High-Performance Valve Terminals with Modular Design and IO-Link Integration — NTA

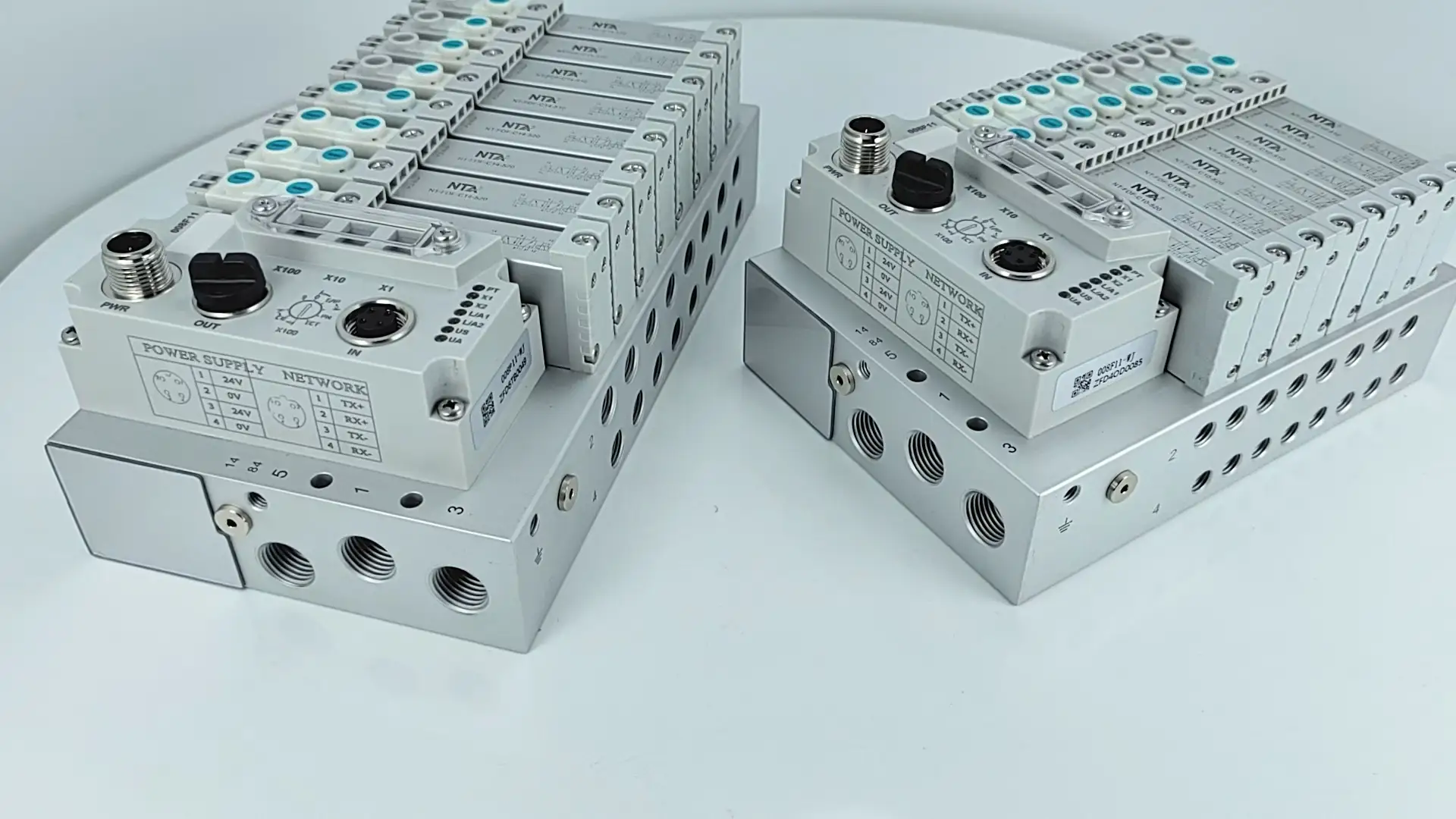

NTA valve terminals are widely used in packaging lines, robotics, assembly systems, conveyors, and process equipment, where they simplify pneumatic distribution and improve efficiency.

