Double solenoid Valve Terminals NTA014 For automatic industry

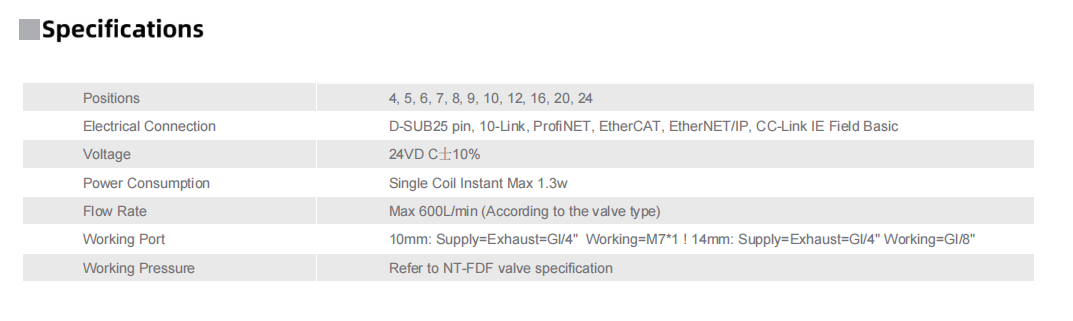

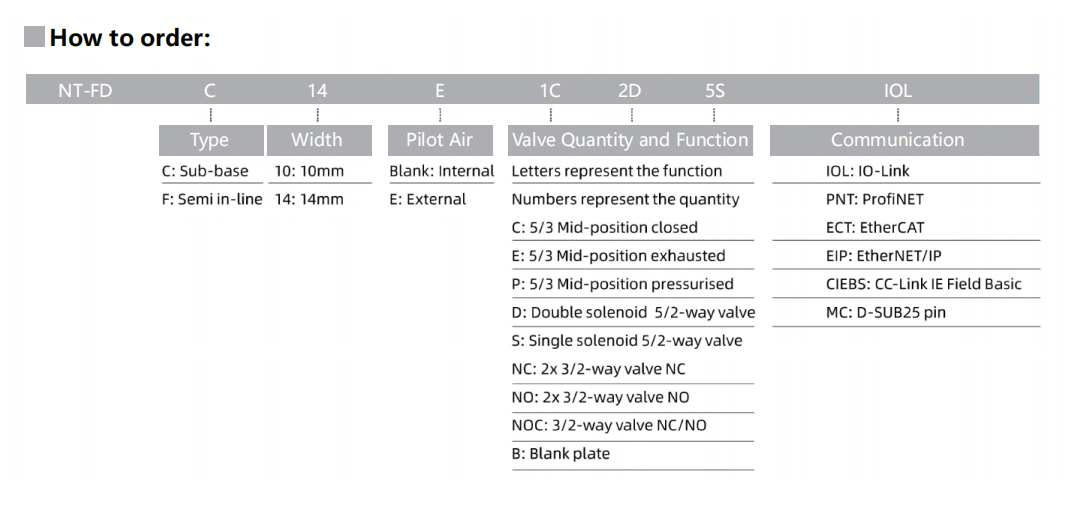

5 Way 2 Position Solenoid Valve NTA014 Series is a compact pneumatic control device, mainly used in automated production lines, industrial robots, precision machinery, packaging equipment, automobile manufacturing, electronic assembly, medical equipment, food processing, and other industrial fields. It integrates a variety of pneumatic control functions, such as solenoid valves, positioners, pressure switches Sensors, etc., reduces the number of components, and simplifies the layout. With modular design, users can add or replace modules according to their needs. Our valve island and valve plates can replace SMC products. Our Heavy Duty Connector, Sensor and Actuator are all-star products that need to be sold by our company. It can replace big brands such as Murr, Turck, etc.

Product Features

NTA valve terminals integrate several solenoid valves into one compact base, minimizing the need for complex wiring and multiple fittings. Each unit is built with corrosion-resistant materials and precision machining to ensure long service life.

Key features include

Compact modular structure for space-saving installations

Quick-connect interface compatible with diverse pneumatic setups

Optimized air passage for stable pressure distribution

High-speed response supporting fast automation cycles

Long operational durability under continuous working conditions

These features make NTA valve terminals an ideal solution for industries seeking to balance performance and reliability in pneumatic valve integration systems.

