Compact Valve Terminals for Industrial Automation — NTA

NTA offers high-quality pneumatic valve terminal designed for demanding industrial applications. Known for their compact design and versatility, our terminals for industrial automation can integrate 4 to 24 valves in a single module, optimizing space utilization in space-constrained installation environments. As a leading Chinese manufacturer, NTA offers high-performance valve terminal systems that can be customized to the precise needs of your automation project.

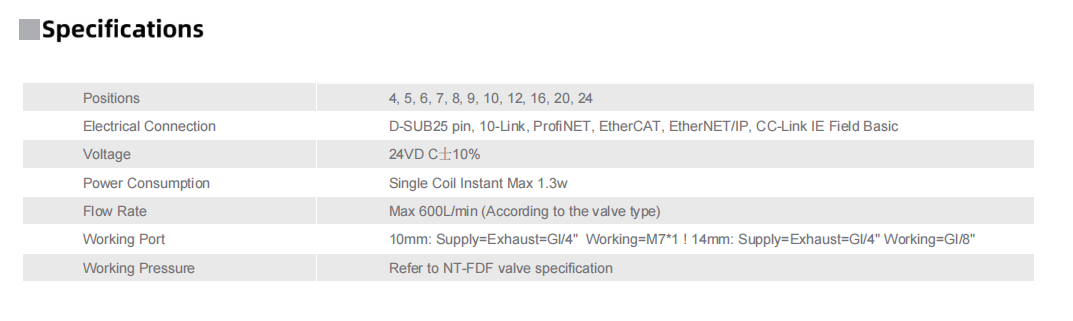

Technical features of valve terminals:

1. The valve terminals we offer have the following unique features:

2. Modular design, customizable configuration for specific needs

3. Compatible with control voltages from 12V DC to 230V AC

4. High flow rates with minimal energy consumption

5. Can accommodate up to 24 valve positions

6. Can be manually actuated by pushbutton or switch

7. Flow rates up to 600L/Min

Valve Terminals

Valve terminals are essential components in industrial automation systems that require precise fluid control. These devices act as an interface between electrical control systems and pneumatic components and are able to efficiently manage multiple valves in a compact space.

Valves are pneumatic components used in automation technology to control actuators such as cylinders, rodless cylinders, motors or grippers. As for the valves themselves, Festo offers a wide range of different designs and models, divided into pneumatic valves, electric valves and manual valves. In addition, we also provide valves for use in conjunction with valve terminals, depending on system requirements.

The construction quality of our valve terminals guarantees durability and performance in industrial environments:

Valve body: high-strength aluminum

Coil structure: aluminum

Seals: NBR rubber, excellent sealing

Springs: corrosion-resistant stainless steel

Housing: technical plastic (PA, PC)

Mounting system: SCP1

Key Features of NTA Valve Terminals

Space-Saving Modular Design

NTA valve terminals combine multiple solenoid valves in one compact system, optimizing space and simplifying integration in tight areas of control panels or machinery.

Customizable Configurations

Tailored solutions to meet various application needs, including different valve types, port sizes, and manifold layouts to accommodate specific flow and performance requirements.

Efficient Installation & Maintenance

Designed with easy-to-use plug-in connectors and modular components, NTA valve terminals simplify installation and maintenance while minimizing downtime.

