Titan Automation- leading pneumatic cylinders manufacturer & supplier specializing in pneumatic air cylinders for industrial automation needs.

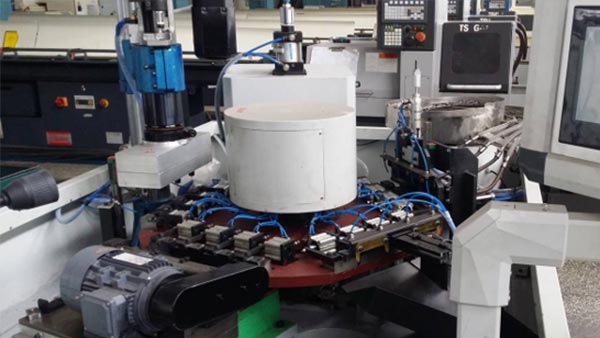

We Own 26 Sets Of N.t.a(titan) Self Developed Automatic Lathe

Production time by regular lathe: 135 s/pc

Production time by automatic lathe: 22 s/pc

Production capacity by regular lathe:800pcs/8hrs

Production capacity by automatic lathe: 2600pcs/8hrs

Production time by regular lathe: 193 s/pc

Production time by automatic lathe: 43 s/pc

Production time by hand: 36 s/pc

Production time by automatic lathe: 12 s/pc

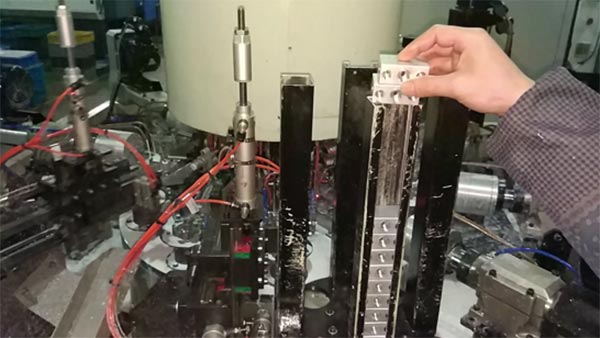

N.T.A(TITAN) self developed valve body drilling automatic lathe

We own 10 sets of LK die casting machine

● Stable and high performance injection system

● Injection powered by piston type accumulator, providing high injection speed

● Advanced control ensures high productivity

● Energy saving,high efficiency

● High reliability

Used to die cast valve body, pneumatic cylinder front cap, rear cap, pneumatic cylinder piston and some mounting spare parts

We own 1 die casting parts infiltration line

The infiltration treatment is to immerse the die-casting part in the impregnating liquid for impregnation and filling, so that the impregnating liquid penetrates the loose parts inside the die-casting part, thereby improving the air-tightness of the die-casting part.

We own 1 industrial tunnel oven

Tunnel oven is preferred for mass production of our directional valves, filter regulator lubricators, pneumatic cylinder parts and other machined parts in different sizes

We own 6 manual painting lines

We own 6 spray paint oven

We own 1 robot spraying production line

The position of the robot is much more precise and repeatable than with a human painter. Speed (as much as 30 times faster than manual methods) keeping our workers safe from harmful fumes and chemicals. Reduced cost by minimizing the amount of wasted coating.

We own 9 pneumatic tube manufacturing automatic lines

Output 200 tons of PU tubes, PTFE tubes, PE tubes, PA tubes, PVC reinforced tubes each month

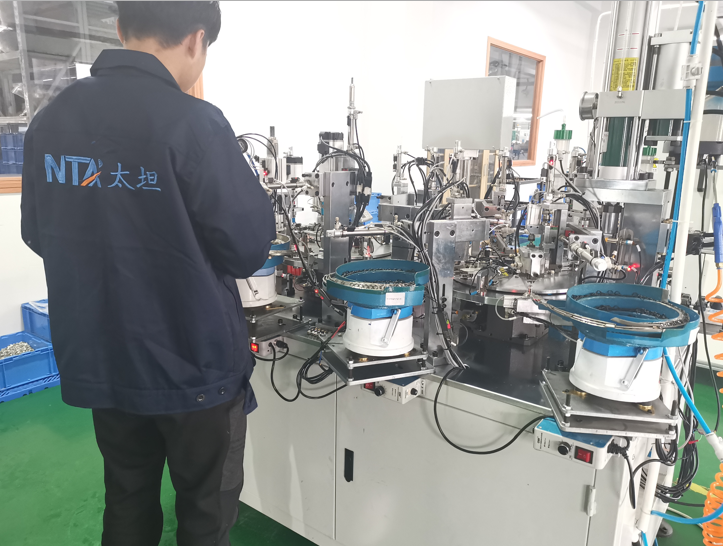

We own pneumatic push in fitting automatic assembly system

By using the automatic assembly system, fitting production efficiency increased by 50% !

Die Spotting Pressing Machine

Mold processing equipment

We own hundreds of aluminium parts die casting molds, most of them are developed by ourown.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.