Enhance Automation Efficiency and Reliability with Advanced Valve Terminals for Industrial Applications | NTA

NTA valve terminals deliver efficiency, flexibility, and reliability. With advanced design, multiple interfaces, and strict quality standards, NTA provides a trusted modular fieldbus valve terminal for smart factories to drive smarter automation worldwide.

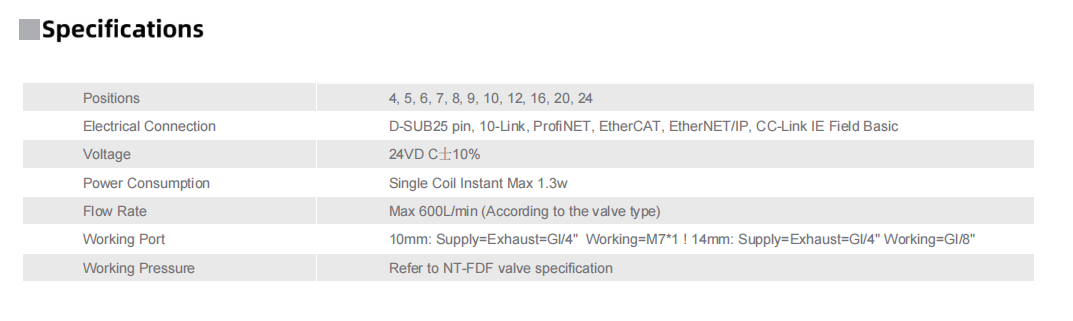

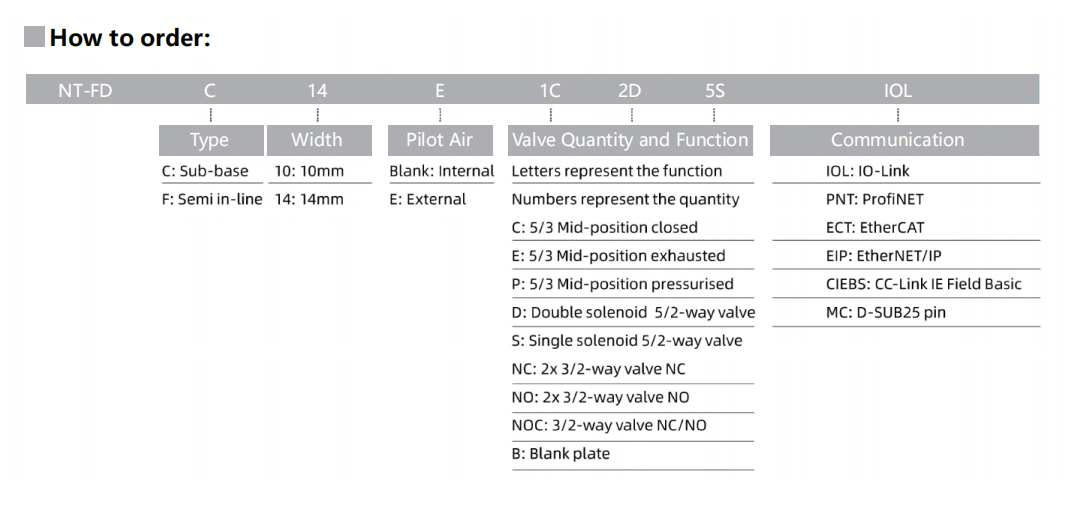

Compact & Modular Design – Space-saving and easy to expand.