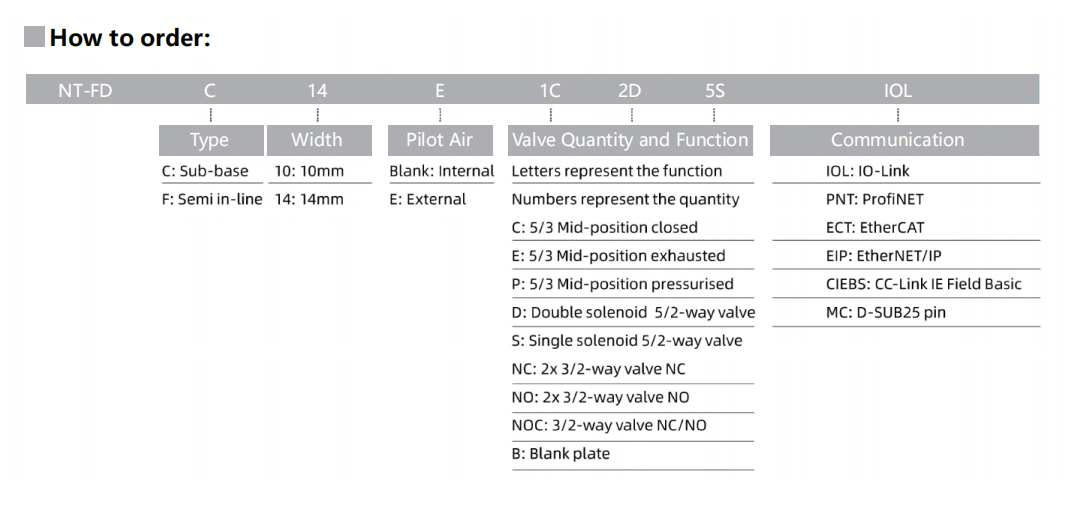

Seamless Communication Integration

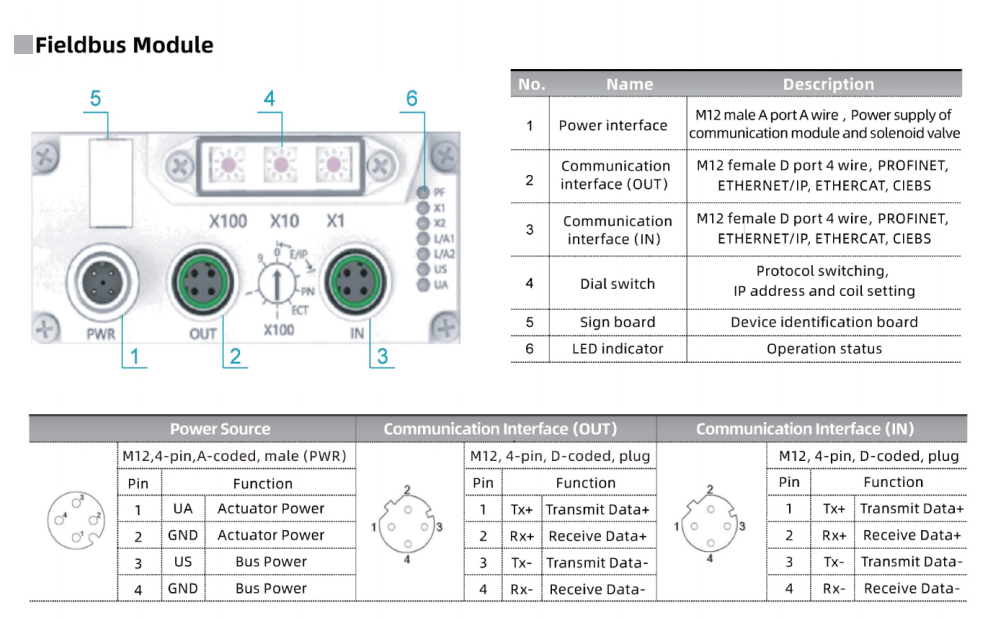

Our systems support industry-standard communication protocols, such as EtherCAT, Modbus, and PROFINET, ensuring smooth connectivity with PLCs and other control systems.

Rugged, Industrial-Grade Performance

NTA valve terminals are built for durability with corrosion-resistant materials and high IP-rated protection, making them ideal for harsh environments.

