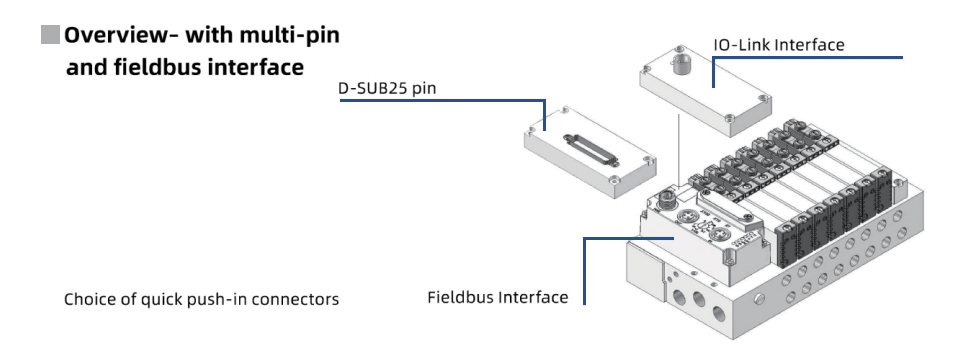

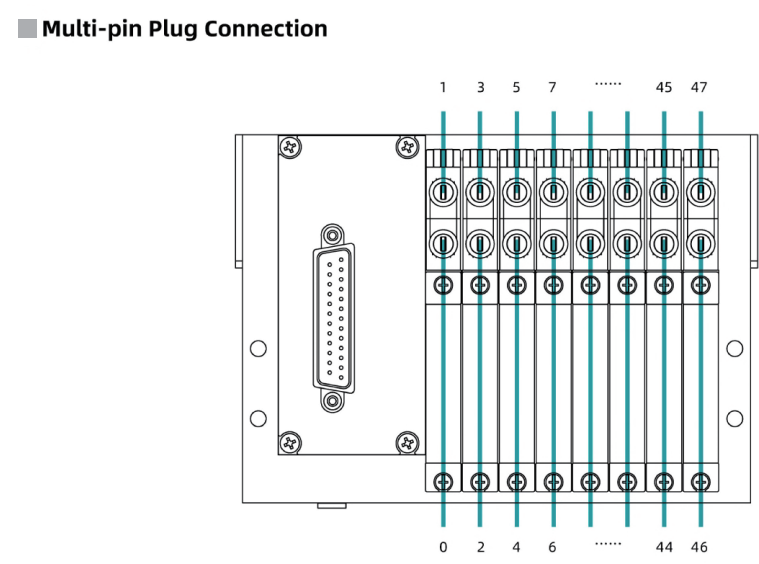

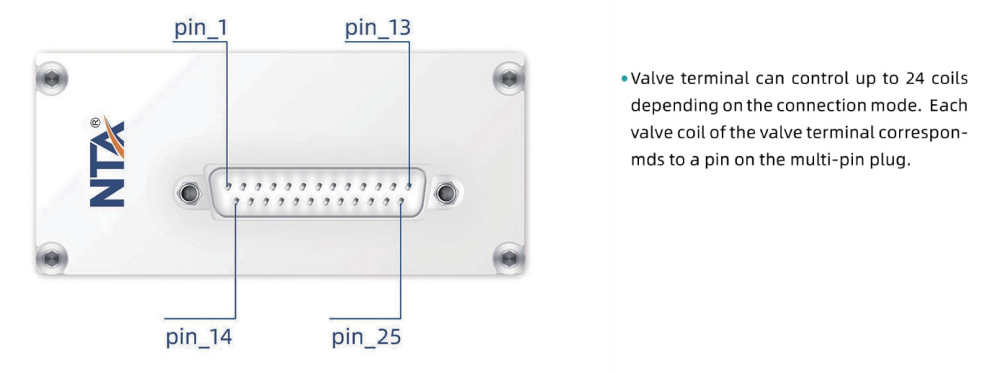

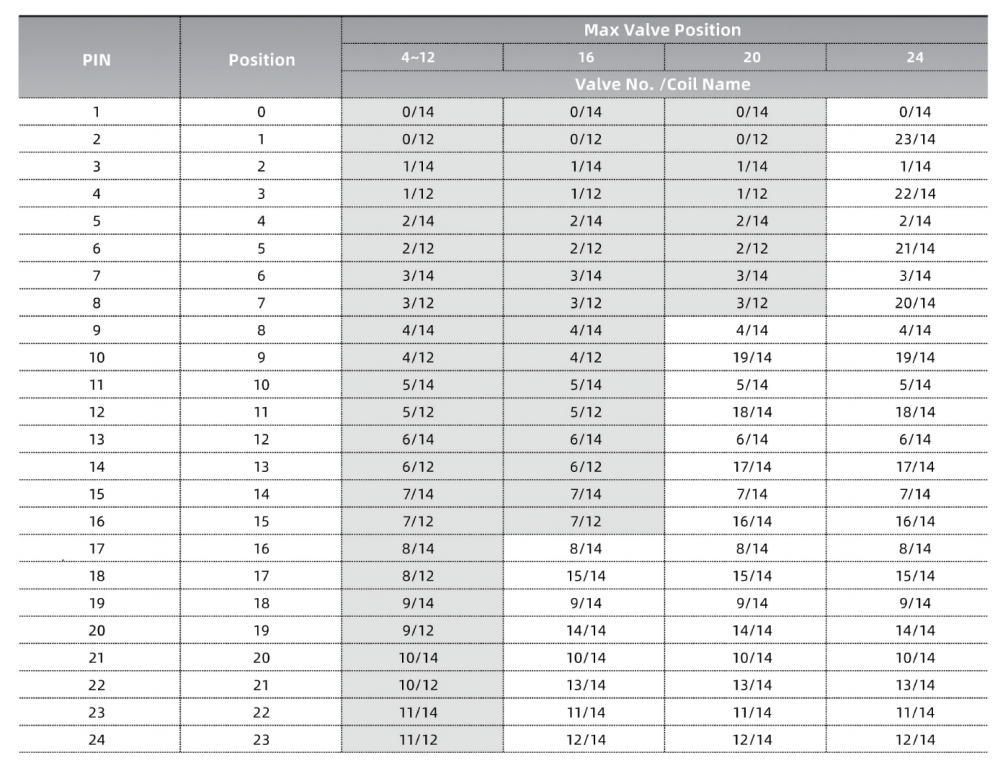

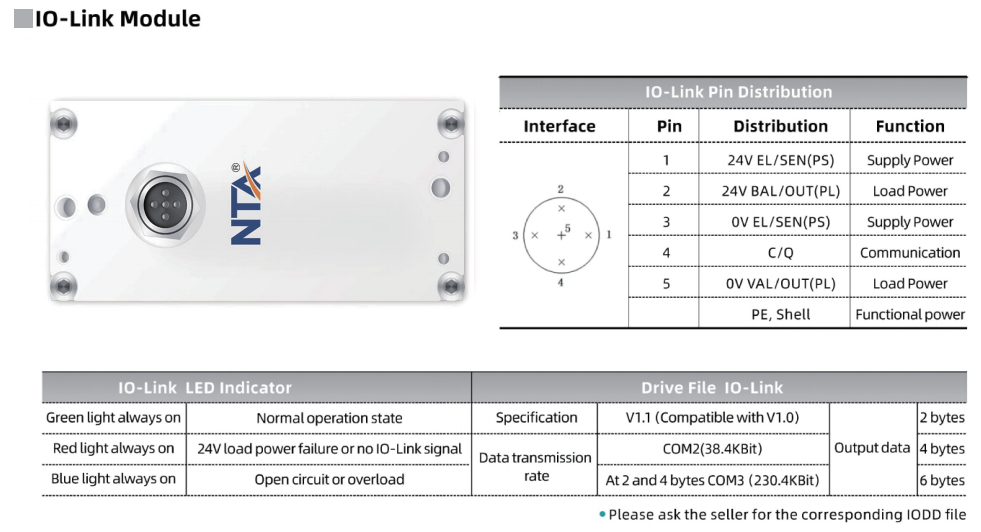

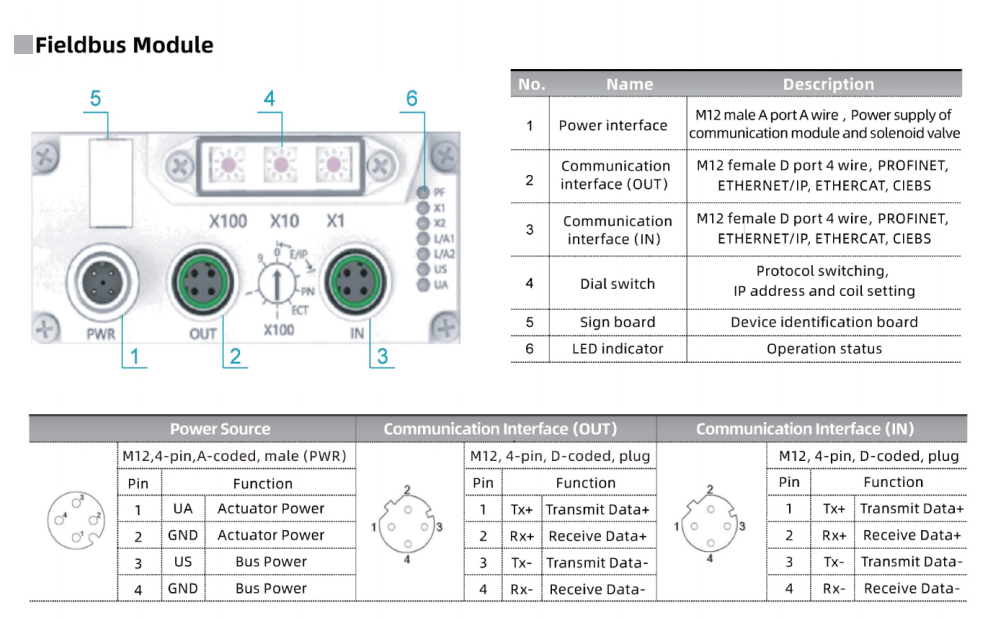

Titan Automation valve terminals support multiple communication standards, including 