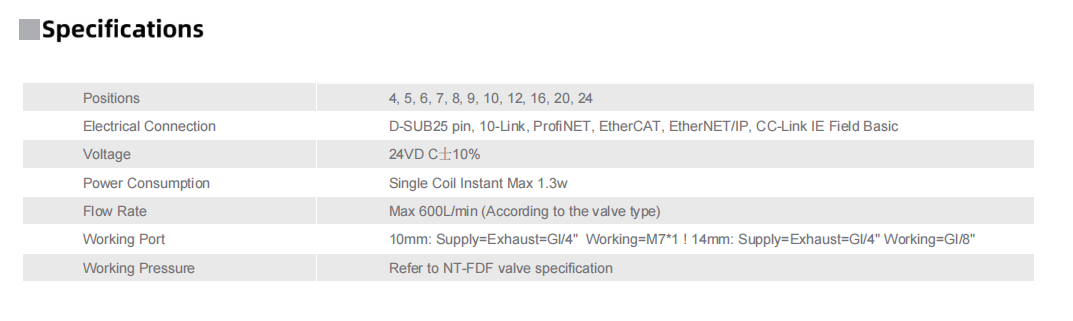

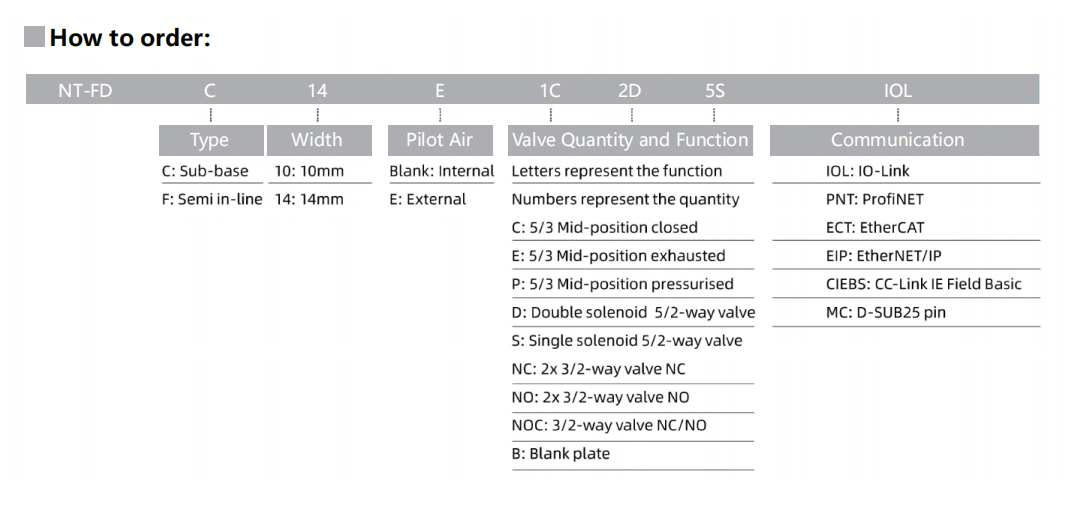

Pneumatic Valve Terminal NTA012 Series 4/3-way 10 mm Solenoid Valves

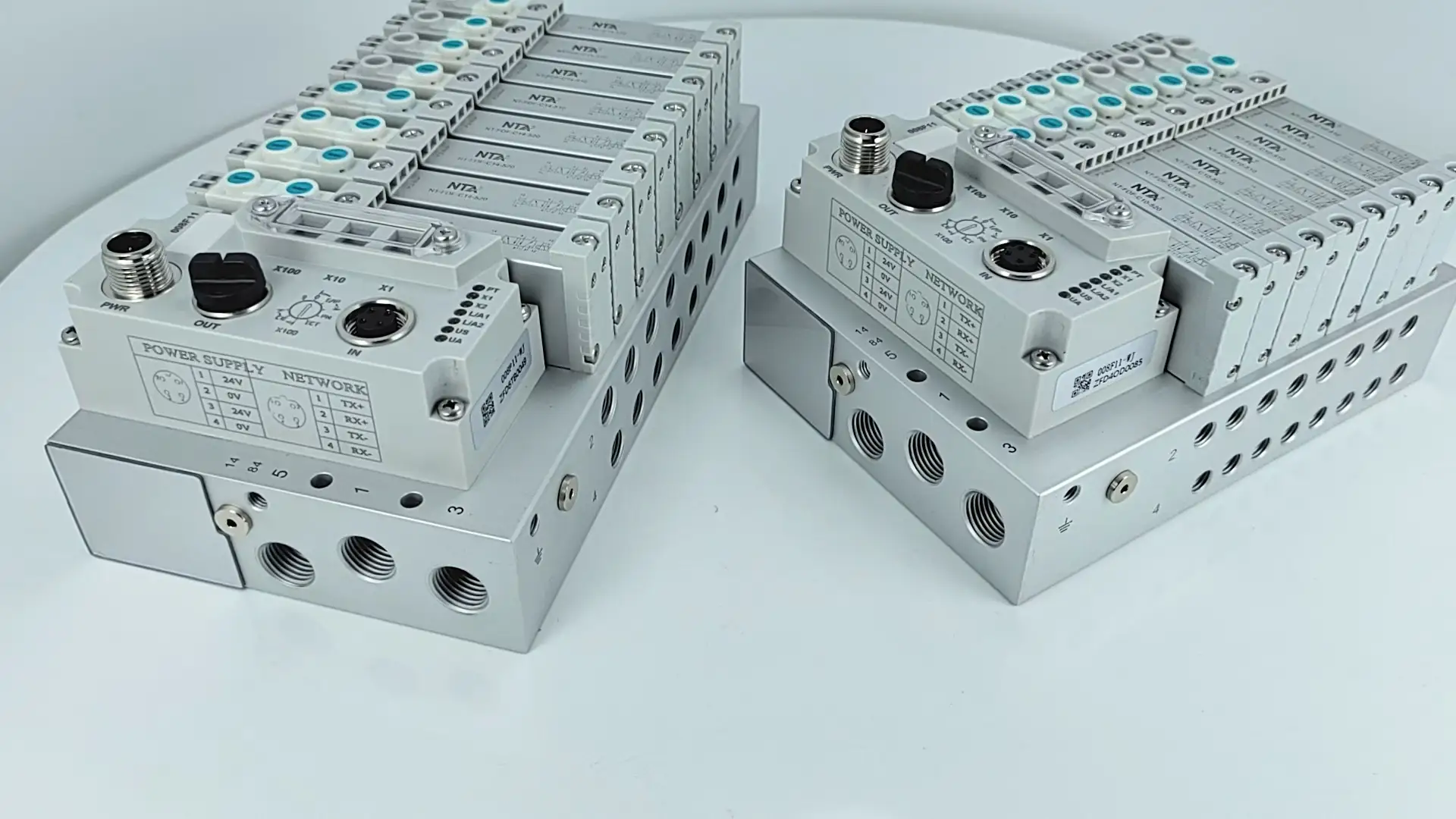

At Titan Automation, we’re thrilled to introduce valve terminals, a revolutionary addition to industrial automation. Designed to enhance machine performance and streamline OEM installation processes, the valve terminal NTA012 Series combines versatility, efficiency, and durability into one compact, IP65/67-rated package.

The Titan Automation valve terminal is engineered for high performance in demanding environments. Its lightweight, high-performance polymer construction ensures durability, while its compact size makes it an ideal solution for conserving space in machines or control cabinets.