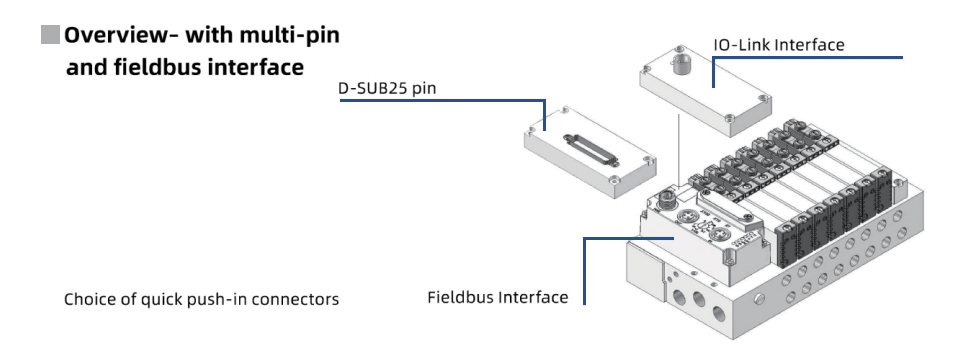

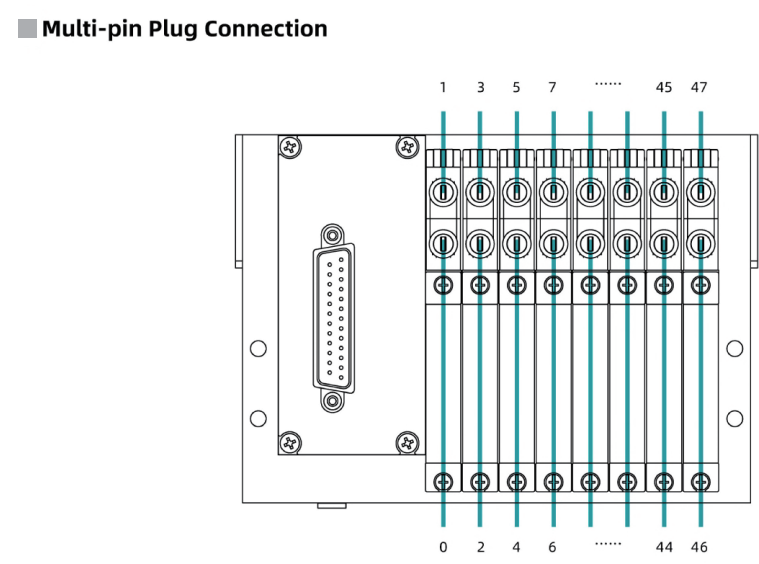

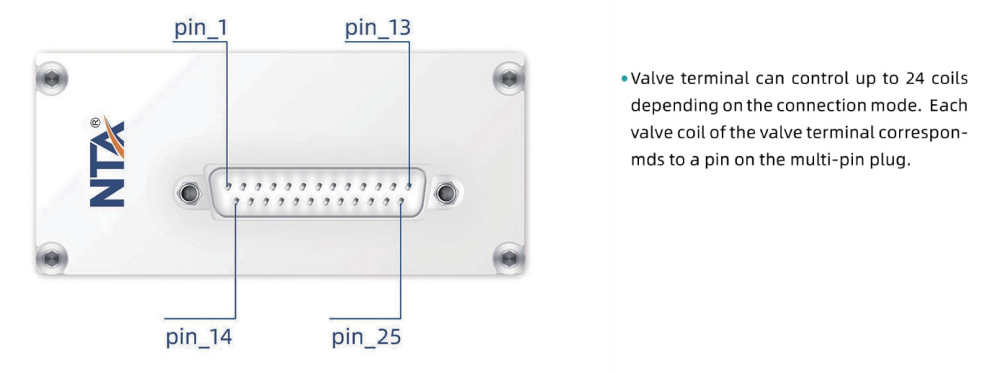

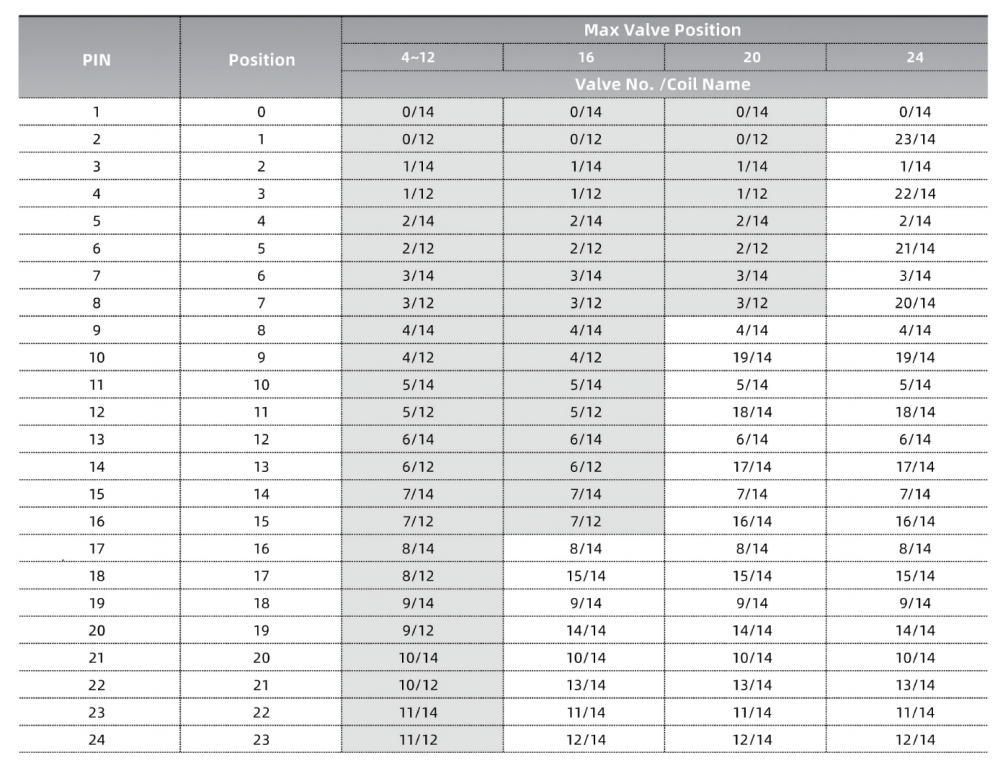

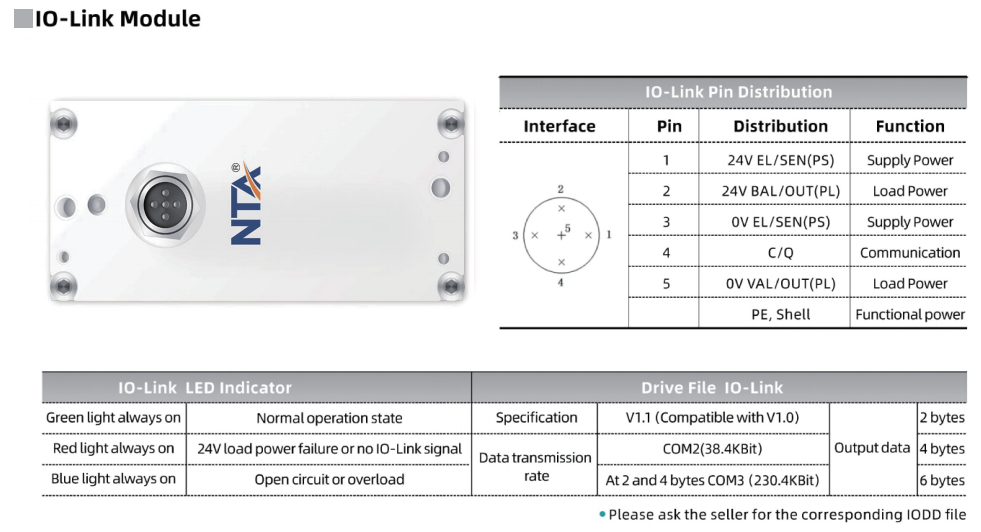

NTA Valve Terminals support D-SUB 25-pin, IO-Link, and Fieldbus interfaces, allowing fast installation, smart diagnostics, and seamless integration with various control systems.

