Smart Pneumatic Valve Terminals for Efficient Industrial Automation — NTA

NTA valve terminals are built to meet the evolving needs of smart factories — offering modularity, reliability, and seamless connectivity. With their high adaptability and proven quality, these terminals help industries optimize control efficiency, reduce costs, and achieve stable production performance.

Choose NTA’s compact automation pneumatic valve assemblies to experience intelligent control, robust construction, and enduring value in every automation project.

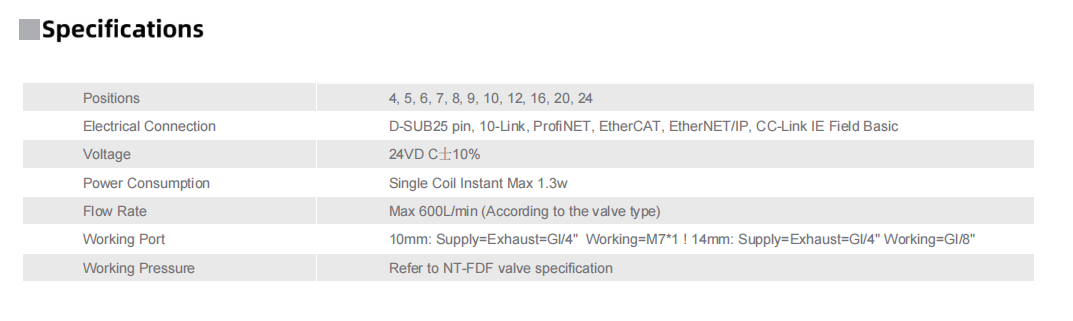

Product Overview

NTA valve terminals are designed for flexibility, compactness, and smooth operation. Each unit integrates multiple control valves on a common base, reducing the need for complex tubing and electrical wiring. This modular concept allows engineers to quickly configure or expand systems according to project needs.

Built with high-quality aluminum alloy and precision sealing components, the valve terminals maintain excellent air-tight performance even in demanding production environments. Whether installed in robotic arms, packaging machines, or automated testing lines, they ensure consistent operation and minimal downtime.

Product Features

Compact and lightweight modular design for easy installation

Efficient airflow design ensures rapid actuation and stable output pressure

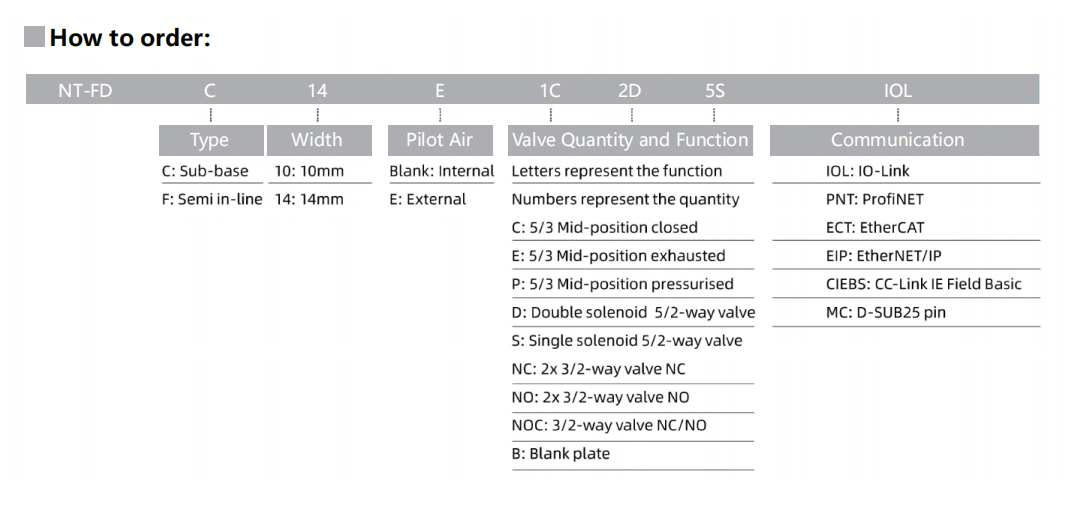

Flexible electrical interface options for diverse control systems

Reliable sealing structure to prevent leakage under continuous operation

Simple maintenance and fast valve replacement to minimize downtime

NTA’s industrial modular pneumatic valve clusters are specifically engineered to help users streamline system architecture and reduce total operating costs.