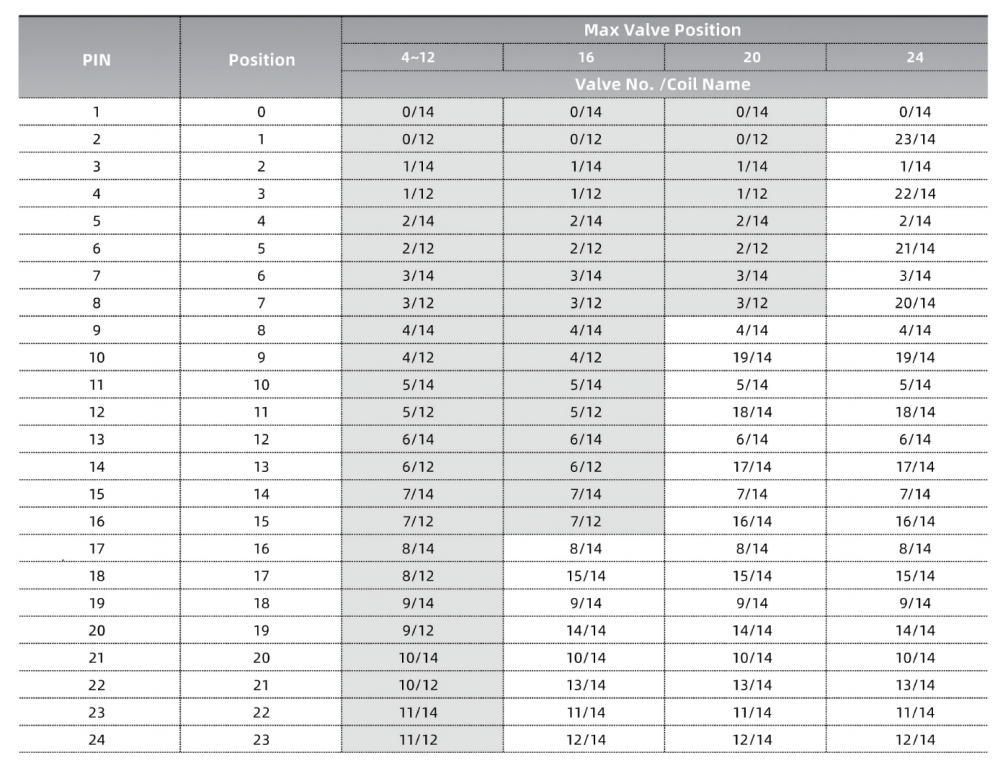

What sets the valve terminal NTA012 apart is its modular design, which simplifies inventory management and reduces overhead costs. By offering a single valve model that fits both high-flow and compact sub-bases, Festo makes ordering, stocking, and maintenance straightforward. With the flexibility to mix and match one- or four-position sub-bases, valve terminal NTA012 can handle up to 128 valves and 128 solenoid coils, ensuring scalability for a wide range of applications.

Product Overview

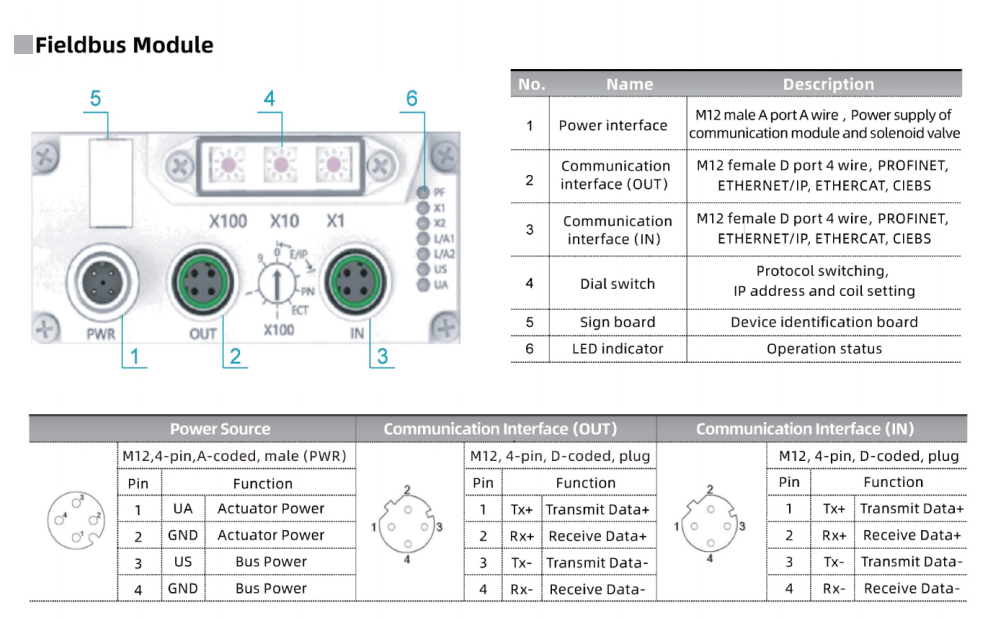

NTA valve terminals combine multiple solenoid valves into a modular and compact design, enabling efficient centralized control. Each valve manifold supports fast response time, optimized air pathways, and reliable switching performance.