This flexible connectivity boosts automation efficiency and simplifies system upgrades.

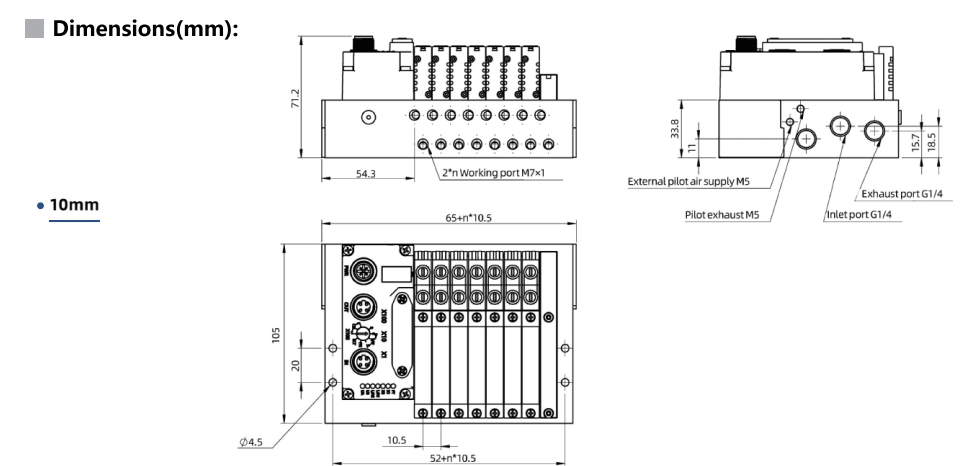

NTA valve terminals are equipped with compact 10mm solenoid valves, offering high flow performance in a space-saving design. Ideal for dense installations,

they reduce footprint while maintaining fast response and reliable operation in demanding automation environments.

