In high-performance automation environments, space-efficient and dual-directional actuators are vital for precision and productivity. NTA's Synchronized Opposing-Motion Rodless Cylinder stands out as a cutting-edge pneumatic component, designed to deliver mirror-image motion within a single cylinder. As a trusted Chinese manufacturer, NTA provides customized, robust, and export-ready rodless cylinder solutions for global industrial systems.

×

Synchronized Opposing-Motion Rodless Cylinder Manufacturer from China — NTA

2025-04-18

Distinctive Advantages of NTA's Synchronized Rodless Cylinder

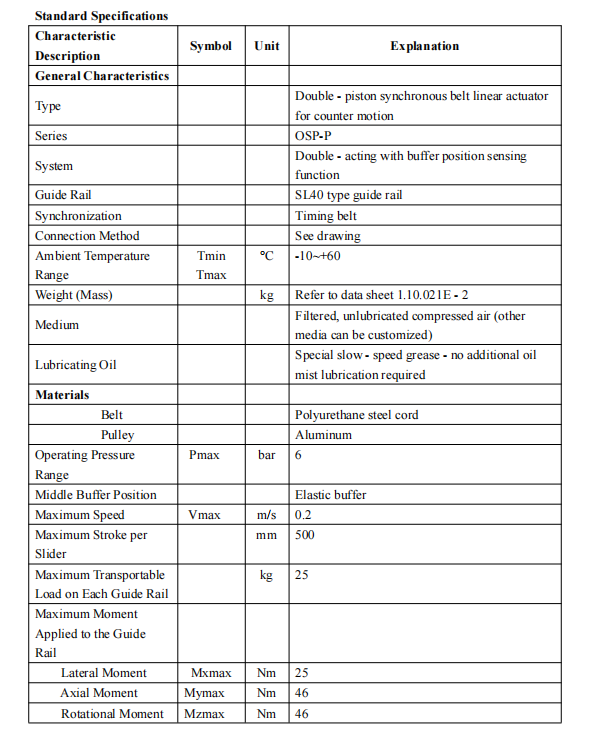

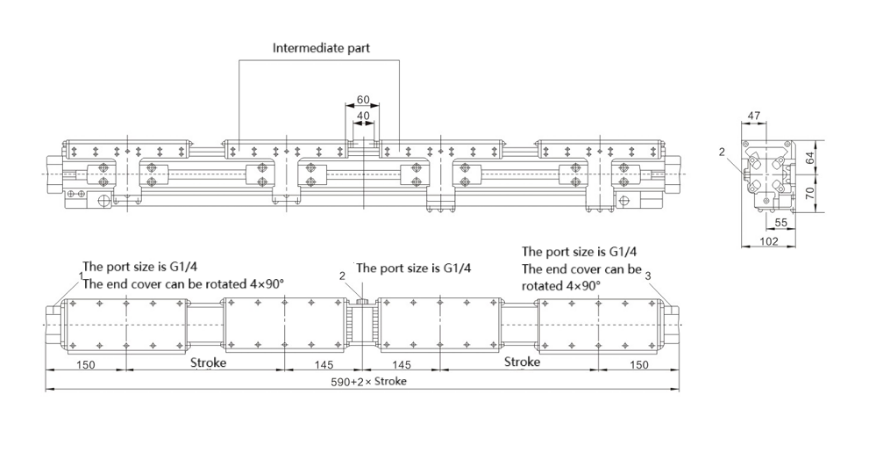

1. Opposing Dual-Piston Design: A pair of pistons operate in opposite directions simultaneously, ensuring symmetric and synchronized motion using a mechanical linkage or timing belt system.

2. Space-Efficient Form Factor: The rodless configuration eliminates protruding shafts, optimizing installations in tight spaces.

3. Balanced Load Distribution: Dynamic loads are managed effectively on both motion ends, reducing system strain.

4. Consistent Motion Accuracy: Delivers steady speed and pinpoint positioning ideal for repeat operations.

5. Built-in End Cushioning: Both end and central dampening improve mechanical safety and operational smoothness.

6. Sensor-Ready Configuration: Compatible with magnetic proximity sensors for real-time position monitoring.

As a double carriage synchronized rodless cylinder supplier, NTA also offers configurations that enable independent or synchronized motion on both sides of the cylinder, suitable for more complex mechanical coordination tasks.

Industries and Applications

Our opposing-motion cylinders are engineered for tasks requiring equal bidirectional force and alignment. Key applications include:

·

Automated Packaging Systems: For synchronized pushing/pulling of products with high repeatability. We offer custom synchronized rodless cylinders for packaging line upgrades tailored to unique machinery requirements.

·

Gripping and Clamping Mechanisms: Enabling precise parallel gripping actions in pick-and-place or handling units.

·

Dual-Side Access Modules: Such as automated doors, lids, or flaps that need to open evenly from both ends

·

Inspection Platforms: For central alignment in quality control and dimensional inspection systems.

·

Modular Conveyor Transfers: Where dual pushing from opposite ends is required for item positioning.

·

These use cases show how synchronized rodless cylinders for industrial automation projects can drastically improve coordination and reduce component redundancy.

Boosting Operational Efficiency

The integration of synchronized opposing pistons within a single housing reduces the need for separate actuators, brackets, and synchronization controls. This minimizes assembly time, increases design flexibility, and optimizes space utilization. The balanced motion mechanism lowers vibration, enhances durability, and promotes consistent throughput in high-speed production lines.

Why Partner with NTA?

Engineering Precision: All cylinders are produced with tight machining tolerances and ISO-grade materials.

·

Made-to-Order Flexibility: NTA supports full customization, including stroke length, interface ports, sensor slots, and mounting options.

·

Reliability in Operation: Field-proven in applications ranging from cleanroom automation to rugged industrial handling.

·

Full Lifecycle Support: Pre-sales consultation, post-sales technical service, and fast-response problem solving.

·

Global Trade Experience: With multilingual sales support and optimized logistics for international delivery.

Reliable and Stable Quality Control

NTA's production follows a verified quality assurance protocol from sourcing to final assembly. Each cylinder is subjected to pressure testing, dimensional inspection, and functional validation. Our consistent manufacturing process ensures dependable performance across long production cycles, even under demanding conditions.

Choose NTA's Synchronized Opposing-Motion Rodless Cylinders for your automation upgrades and benefit from streamlined mechanics, precision control, and global-class service. Contact our team to explore tailored pneumatic solutions for your workflow.

ReviewsNumber of comments: {{ page.total }}

I want to comment?

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

Reviews

Merchant

{{replyItem.nickname ? (replyItem.nickname.slice(0, 2) + '*****') : replyItem.source === 1 ? 'mall buyer' : '--'}}

{{replyItem.parent_nickname ? (replyItem.parent_nickname.slice(0, 2) + '*****') : '--'}}

{{replyItem.is_merchant_reply === 1 ? replyItem.reply_time : replyItem.comment_time}}

Review in the {{replyItem.country}}

Reviews

No customer reviews

If you have more questions, write to us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Recommended

QUICK LINKS

Products

Please contact us

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.