25-pin, IO-Link, and Fieldbus interfaces, allowing effortless integration, secure data transfer, and improved operational efficiency across automated manufacturing systems.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 17]()

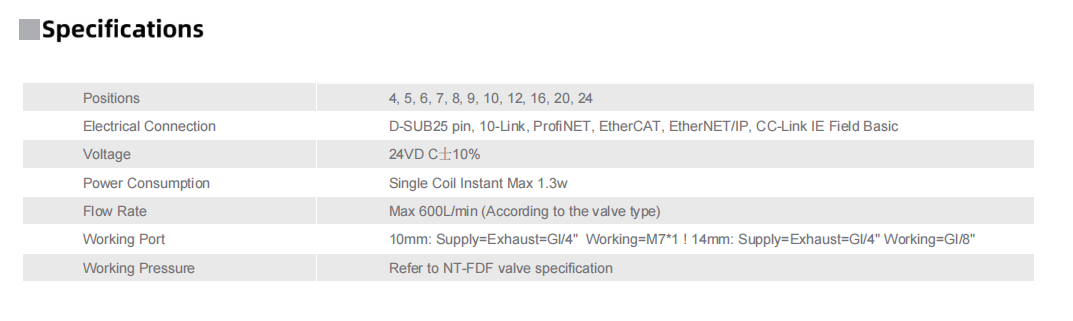

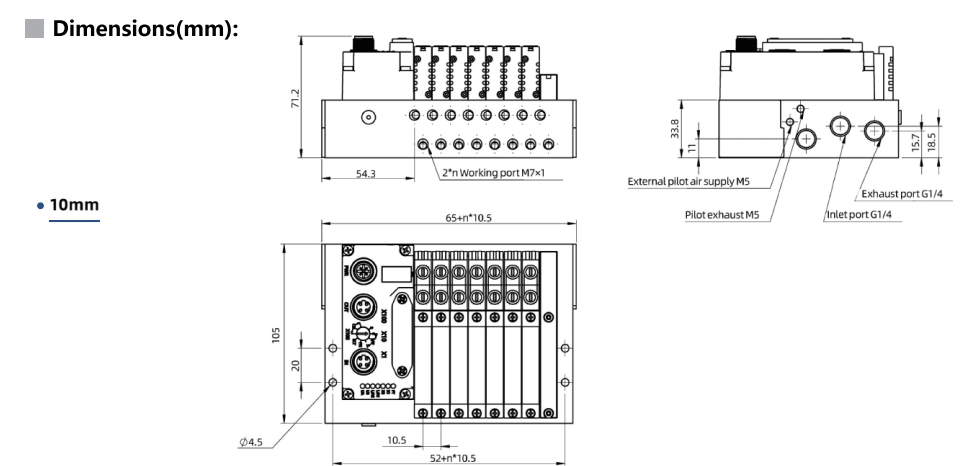

Titan Automation valve terminals utilize 10 mm solenoid valves arranged in a highly efficient compact structure, achieving excellent airflow while minimizing installation footprint. Their optimized design provides fast switching response and reliable performance under demanding automation conditions.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 18]()

