Advanced Valve Terminals for Reliable Pneumatic Automation | NTA

NTA valve terminals deliver the reliability, flexibility, and efficiency demanded by modern industrial automation. With compact layouts, robust construction, and versatile communication interfaces, they help manufacturers achieve higher productivity and lower downtime. From packaging to automotive, logistics to electronics, NTA valve terminals empower businesses to optimize their operations and build the future of intelligent pneumatic control.

Product Features

NTA valve terminals provide efficient pneumatic control with a focus on performance and adaptability:

Modular layout for flexible system configuration

Optimized airflow valves for stable and responsive operation

Multiple interface options for easy connectivity in smart systems

Robust build to ensure reliability in continuous operation

Monitoring-enabled design for proactive maintenance

Key Features of NTA Valve Terminals

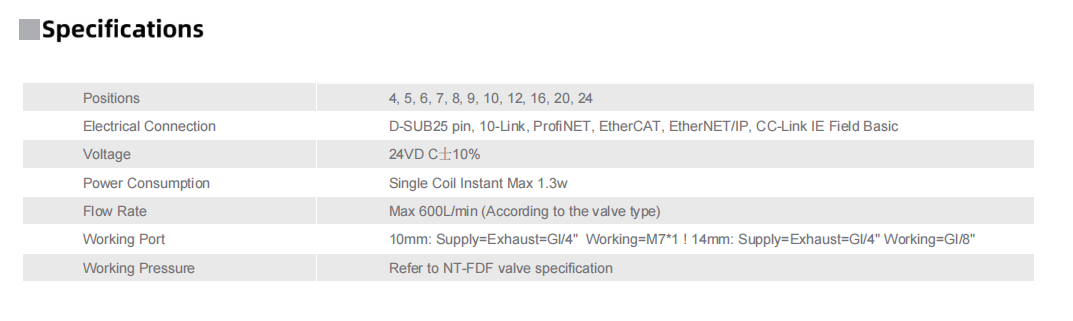

NTA valve terminals are built with high-performance engineering to meet diverse industrial requirements:

Compact design saves installation space without compromising airflow

Modular configuration tailored for scalable automation projects

Multiple communication interface options for seamless system integration

Durable construction ensures consistent operation under demanding conditions

Integrated monitoring supports predictive maintenance and system optimization

These benefits make NTA a trusted supplier of precision pneumatic valve distribution systems designed for industries worldwide.