As a modular pneumatic valve terminal supplier, NTA delivers reliable products tailored for automation needs. Whether you are looking for a valve terminal for automation systems or a trusted industrial valve terminal manufacturer, NTA ensures dependable performance and global support.

Choose NTA valve terminal solutions to optimize your production line and enhance system reliability.

Modular Structure – Supports flexible configurations with multiple valve combinations in one compact platform.

High Integration – Reduces the need for individual valve wiring and tubing, minimizing installation time.

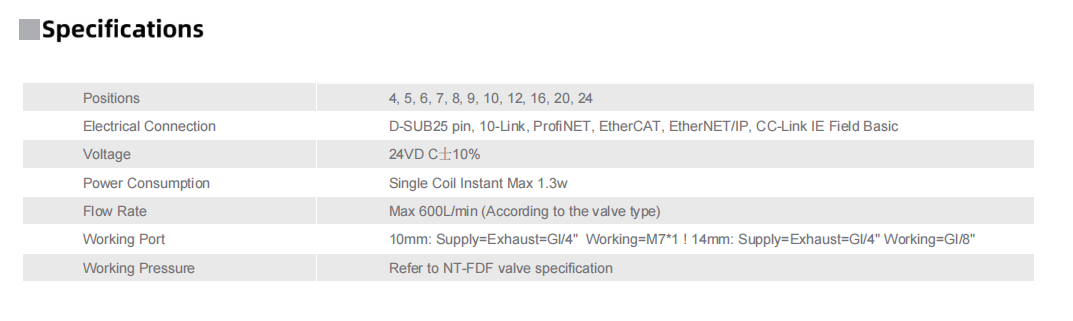

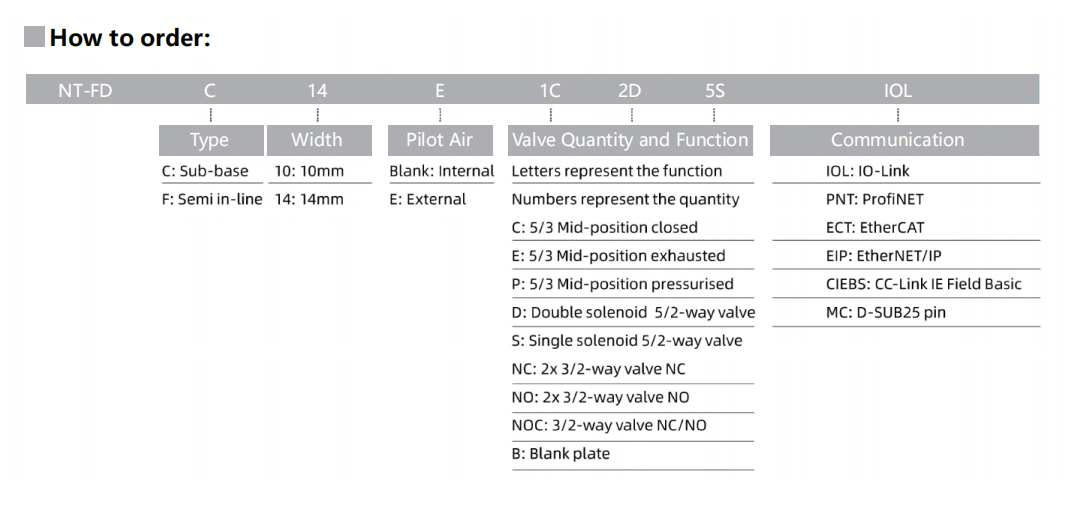

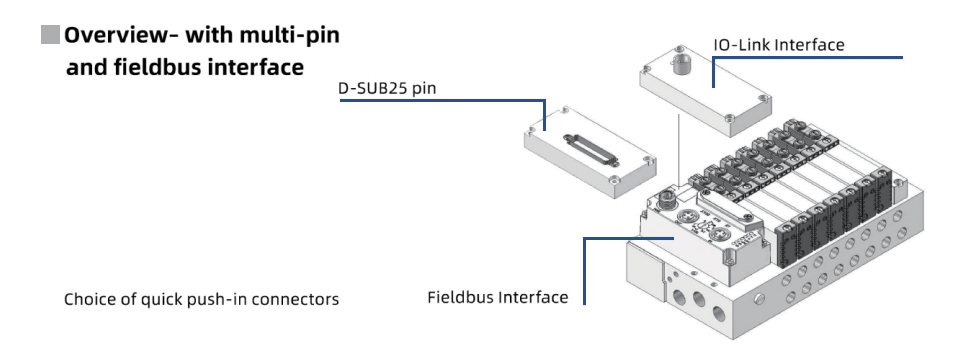

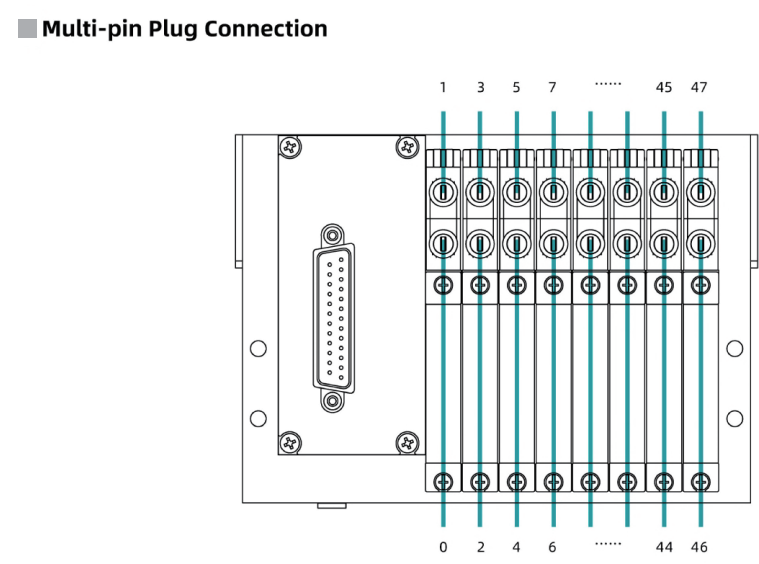

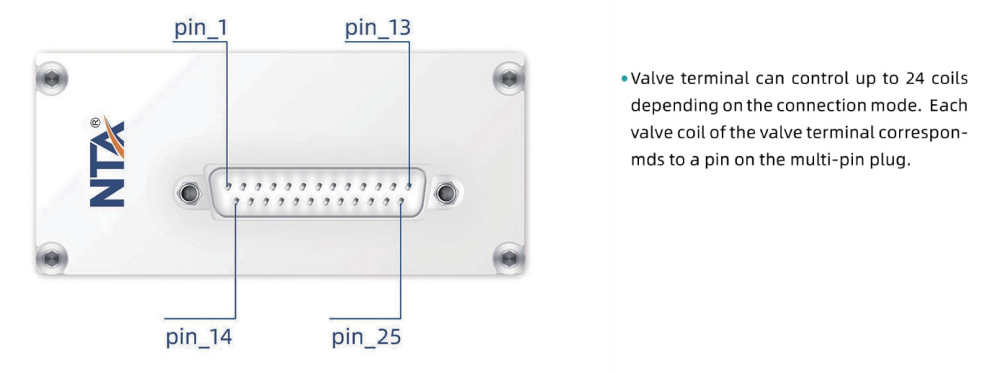

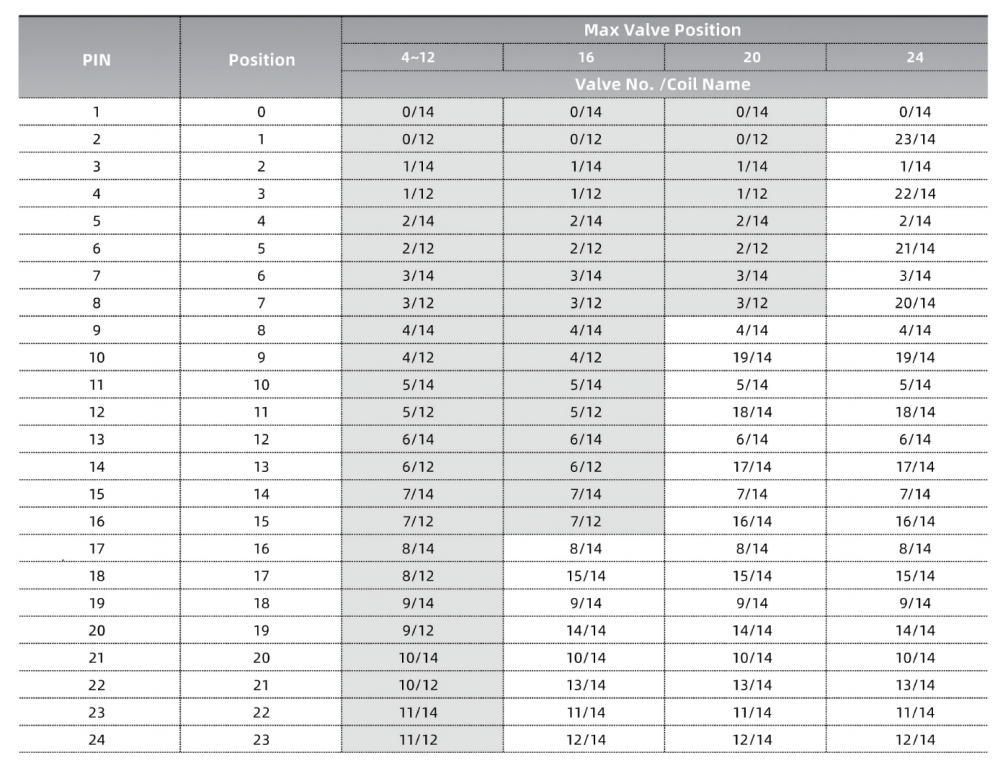

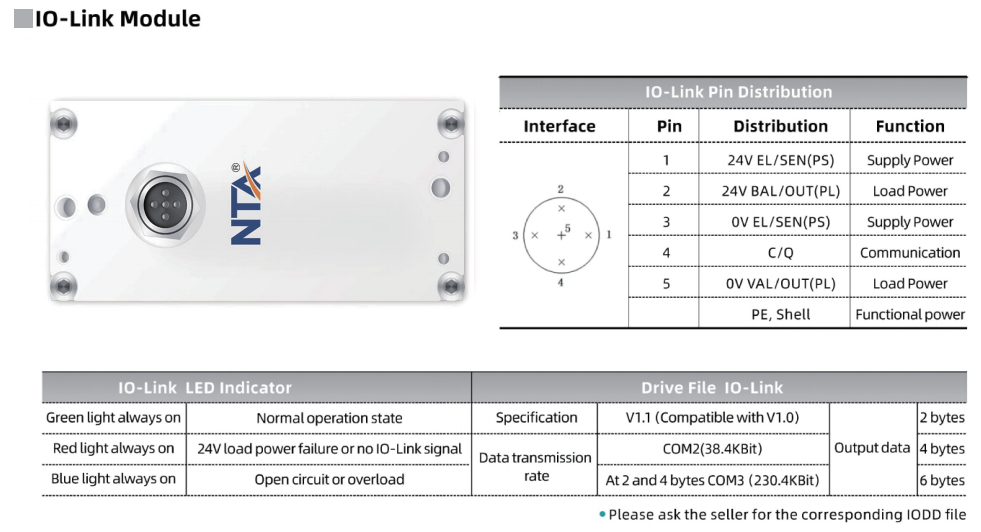

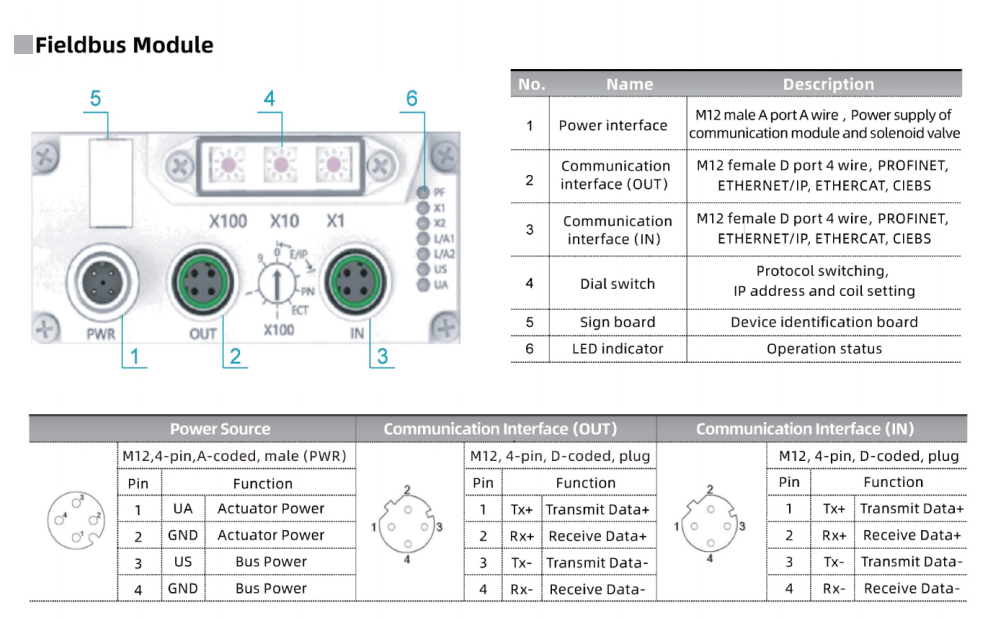