Their space-saving structure minimizes piping and wiring, reducing both installation time and maintenance complexity. Built with corrosion-resistant aluminum alloy and precision-engineered sealing materials, these terminals ensure long-term stability and energy-efficient operation under demanding industrial conditions.

Key Product Features

Compact modular layout for flexible configuration and quick assembly

Enhanced airflow channels for consistent, high-speed performance

Optional electrical interfaces for diverse automation systems

Energy-saving valve design reduces air loss and operating costs

Long service life with minimal maintenance requirements

With these features, NTA systems deliver precise control and stable actuation, making them ideal for industrial pneumatic valve automation systems that demand speed, accuracy, and efficiency.

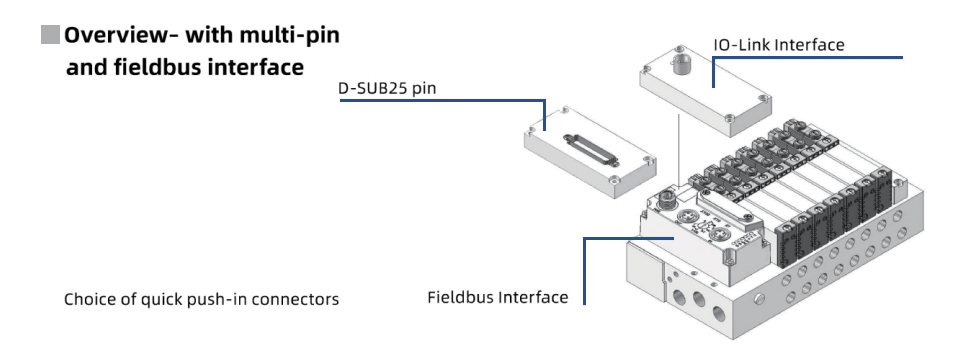

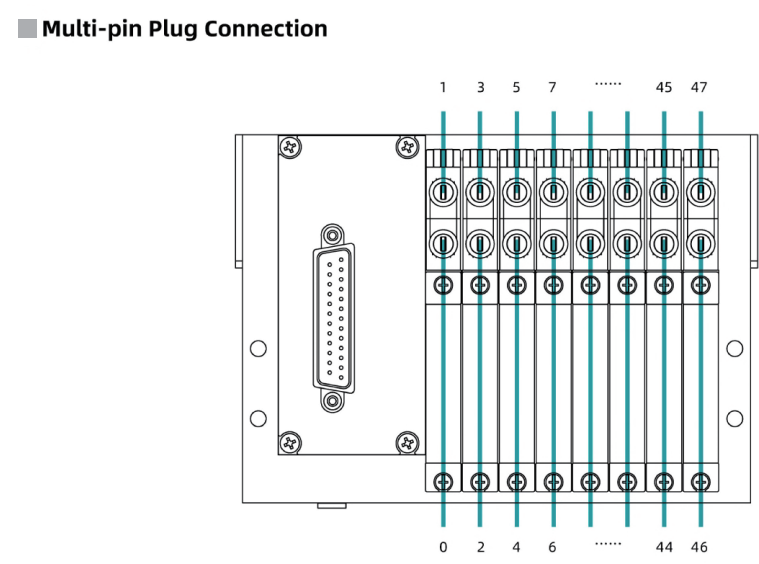

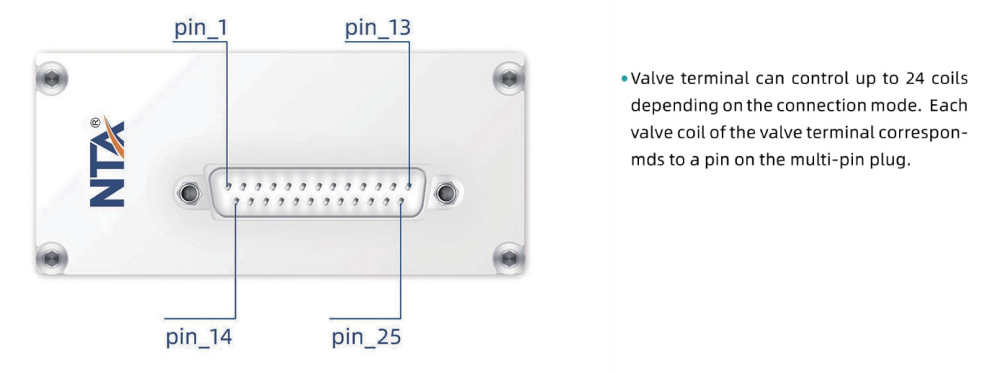

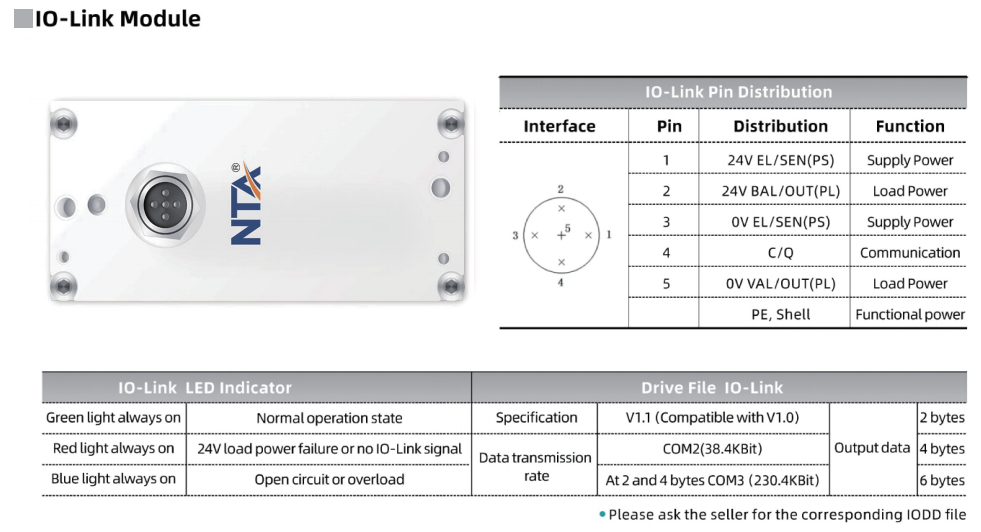

NTA valve terminals provide connectivity via 25-pin, IO-Link, and Fieldbus interfaces, enabling smooth system integration, dependable communication, and optimized performance throughout automated production processes.

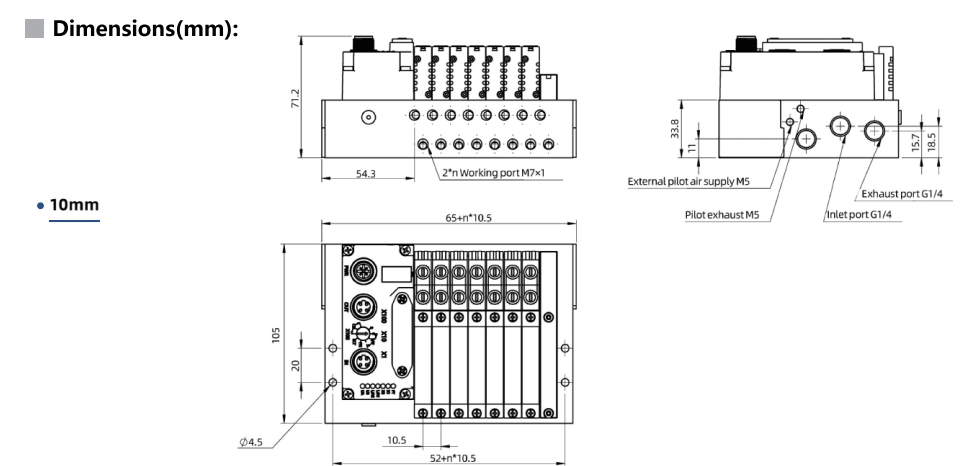

NTA valve terminals are equipped with 10 mm solenoid valves in a compact arrangement, delivering efficient flow performance while reducing required installation space. This intelligent design ensures rapid actuation and dependable operation in challenging automation environments.