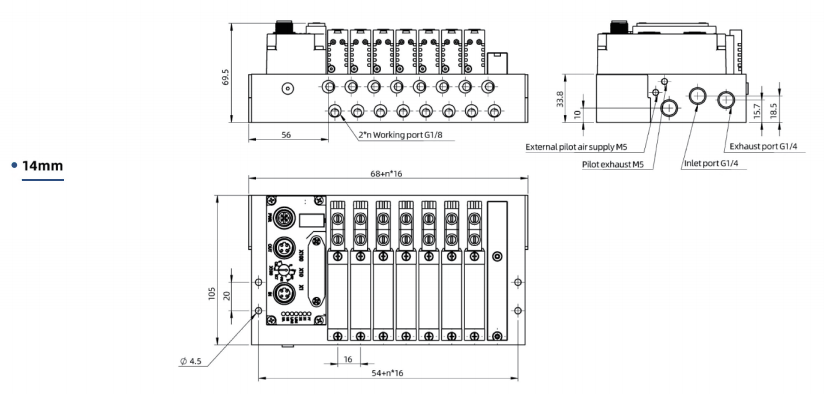

Titan Automation valve terminals feature 14 mm solenoid valves optimized for enhanced flow and reliable actuation. Built for demanding industrial automation applications, they deliver accurate control, exceptional durability, and efficient operation across advanced production lines.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 19]()

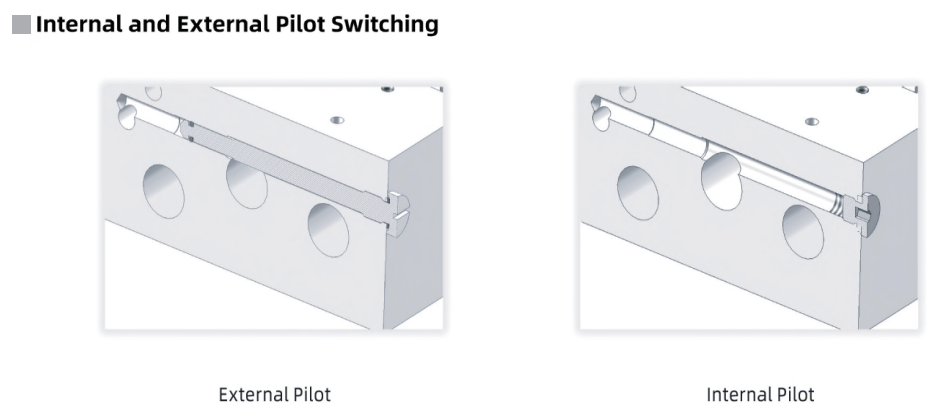

Inserting a screw into the pilot port configures the valve for external pilot operation, supplying pilot air via the M5 threaded port on the base plate. Switching to an M5 plug reconfigures the valve to internal pilot mode, sourcing pilot air directly from the main supply.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 20]()

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 21]()

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 22]()

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 23]()

Titan Automation valve terminals with integrated IO-Link technology provide real-time system monitoring and easy parameter adjustment. Utilizing conventional cabling, they streamline installation, support proactive maintenance, and ensure dependable performance in modern automation networks.

![Titan Automation Pneumatic Valve Terminal 24V DC 42-112psi Multi-pole 24]()

Application

Titan Automation valve terminals are widely applied in industrial sectors requiring complex pneumatic coordination and space efficiency. Common applications include:

- Packaging machinery — enabling synchronized motion and faster cycles

- Automated assembly systems — providing accurate air control for high-speed operations

- Material transport and conveyors — improving responsiveness and process continuity

- Robotic production lines — allowing multi-axis control and compact integration

Our valve terminals are trusted for custom pneumatic valve management platforms, helping users achieve precision control and simplified maintenance in intelligent automation systems.

FAQs

1. How do I perform maintenance and troubleshooting on a valve terminal?

Titan Automation Valve terminal supports intelligent diagnostic function, which can monitor the working status in real time and provide fault alarms. Users can view the operation remotely through the bus, so as to maintain in time and reduce the downtime.

2. How does a valve terminal communicate with a PLC?

Titan Automation valve terminal supports bus control, can communicate directly with PLC through EtherCAT, PROFIBUS, Modbus, EtherNet/IP and other protocols, and data interaction through I/O modules or HMI to realize intelligent control.

3. What brands of PLCs are your valve terminal compatible with?

Our valve terminal are compatible with PLCs from Siemens, Mitsubishi, Omron, Schneider, Beckhoff, Rockwell and many other brands for efficient integration.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.