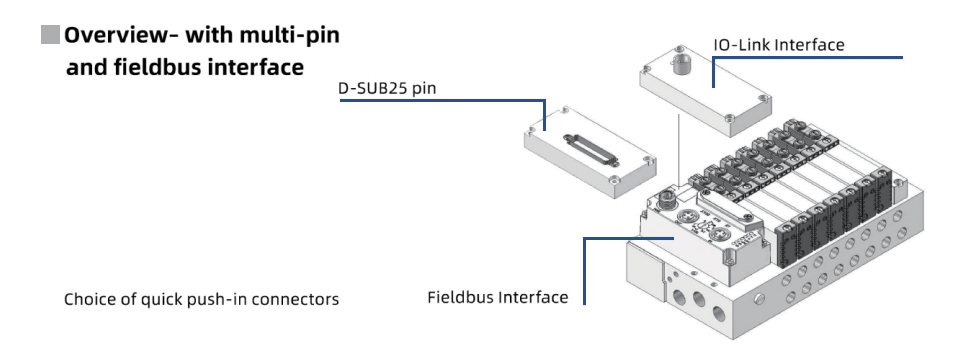

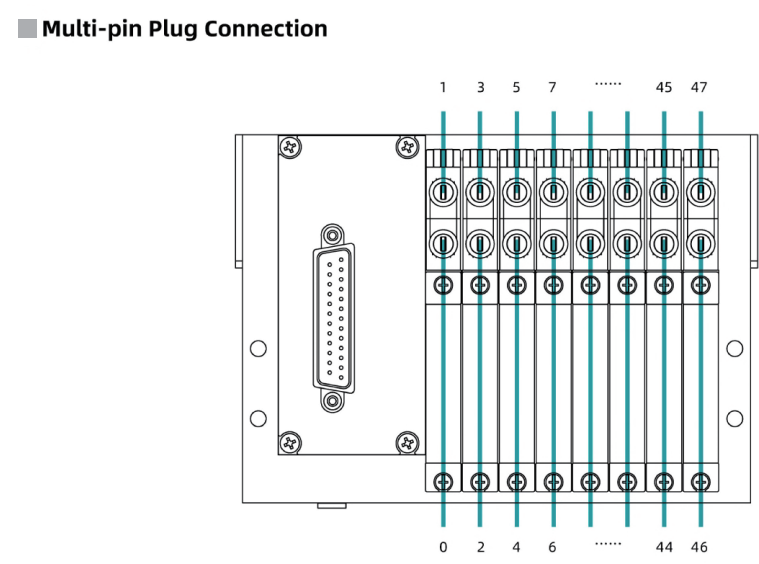

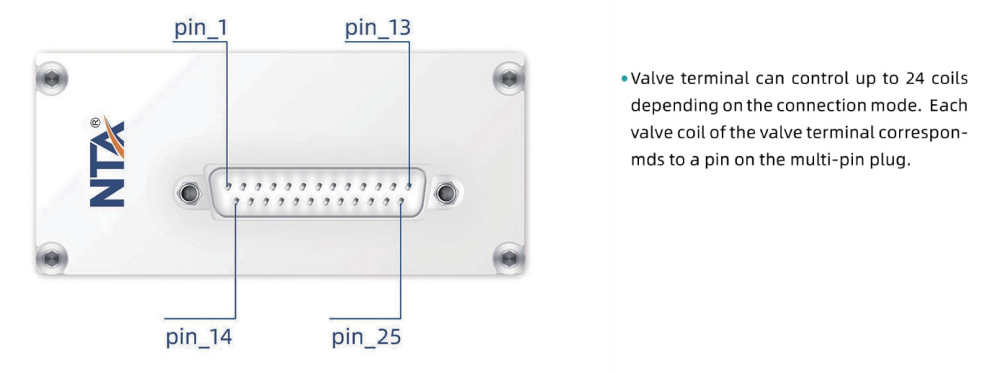

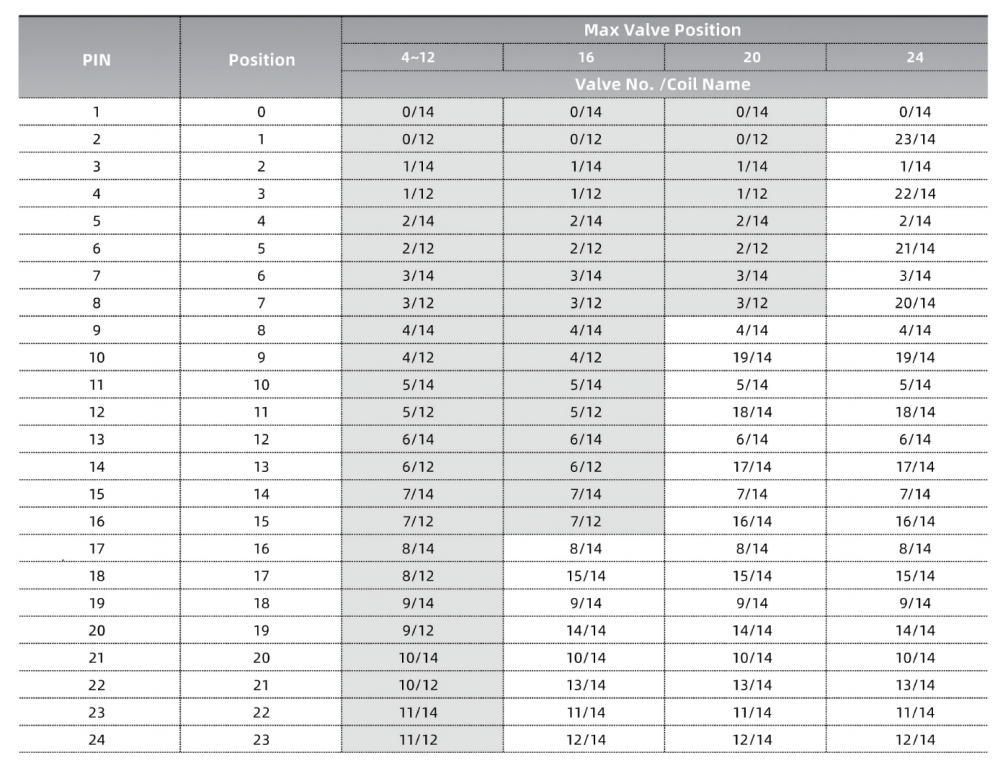

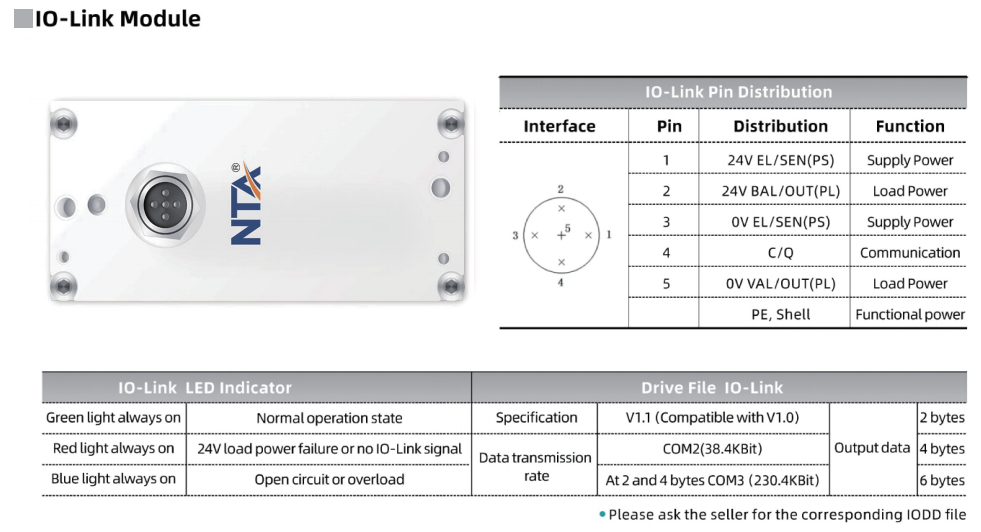

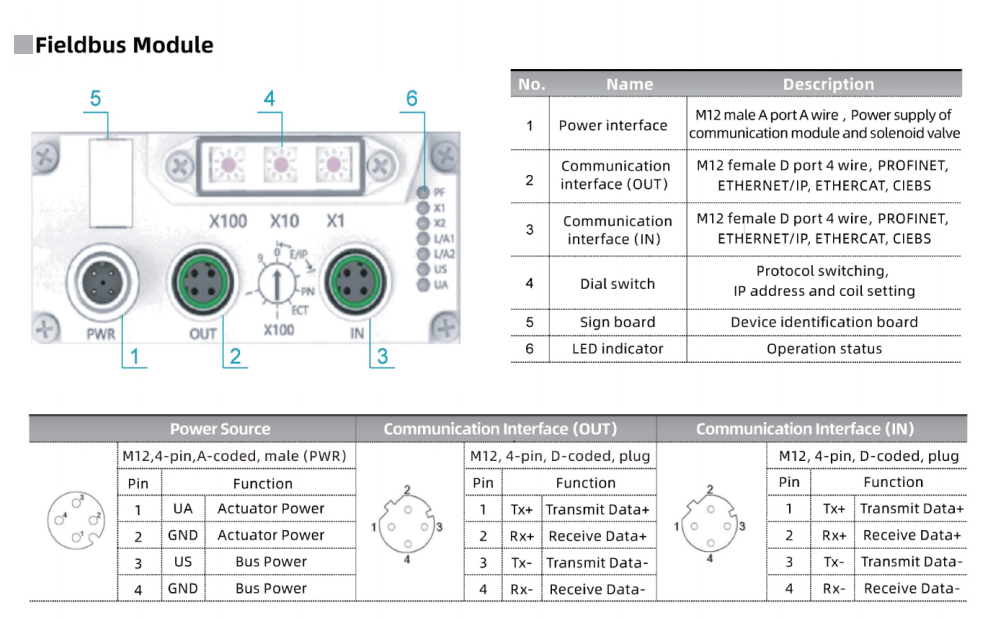