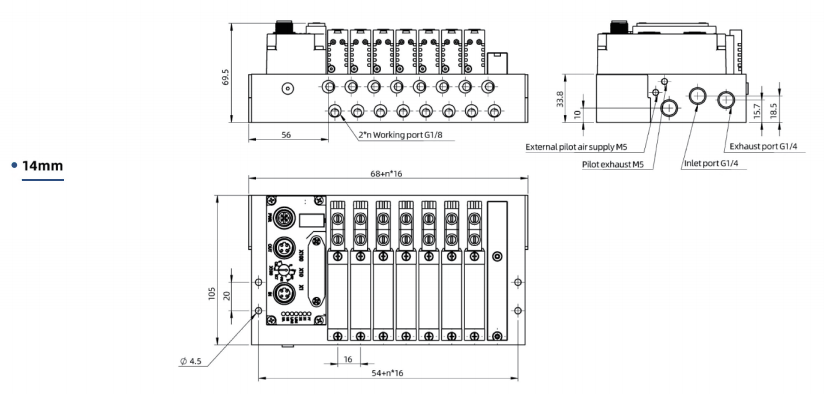

NTA valve terminals feature robust 14mm solenoid valves, delivering higher flow capacity and reliable switching performance.

Suitable for medium to high-demand applications, they ensure stable operation and efficient air control in automated systems.

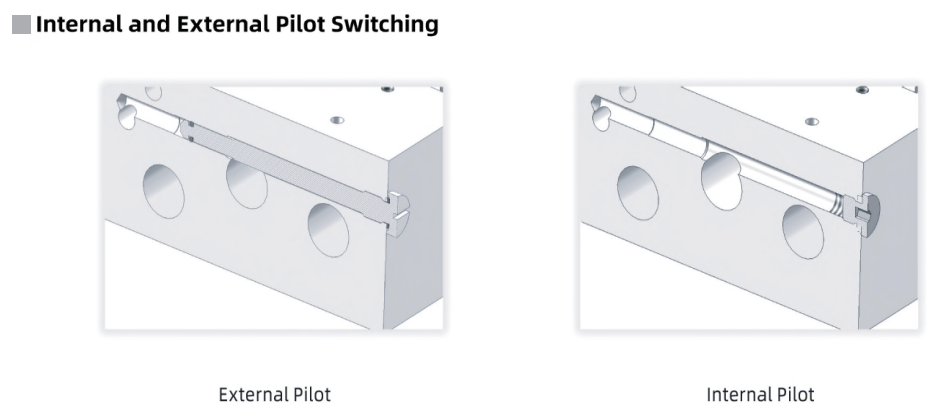

Installing screw at the pilot switching hole can realize the external pilot function, pilot air through the M5 threadedhole at the end face of the bottom plate.

lnstalling M5 plug at the pilot switching hole can realize the internal pilot function, pilot air directly though the aiinlet of the bottom plate.

NTA valve terminals with IO-Link modules enable real-time monitoring, remote configuration, and advanced diagnostics.

They simplify wiring with standard cables and support predictive maintenance, improving system flexibility and reducing downtime in smart automation environments.

Applications Across Various Industries

NTA valve terminals are ideal for a wide range of industrial applications, including:

Automated Assembly and Production Lines

Control multiple pneumatic actuators with ease in highly automated environments.

Packaging Systems

Coordinate air control for tasks such as sealing, labeling, and product handling.

Material Handling and Sorting

Manage air-driven systems in conveyor lines, gates, and pushers to ensure smooth product flow.

Process Automation

Precisely control airflow in food production, chemical processing, and other automated processes.

Tailored Solutions for OEMs

We work closely with OEMs to provide integrated valve terminals suited to custom automation needs.

Why Choose NTA Valve Terminals

Robust Quality Control

Every NTA valve terminal is manufactured under ISO-certified procedures, ensuring rigorous performance testing, leak detection, and quality assurance before shipping.

Tailored Solutions for Specific Needs

NTA offers customization for various operational needs, from valve configuration to manifold design and communication interfaces.

Global Reach and Expertise

With a strong presence in markets across Europe, North America, and Southeast Asia, NTA is a trusted supplier for industrial automation systems worldwide.

End-to-End Support

NTA provides comprehensive pre-sales consultations, timely production, and responsive after-sales support to meet every project requirement.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.