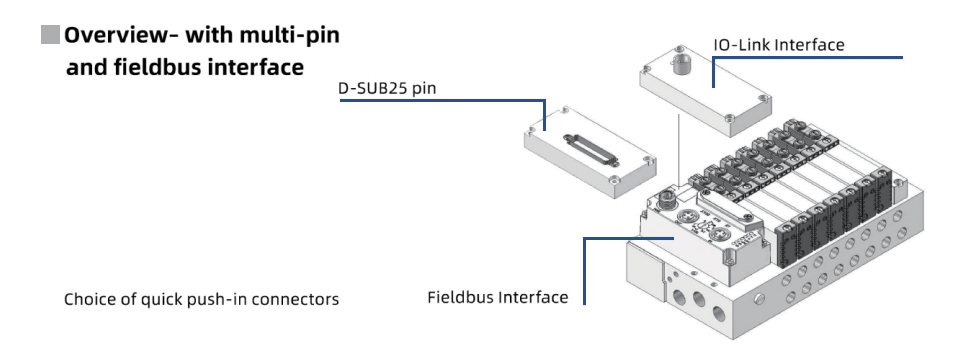

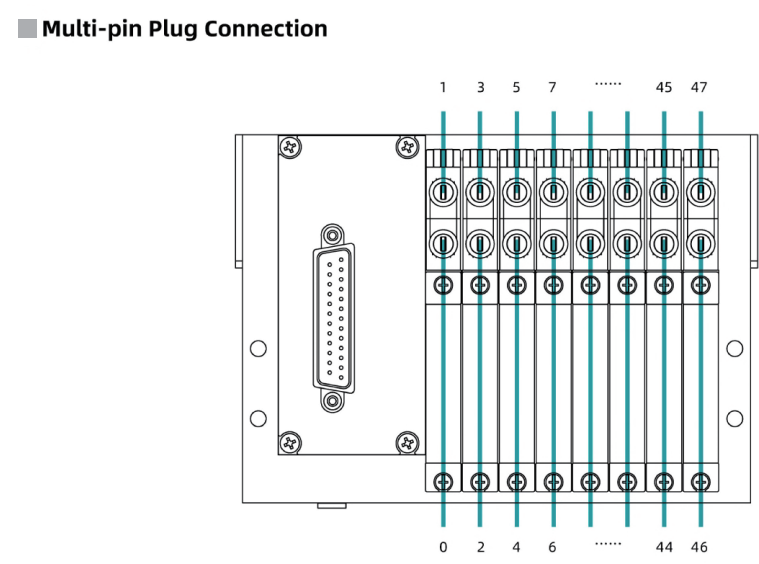

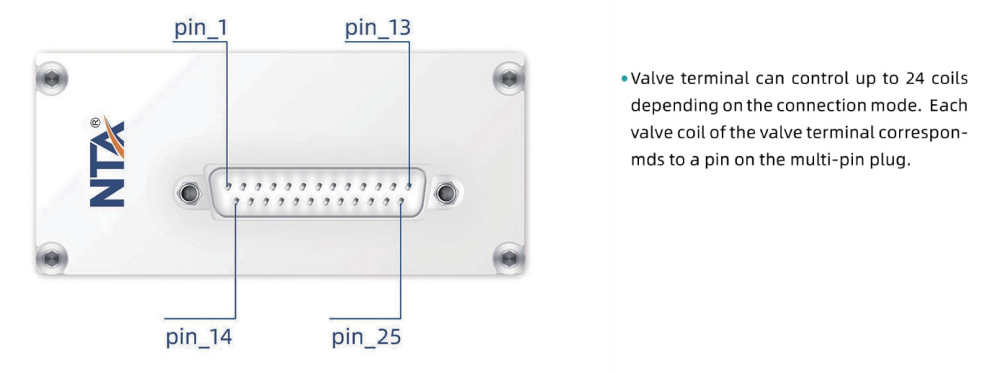

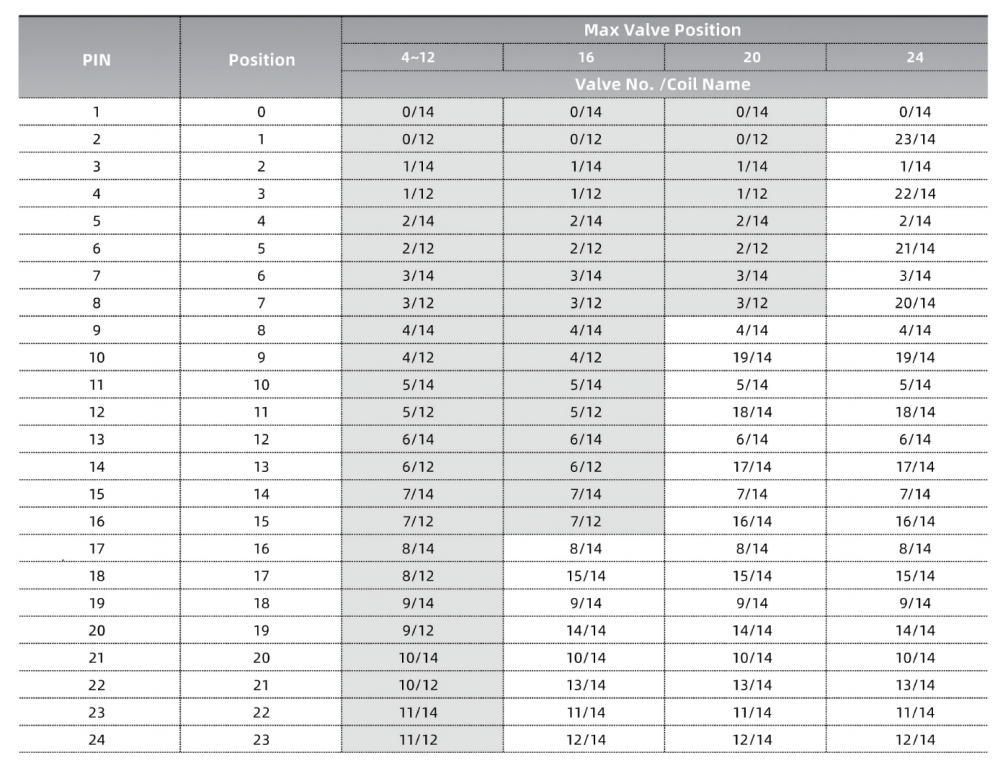

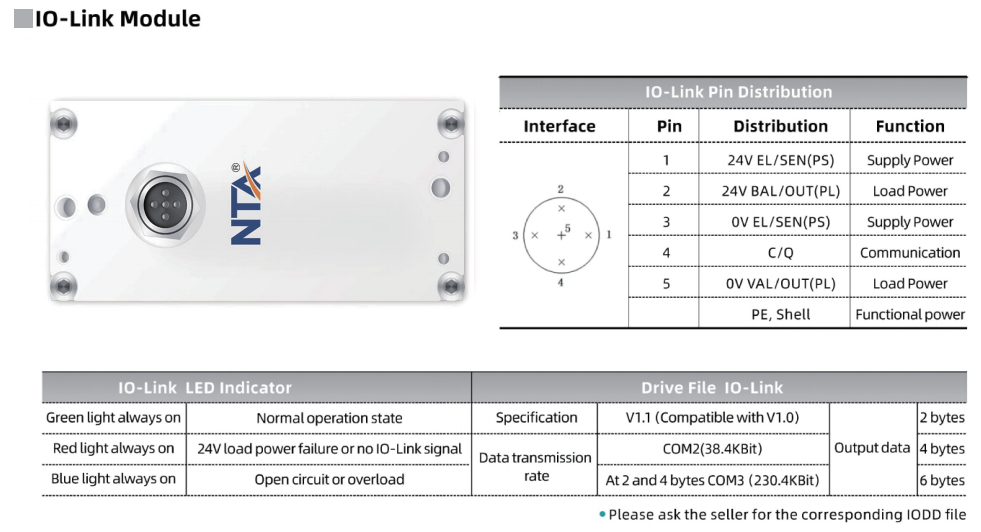

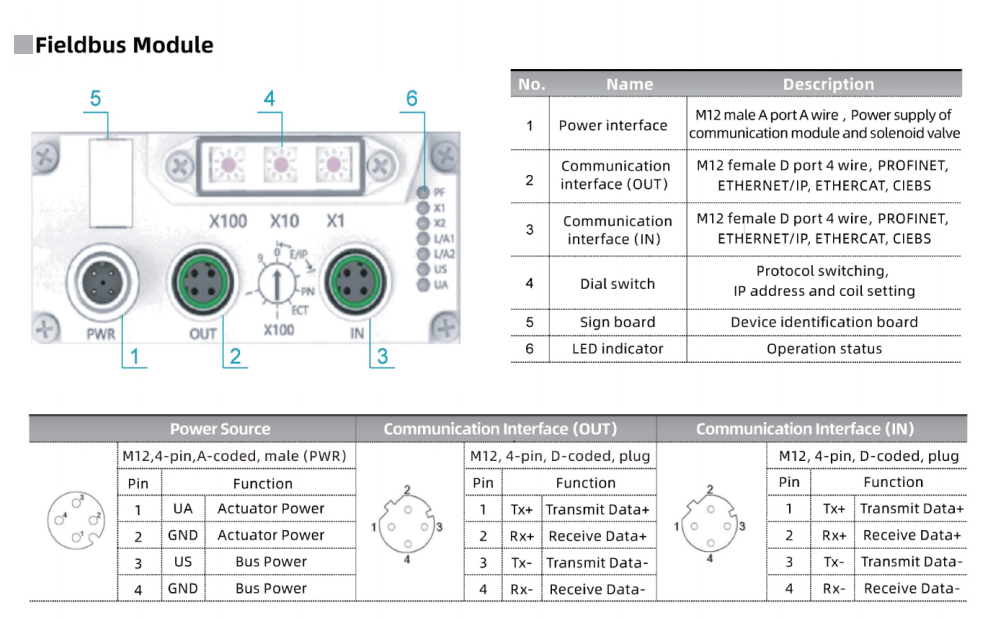

Flexible Interfaces – 25-pin, IO-Link, and Fieldbus for seamless integration.

High-Performance Valves – Efficient 10mm and 14mm solenoid options.