NTA valve terminals are compatible with various communication protocols such as 25-pin, IO-Link, and Fieldbus, ensuring seamless system connectivity, reliable signal transmission, and enhanced productivity throughout automated production environments.

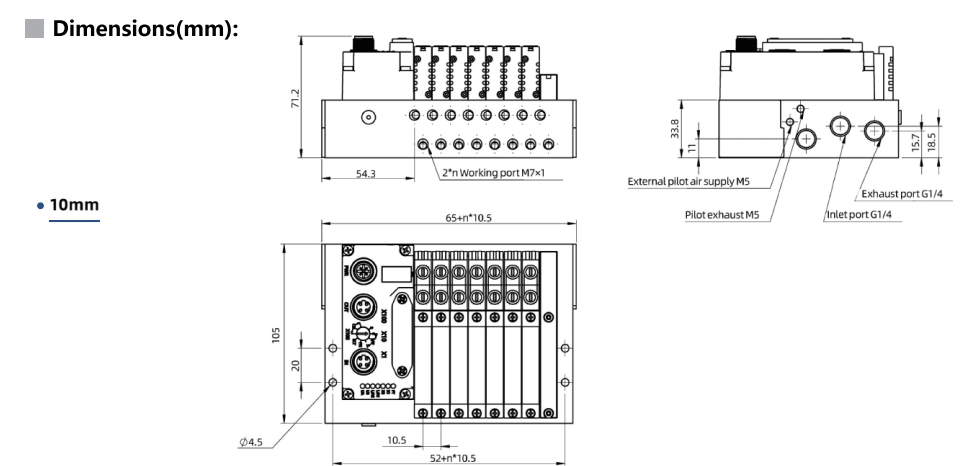

NTA valve terminals incorporate 10 mm solenoid valves configured in a space-optimized layout that maximizes flow efficiency while conserving installation space. The precise engineering of each unit ensures quick actuation and consistent reliability, even in high-duty automation applications.