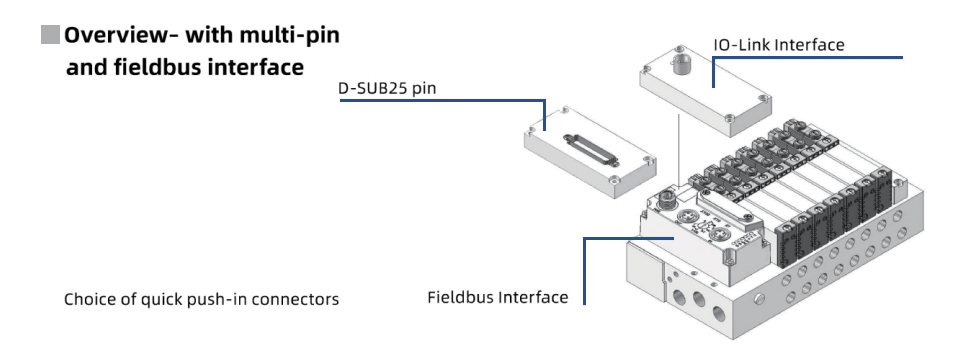

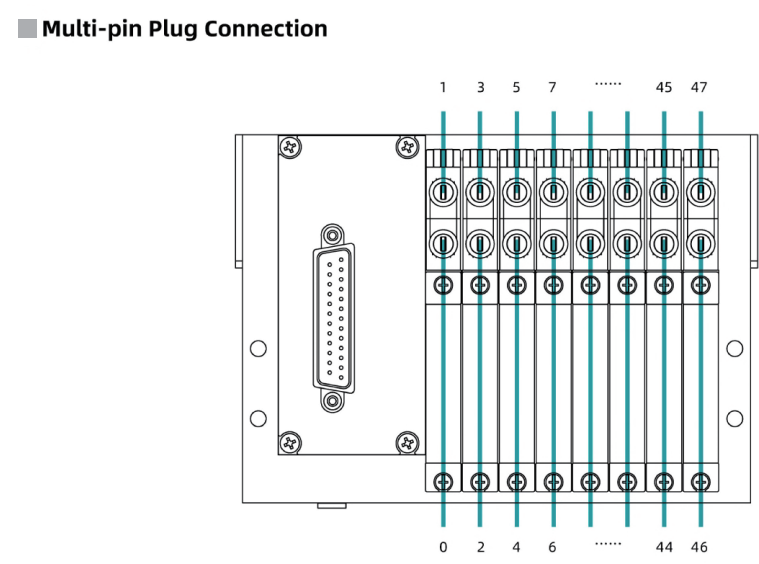

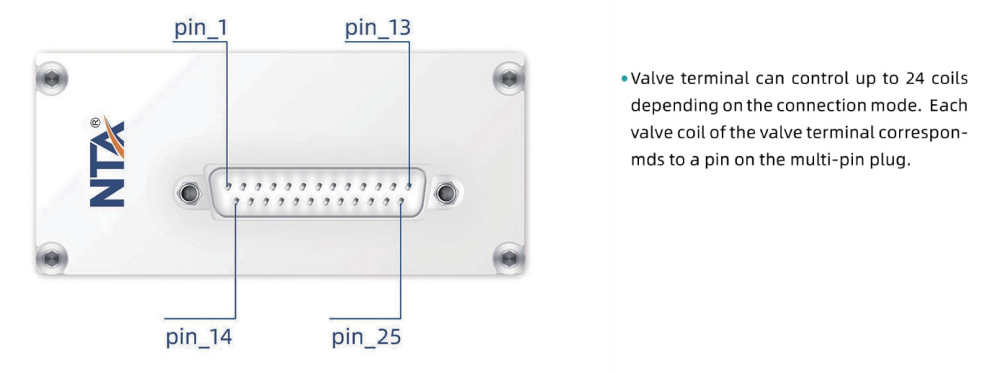

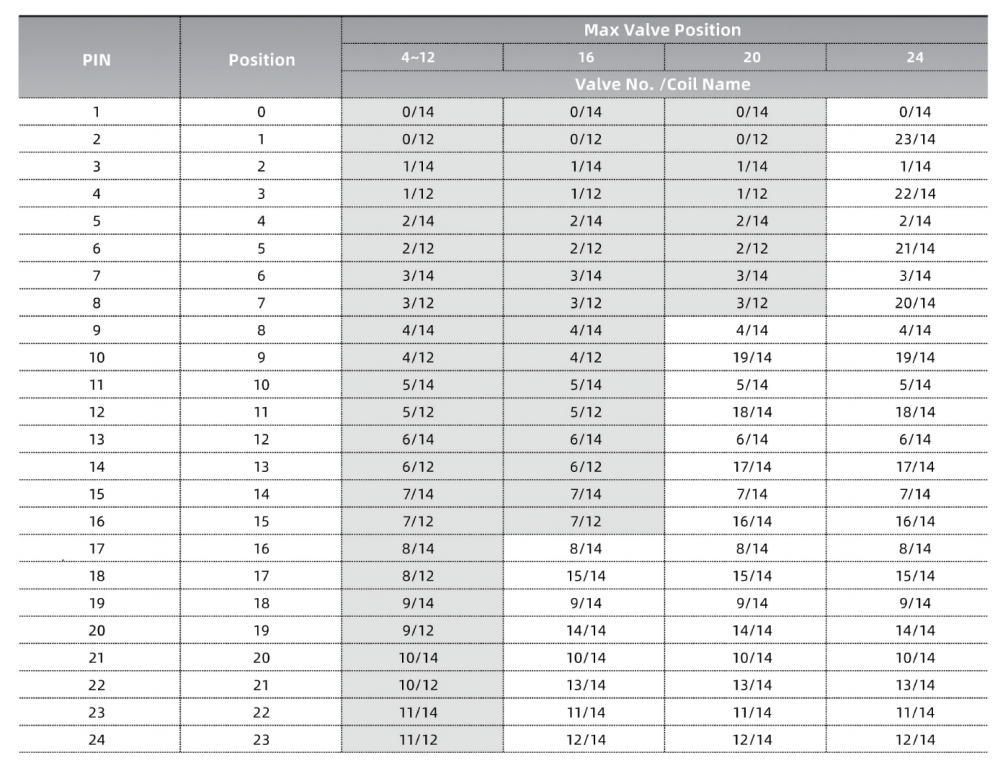

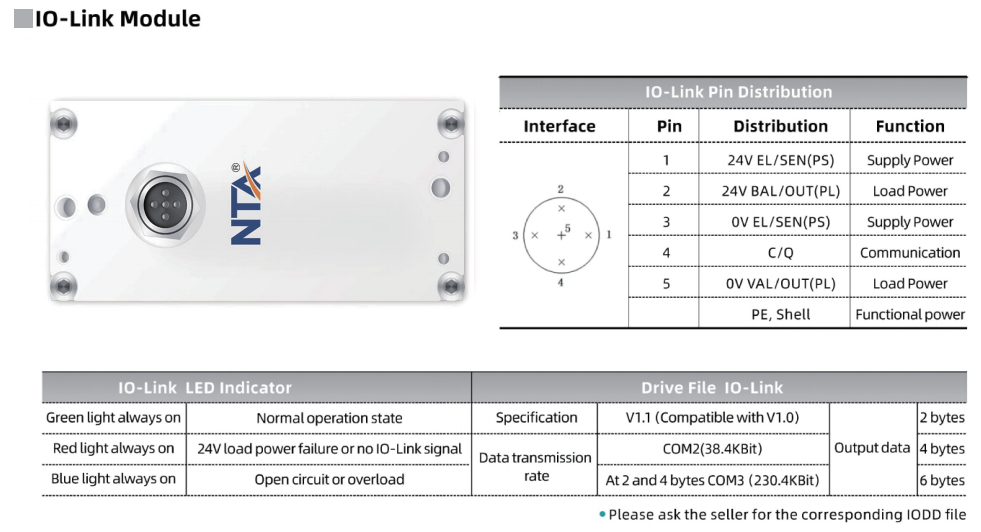

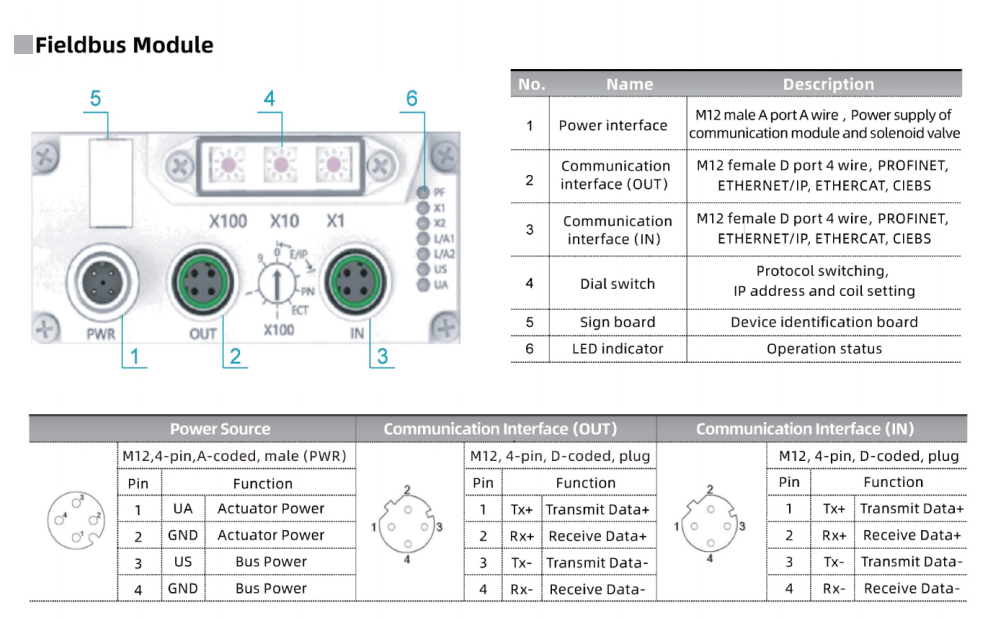