Easy Maintenance – Simplified wiring and reduced downtime.

NTA valve terminals feature 25-pin, IO-Link, and Fieldbus interfaces for seamless integration, reliable communication, and enhanced automation efficiency.

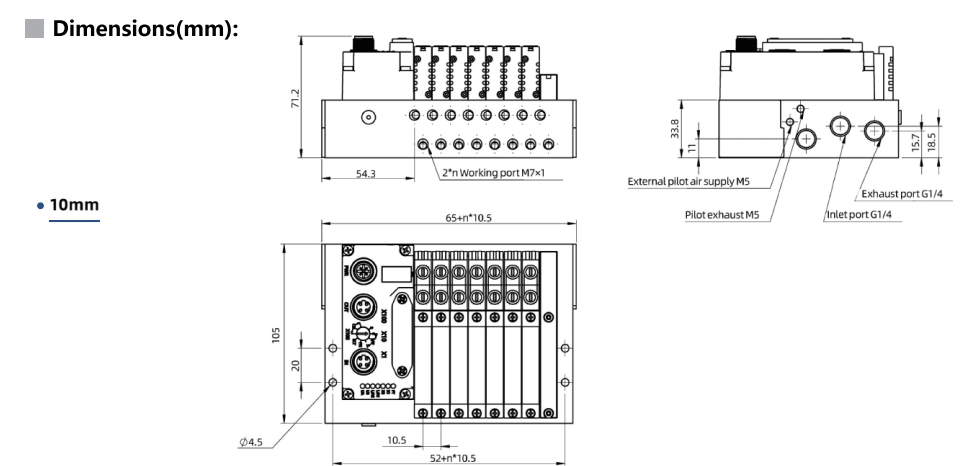

NTA valve terminals utilize 10mm solenoid valves arranged in a space-efficient design, providing high flow rates while minimizing installation