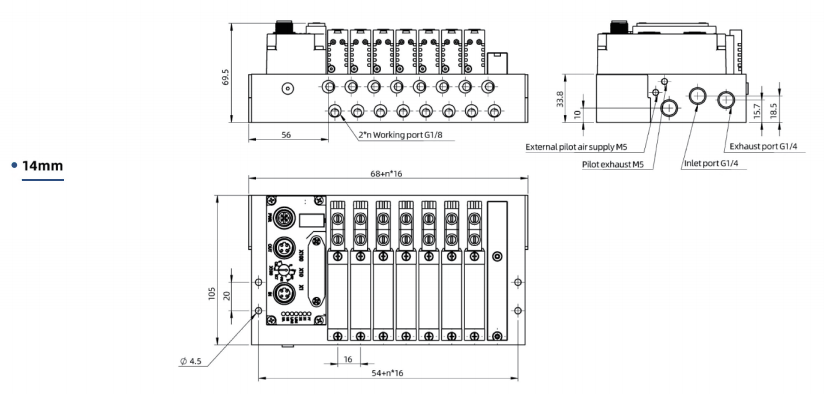

NTA valve terminals integrate 14 mm solenoid valves engineered for superior flow capacity and consistent switching. Designed for intensive industrial automation, they provide precise control, long-term reliability, and high-efficiency performance throughout complex manufacturing systems.

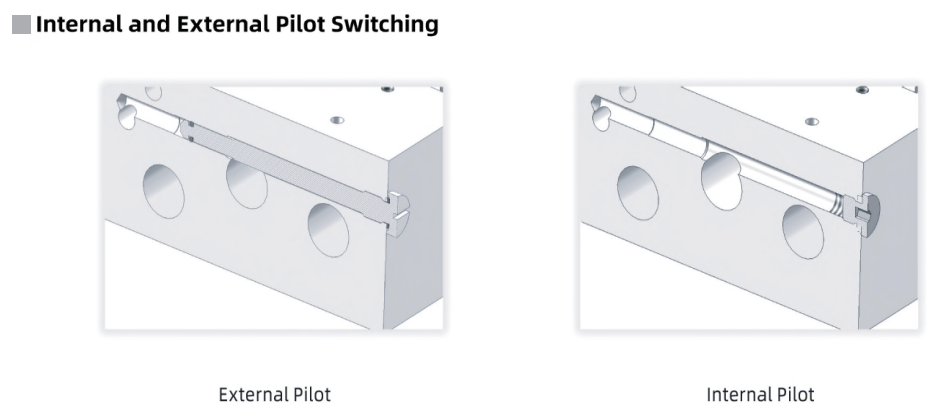

Installing a screw in the pilot port sets the valve to external pilot mode, directing pilot air through the M5 threaded connection on the base plate. Replacing the screw with an M5 plug switches the valve to internal pilot mode, drawing pilot air directly from the main inlet.

Equipped with IO-Link modules, NTA valve terminals enable continuous system monitoring and straightforward parameter configuration. Leveraging standard cabling, they simplify installation, facilitate predictive maintenance, and maintain reliable operation within advanced automation networks.

Application Fields

NTA valve terminals are widely applied across industries where reliability and precision are essential:

Automotive assembly lines requiring synchronized pneumatic movement

Food and beverage packaging for hygienic, high-speed processes

Material handling and warehouse logistics with dynamic automation systems

Robotic integration platforms demanding compact, centralized air control

Electronics and semiconductor manufacturing requiring consistent, low-vibration actuation

Engineered to meet the needs of evolving automation systems, they are also an excellent choice for adaptive pneumatic control systems for manufacturing plants.

Performance and Efficiency

By consolidating multiple pneumatic functions into a single terminal block, NTA valve terminals reduce air consumption and optimize response time. The internal air channels are precision-machined for smooth flow and minimal pressure drop, ensuring continuous high performance even in multi-axis automation lines.

This integrated approach boosts overall plant productivity and enables real-time system monitoring, aligning perfectly with the goals of smart modular pneumatic distribution systems that support Industry 4.0 connectivity and flexibility.

Quality and Reliability

At NTA, every valve terminal is manufactured under a strict quality control framework. From raw material selection to final testing, each component meets global standards to ensure durability and long-term reliability.

ISO-compliant production and assembly processes

100% performance and leakage testing before delivery

Consistent batch control for traceable quality assurance

Continuous product improvement for enhanced lifecycle performance

This commitment guarantees reliable and repeatable operation, meeting the demands of precision-engineered pneumatic valve manifold systems used in advanced industrial environments.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.