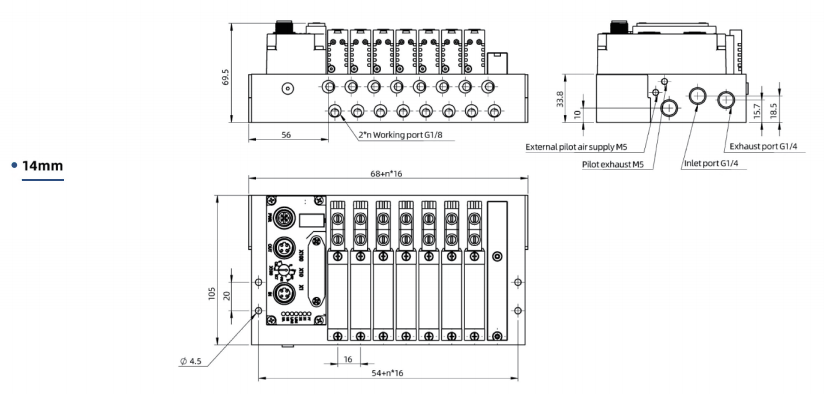

NTA valve terminals integrate 14 mm solenoid valves engineered for superior airflow dynamics and dependable switching performance. Designed to meet the rigorous demands of modern automation, they ensure precise motion control, long service life, and energy-efficient functionality across complex manufacturing environments.

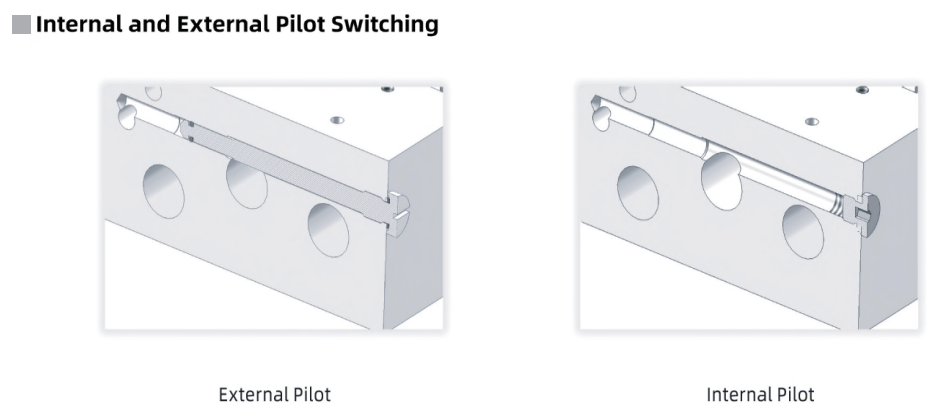

By installing a screw into the pilot port, the valve is set to operate in external pilot mode, channeling control air through the M5 threaded connection on the base plate. When the screw is replaced with an M5 sealing plug, the configuration shifts to internal pilot mode, drawing the control air directly from the system’s primary inlet source.

NTA valve terminals equipped with IO-Link modules allow continuous monitoring of system status and straightforward parameter configuration. Using standard cabling, they simplify integration, facilitate predictive maintenance, and deliver reliable performance across advanced automated systems.

Application Scenarios

Valve terminals are essential across a wide range of industries that depend on accurate pneumatic control.

NTA products are widely used in:

Packaging equipment for synchronized motion control

Automotive production lines for robotic assembly systems

Food and beverage automation where hygiene and consistency matter

Electronics manufacturing for compact, precise air control setups

Logistics systems using conveyors and pick-and-place units

Their versatility ensures that NTA valve terminals provide dependable operation in automated pneumatic control networks, whether in high-speed manufacturing or precision assembly environments.

Improving Productivity and Efficiency

One of the biggest advantages of NTA valve terminals is the ability to boost productivity.

By centralizing multiple valve functions into one unit, wiring and tubing requirements are reduced significantly, shortening installation time and lowering maintenance costs.

The streamlined air flow system ensures fast response and consistent performance, minimizing downtime and optimizing energy usage. In automated production, this means higher throughput and reduced air leakage—essential for cost-efficient pneumatic automation assemblies in large-scale manufacturing.

Quality and Reliability

Every NTA valve terminal undergoes rigorous quality inspection under ISO-certified production standards.

Our facilities utilize advanced assembly automation, leakage testing, and functional validation for every valve terminal module.

With a traceable production system and precision calibration, NTA ensures stable performance and long-term dependability.

This commitment to excellence allows NTA to deliver industrial-grade valve terminal control manifolds trusted by engineers worldwide.

Why Choose NTA Valve Terminals

Stable air pressure and minimal flow loss

Consistent operation under harsh environments

Easy modular upgrades for expanding systems

Reduced assembly and service time

Backed by a strict, traceable quality assurance program

Each valve terminal is built to provide exceptional reliability while helping customers achieve sustainable automation performance through high-precision modular pneumatic distribution units.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.