Multiple Interface Options – Compatible with D-SUB 25 pin, IO-Link modules, and Fieldbus interfaces for seamless connectivity.

Compact Design – Saves cabinet and machine space while maintaining robust air flow capacity.

Durable Construction – Built from precision-machined alloys and high-performance seals for long service life.

Sensor-Ready – Supports position feedback and system diagnostics to enable predictive maintenance.

NTA valve terminals with 25-pin, IO-Link, and Fieldbus interfaces ensure easy integration, reliable communication, and real-time diagnostics, enhancing flexibility and efficiency in automation systems.

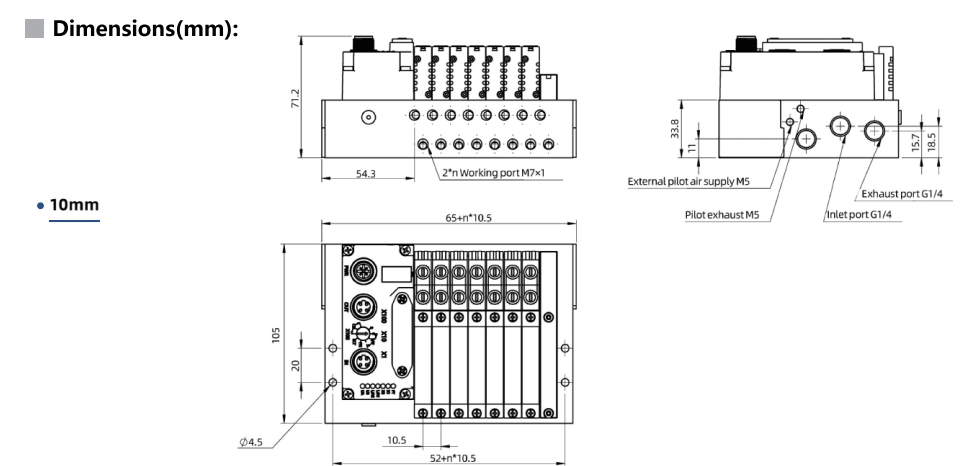

NTA valve terminals integrate 10mm solenoid valves in a compact layout, delivering strong airflow capacity within minimal space. Their small footprint supports high-density installations, ensuring quick actuation and dependable performance in modern automation lines.