NTA valve terminals offer flexible connectivity options including 25-pin, IO-Link, and Fieldbus interfaces, enabling seamless integration, stable communication, and improved productivity throughout automated operations.

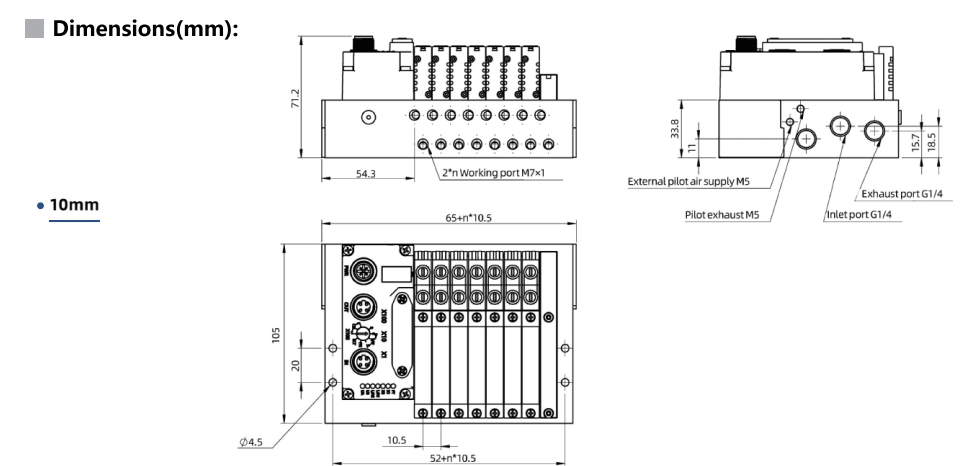

NTA valve terminals utilize compact 10 mm solenoid valves designed for maximum flow efficiency within limited installation spaces. Their refined structural design delivers rapid actuation speed and dependable performance, making them ideal for high-demand industrial automation systems.