footprint. This compact configuration ensures rapid response and reliable operation in demanding automation systems.

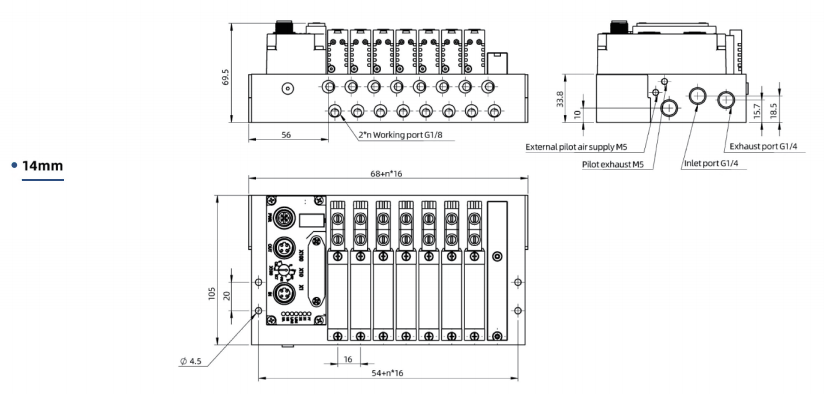

NTA valve terminals are equipped with 14mm solenoid valves, delivering higher flow capacity and stable switching. Ideal for demanding applications, they ensure reliable control, durability, and efficient operation in automated systems.