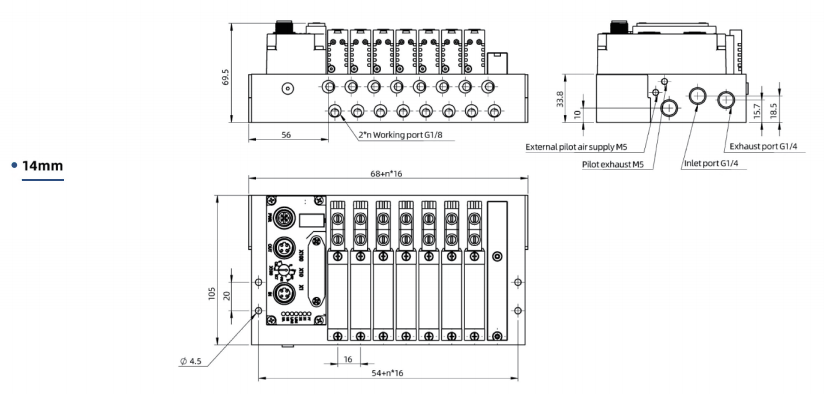

NTA valve terminals utilize 14mm solenoid valves to provide enhanced airflow and consistent actuation. Designed for applications with greater pneumatic demand, they support reliable control, long service life, and efficient performance across advanced automation systems.

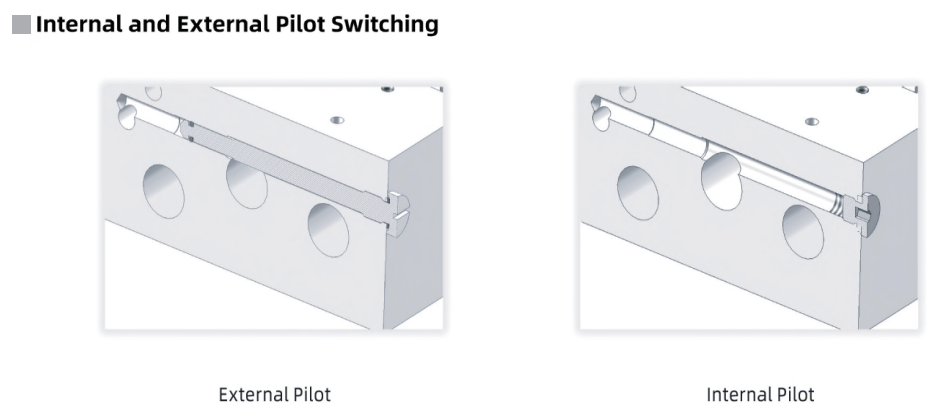

By fitting a screw into the pilot switching port, the valve can be configured for external pilot operation, with pilot air supplied through the M5 threaded port on the bottom plate. When an M5 plug is used instead, the unit functions as an internal pilot, drawing pilot air directly from the main inlet.

NTA valve terminals equipped with IO-Link modules provide seamless data access for monitoring and parameter adjustment. Using standard cabling, they streamline installation, enable predictive maintenance, and enhance reliability in intelligent automation systems.

Boosting Productivity with NTA Valve Terminals

By centralizing pneumatic control, NTA’s valve terminals significantly reduce the complexity of wiring, piping, and maintenance. This streamlined design improves system reliability, shortens commissioning time, and lowers the total cost of ownership. Their smart connectivity through IO-Link and Fieldbus allows real-time diagnostics, reducing downtime and increasing production efficiency.

If you are looking for a modular pneumatic valve terminal supplier, NTA provides reliable and customizable solutions tailored to your automation needs.

Why Choose NTA as Your Valve Terminal Supplier

Engineering Precision – Manufactured with tight tolerances under ISO-certified processes.

Customizable Configurations – Adaptable to different port sizes, electrical interfaces, and mounting needs.

Stable Quality Assurance – Every unit undergoes leakage, flow, and functional testing before delivery.

Global Support – Export-ready with multilingual technical assistance and efficient logistics.

For companies searching for valve terminal for automation systems or a trusted industrial valve terminal manufacturer, NTA ensures dependable performance backed by international standards.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.