Innovative Valve Terminal Solutions for Modern Automation Systems — NTA

Valve terminals are essential to achieving efficient and intelligent automation. With compact design, stable actuation, and flexible connectivity, NTA offers high-value pneumatic solutions tailored for global industries. Whether it’s packaging, automotive, robotics, or logistics, NTA’s valve terminals empower manufacturers to build smarter, faster, and more reliable automation systems.

Experience the strength of NTA pneumatic valve manifolds for advanced automation, where performance, precision, and durability converge to elevate your production line.

Product Overview

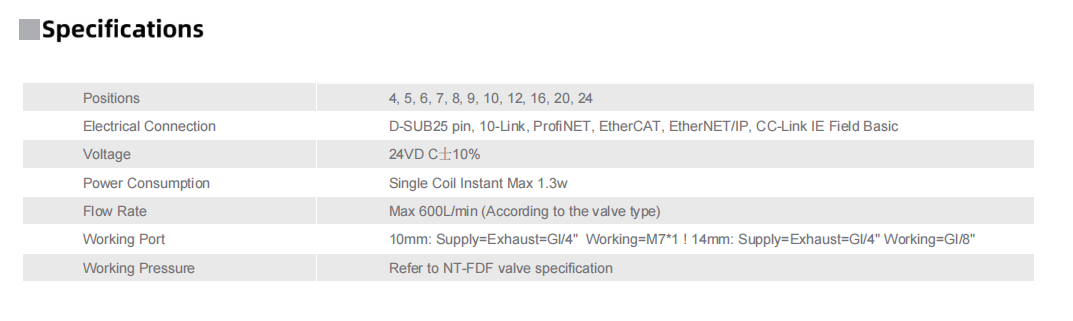

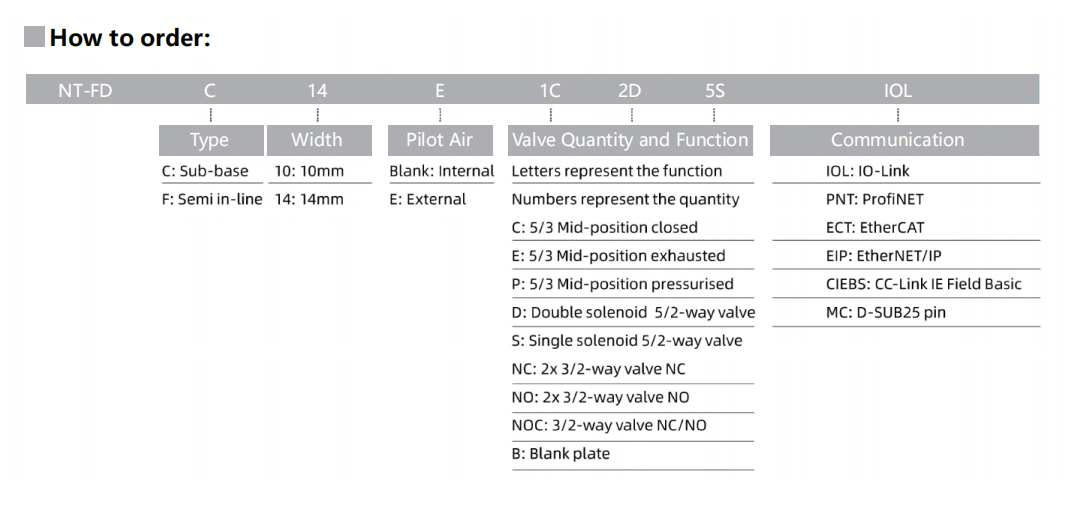

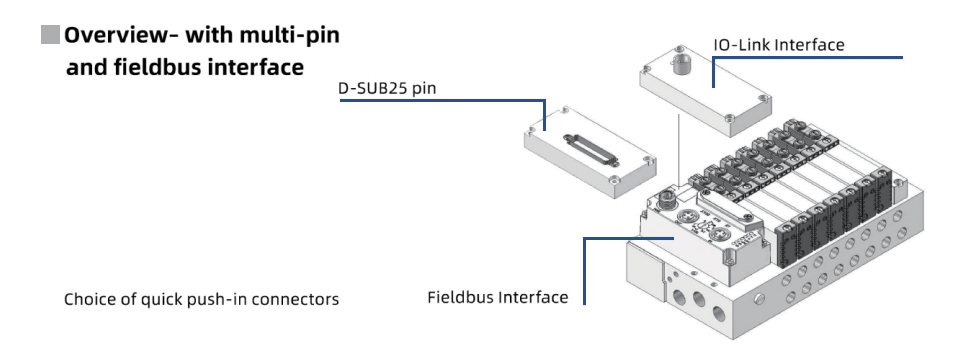

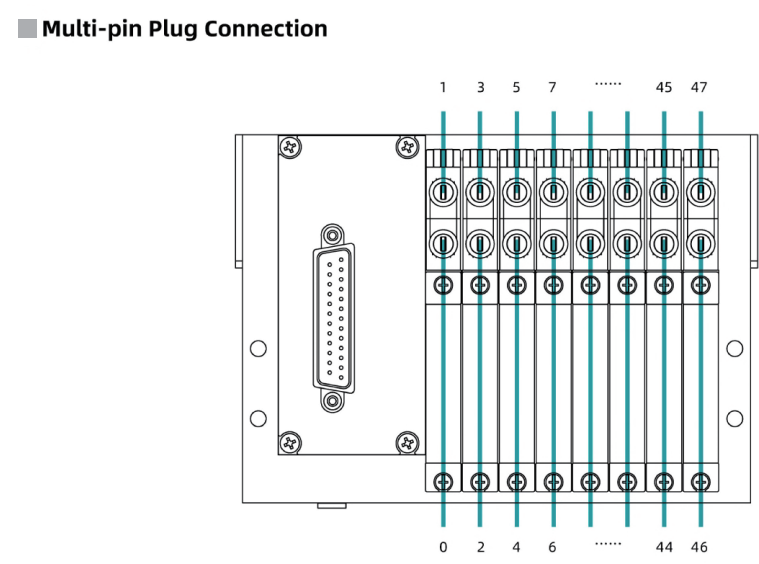

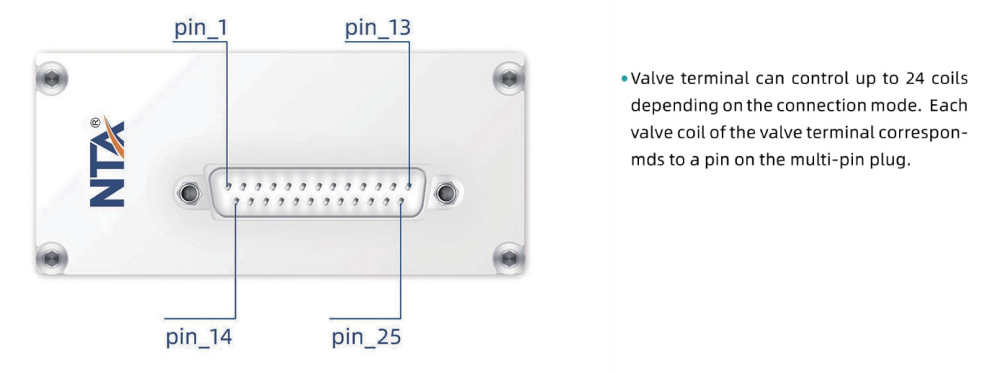

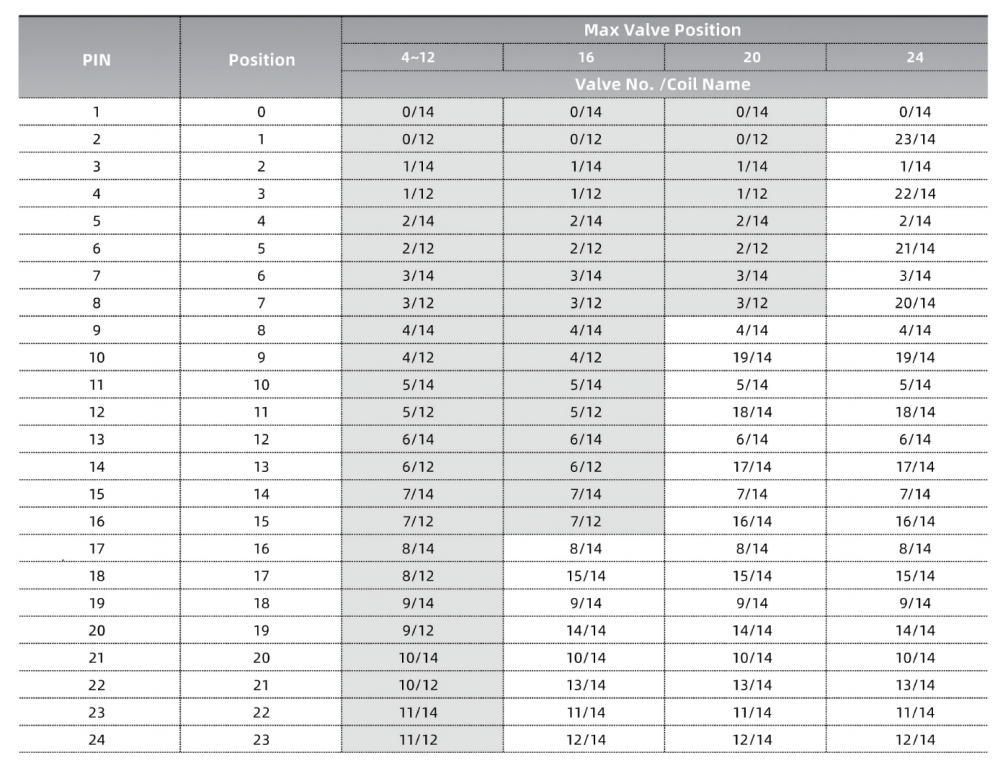

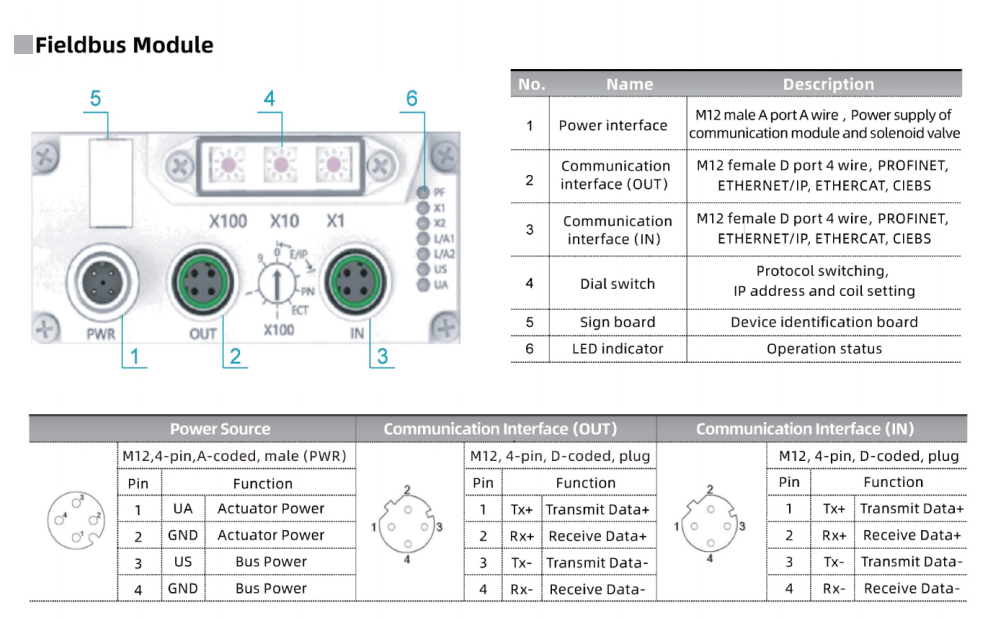

NTA valve terminals combine advanced pneumatic design with digital connectivity to meet the growing needs of automation. The units integrate multiple solenoid valves into a single compact manifold, minimizing space while maintaining powerful airflow and stable actuation. With multiple communication interfaces, including Fieldbus, IO-Link, and 25-pin connections, they allow seamless integration with various control architectures.

Designed for flexible system expansion and efficient performance, these valve terminals represent the next generation of high-precision pneumatic control assemblies built for smart production environments.