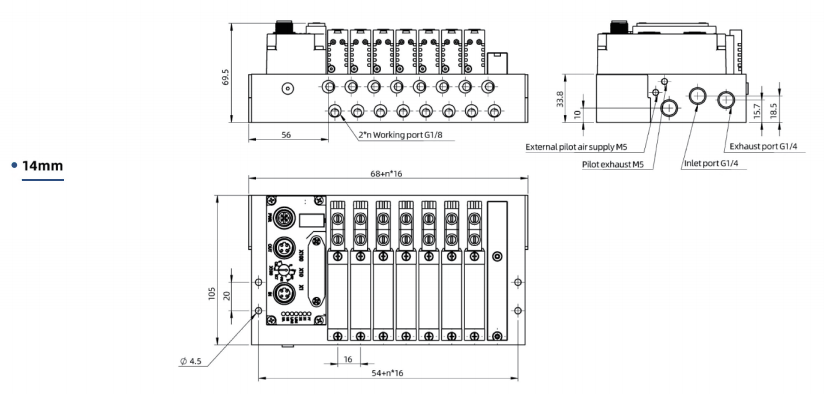

NTA valve terminals are equipped with 14 mm solenoid valves that provide superior airflow capacity and stable actuation. Engineered for heavy-duty automation environments, they offer accurate control response, long-lasting performance, and high operational efficiency throughout complex manufacturing processes.

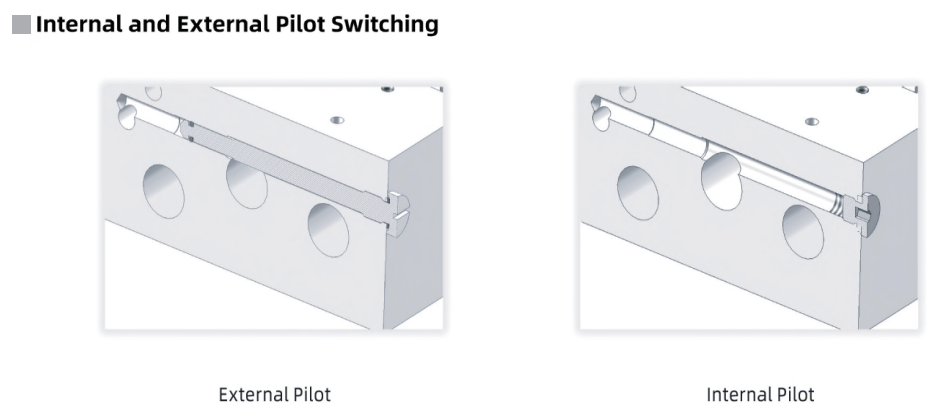

By securing a screw in the pilot port, the valve is adjusted for external pilot control, directing pilot air through the M5 threaded interface located on the base plate. When an M5 plug is applied, the configuration switches to internal pilot operation, utilizing pilot air directly from the main supply channel.

Equipped with IO-Link technology, NTA valve terminals enable continuous monitoring and efficient configuration of operating parameters. The use of standard wiring simplifies integration, enhances maintenance planning, and guarantees consistent reliability within intelligent automation networks.

Application Scenarios

NTA valve terminals are widely used across automated manufacturing lines and smart equipment:

Automated packaging systems for synchronized pneumatic control

Assembly robots requiring fast and accurate air switching

Food and beverage processing lines demanding hygienic and stable actuation

Material sorting systems that rely on quick air response and durable design

Printing and labeling equipment where compactness and reliability are critical

Their versatility makes them the preferred choice for integrated pneumatic control solutions in intelligent production lines, offering consistent performance under high-speed cycles.

Improving Production Efficiency

By integrating air and electrical connections into a single compact module, valve terminals drastically reduce wiring complexity and improve assembly efficiency. Operators can manage multiple valves through one communication line, reducing installation errors and maintenance time.

With advanced flow design and fast switching, NTA valve terminals enhance pneumatic response, ensuring smooth operation across various workstations. This improvement in control precision and reliability translates directly into higher productivity and reduced energy waste — the foundation of efficient pneumatic valve control assemblies built for Industry 4.0 automation.

Quality and Reliability

NTA operates under a strict quality management system, ensuring consistent performance and long service life for every valve terminal produced. From precision machining to pressure testing, each unit undergoes multiple inspection stages to guarantee flawless performance.

Strict in-house testing for flow rate and leak-proof reliability

High-grade materials resistant to corrosion and wear

Stable performance under continuous high-cycle operation

Reliable global supply chain and responsive technical support

This commitment to excellence ensures that NTA products maintain superior durability and long-term stability — the hallmark of precision-engineered pneumatic manifold blocks for automation systems.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.