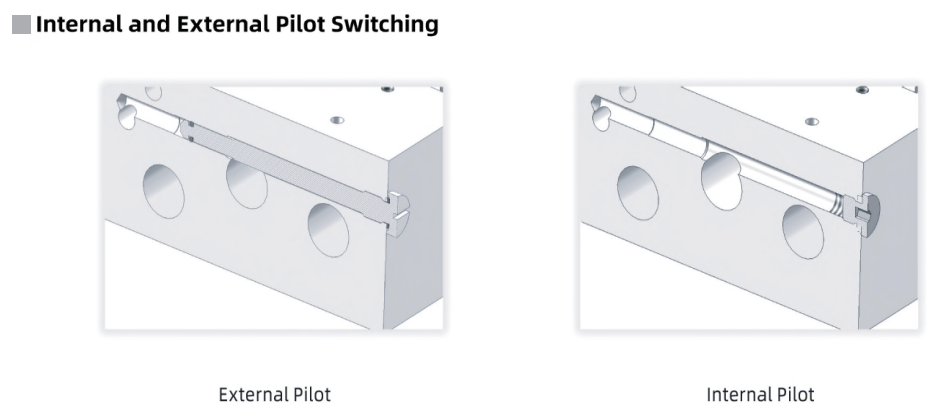

Installing a screw in the pilot port configures the valve for external pilot mode, directing pilot air via the M5 thread on the base plate. Using an M5 plug switches the valve to internal pilot mode, sourcing pilot air directly from the main inlet.

NTA valve terminals with IO-Link modules allow real-time system monitoring and easy parameter configuration. Standard cabling simplifies setup, supports predictive maintenance, and ensures dependable performance in smart automation environments.

Application Scenarios

Widely applied in packaging, automotive production, logistics, and electronics assembly, NTA valve terminals are ideal for high-performance modular valve islands used in robotic handling, conveyor systems, and synchronized automation processes.Improved Productivity

By centralizing functions, valve terminals save installation time, reduce maintenance, and increase uptime. Users benefit from a scalable IO-Link valve terminal manufacturer China solution that supports future system upgrades with ease.

Why Choose NTA

Proven pneumatic expertise

Strict quality control

Customization options

Global logistics and service

Reliable long-term performance

Application Scenarios

NTA valve terminals are widely adopted in packaging, automotive, logistics, robotics, and electronics manufacturing. They are particularly effective in automated assembly line valve solution setups, where synchronized control of multiple actuators is essential.

For example:

In packaging systems, valve terminals regulate high-speed conveyors and sorting equipment.

In automotive assembly, they enable precise robotic handling, welding, and clamping operations.

In logistics, they support the automation of distribution centers with reliable flow and switching control.

In electronics, they drive lightweight, compact assembly lines requiring both precision and efficiency.

By implementing NTA solutions, factories reduce downtime, optimize cycle times, and enhance overall equipment effectiveness.

Driving Efficiency in Automation

One of the standout benefits of NTA valve terminals is their ability to streamline installation. With simplified wiring and standard cabling, setup time is significantly reduced. Integrated diagnostics make predictive maintenance possible, allowing operators to detect potential issues before they escalate. This reduces unexpected stoppages and ensures continuous productivity.

Moreover, the design of NTA valve terminals minimizes air consumption, supporting sustainability and lowering operating costs. By reducing energy waste, they contribute to greener production processes, making them an ideal choice for companies seeking energy-efficient pneumatic valve terminals.

Advantages of Choosing NTA

NTA operates under a strict quality management system, ensuring that every valve terminal meets international standards and delivers long-term dependability. Customers benefit from:

Consistent reliability even in demanding environments

Enhanced flexibility with modular, scalable options

Cost-effective installation with reduced cabling requirements

Sustainability through optimized air and energy usage

When integrated into high-performance modular valve island systems, NTA products offer an unbeatable balance of durability, performance, and efficiency.

Building Smarter Factories

The future of industrial automation is moving toward fully connected, intelligent systems. NTA supports this vision with valve terminals designed for digital integration and data-driven performance. By offering a trusted smart factory valve automation system, NTA empowers manufacturers to operate more intelligently—achieving greater flexibility, reliability, and scalability.

Whether it’s a single production line or a fully automated factory, NTA valve terminals provide the foundation for long-term growth and operational success.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.