Key Product Features

Modular configuration for easy customization and scalability

Optimized air passages ensuring fast response and reduced pressure loss

Multiple connectivity standards for diverse automation networks

Durable aluminum alloy body for long-term stability under high cycle operations

Integrated monitoring options to simplify maintenance and diagnostics

Each feature reflects NTA’s commitment to delivering advanced industrial pneumatic distribution manifolds that perform reliably even under demanding conditions.

NTA valve terminals offer 25-pin, IO-Link, and Fieldbus communication options, enabling seamless integration, stable signal communication, and improved operational efficiency within modern automation systems.

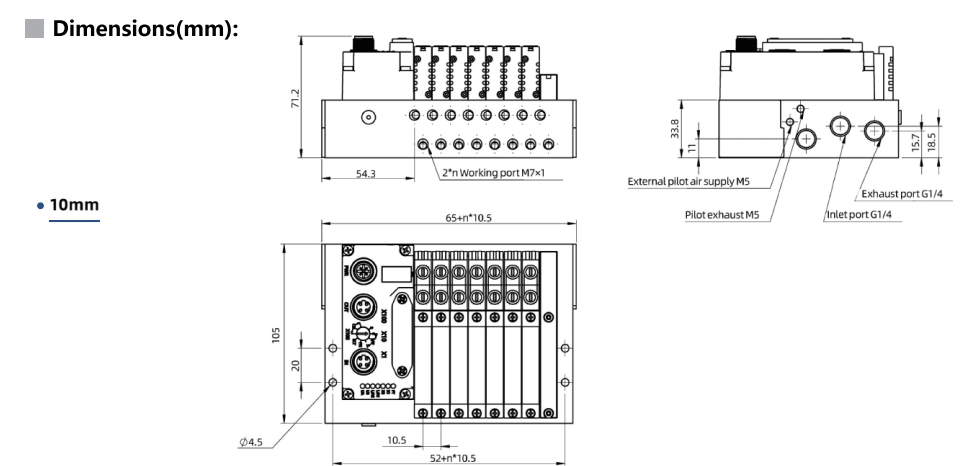

NTA valve terminals utilize 10 mm solenoid valves in a compact and efficient structure, delivering superior flow performance while reducing installation space. The optimized layout ensures fast actuation and consistent reliability under high-demand automation conditions.

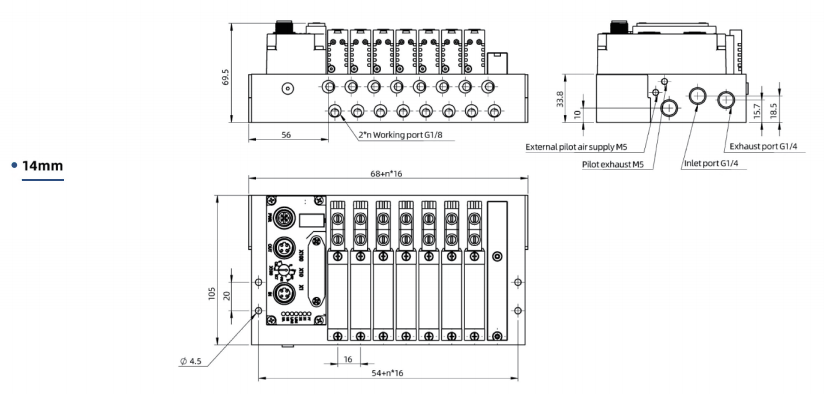

NTA valve terminals integrate 14 mm solenoid valves engineered for superior flow capacity and consistent actuation. Designed to meet the needs of high-performance automation, they provide accurate control, long-term reliability, and optimized efficiency in complex manufacturing systems.

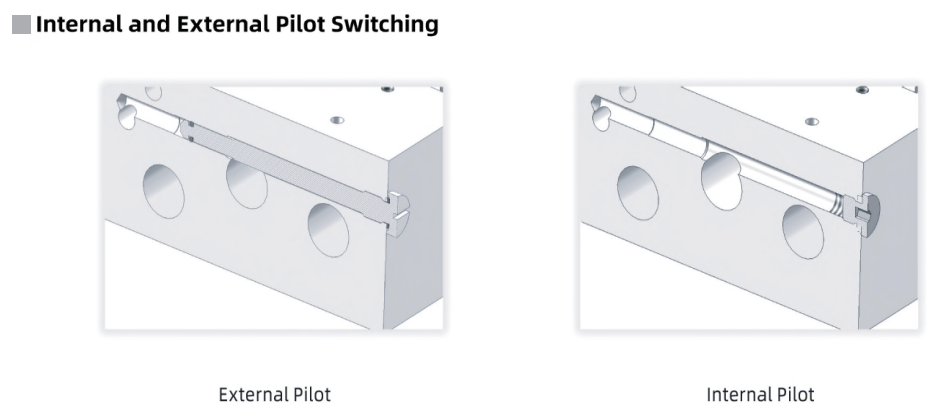

When a screw is installed in the pilot port, the valve operates in external pilot mode, with pilot air delivered through the M5 threaded connection on the base plate. Fitting an M5 plug switches the valve to internal pilot mode, allowing pilot air to be drawn directly from the main air supply.

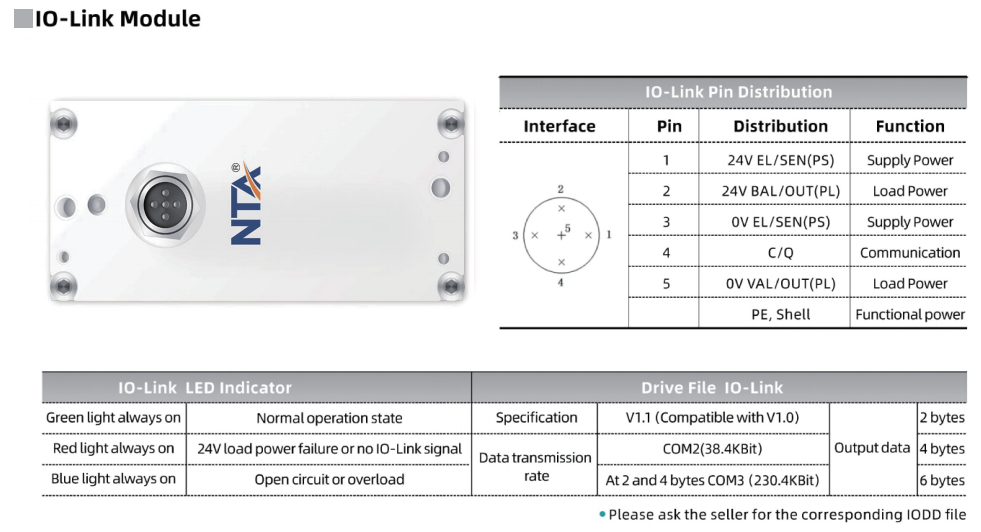

NTA valve terminals featuring built-in IO-Link modules enable real-time monitoring and convenient parameter configuration. Using standard cabling, they simplify wiring, enhance predictive maintenance capabilities, and deliver consistent, high-reliability performance in intelligent automation systems.

Application Scenarios

NTA valve terminals are used widely across automation systems that require compact layout and precise air control:

Automated packaging and labeling machines for synchronized motion control

Robotic handling units for high-speed pick-and-place operations

Automotive assembly lines where rapid, coordinated actuation is essential

Electronics and semiconductor processes that demand clean and compact pneumatic solutions

Material conveying systems requiring steady performance and low maintenance

Their versatility makes them the preferred choice for multi-channel pneumatic control modules in smart manufacturing, where system performance and reliability are key.

How Valve Terminals Improve Production Efficiency

NTA valve terminals help manufacturers reduce wiring complexity and simplify maintenance by centralizing pneumatic and electrical connections. This integration cuts installation time and improves overall workflow efficiency.

Their rapid switching performance, modular expansion capability, and stable air control reduce downtime and energy waste. By optimizing airflow and minimizing pressure drops, these systems ensure maximum output in minimal space — the foundation of energy-efficient pneumatic valve integration systems designed for productivity-driven industries.

Why Choose NTA

NTA upholds strict international quality standards through a comprehensive quality management system that covers design, production, and testing. Every valve terminal undergoes performance verification to guarantee consistency and reliability.

Precision manufacturing with advanced CNC machining

Rigorous quality inspection from raw materials to final assembly

Strong customization capability for industry-specific applications

Responsive global service to support fast delivery and technical assistance

This ensures that every NTA valve terminal serves as a dependable component within next-generation modular pneumatic automation units, driving stable operation and long-term system performance.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.