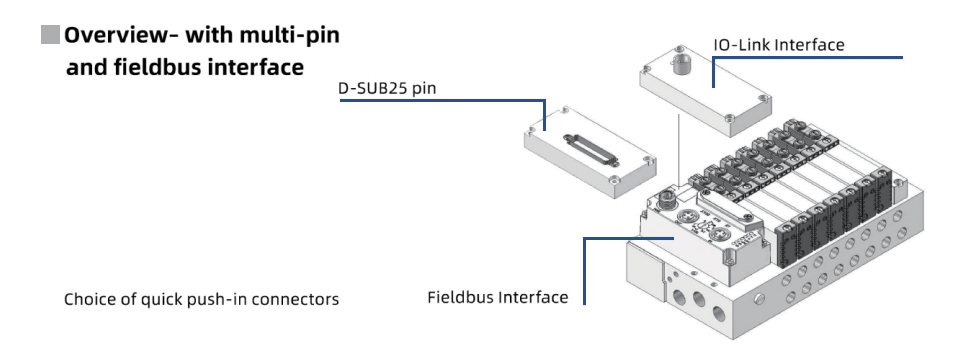

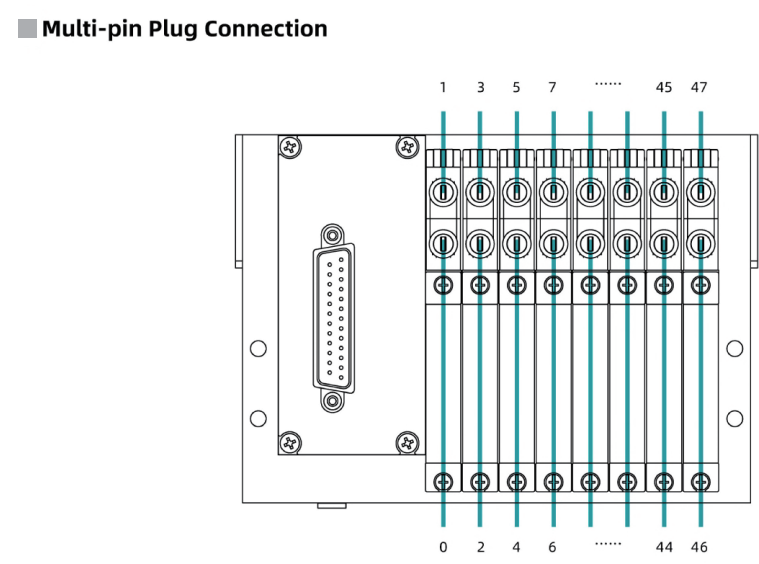

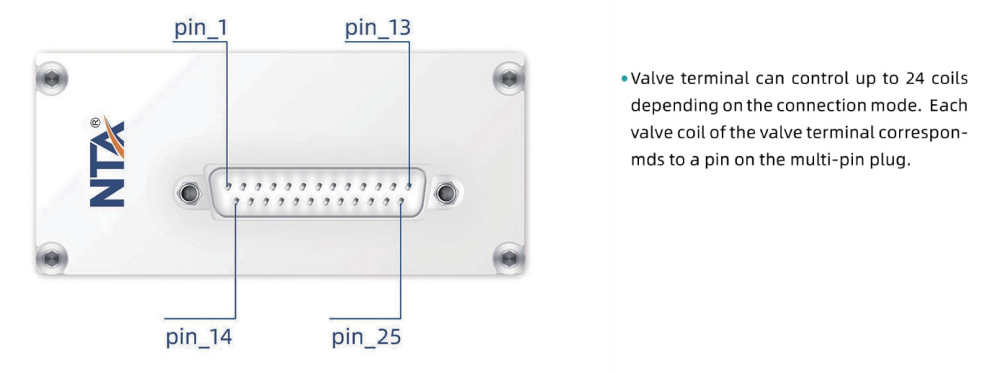

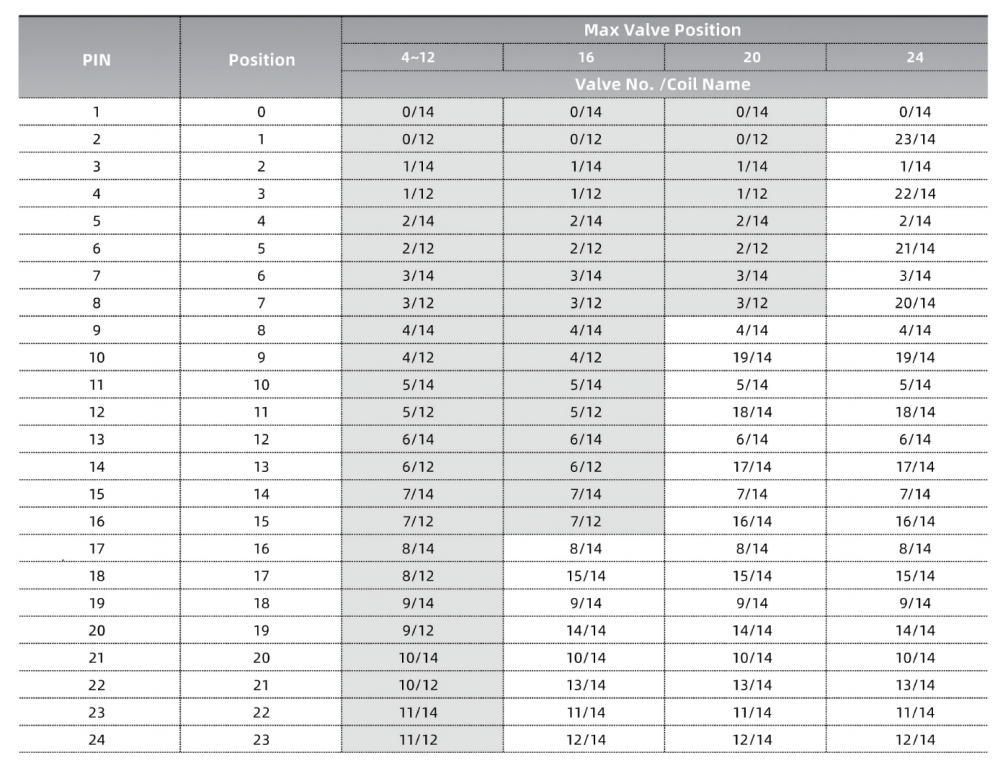

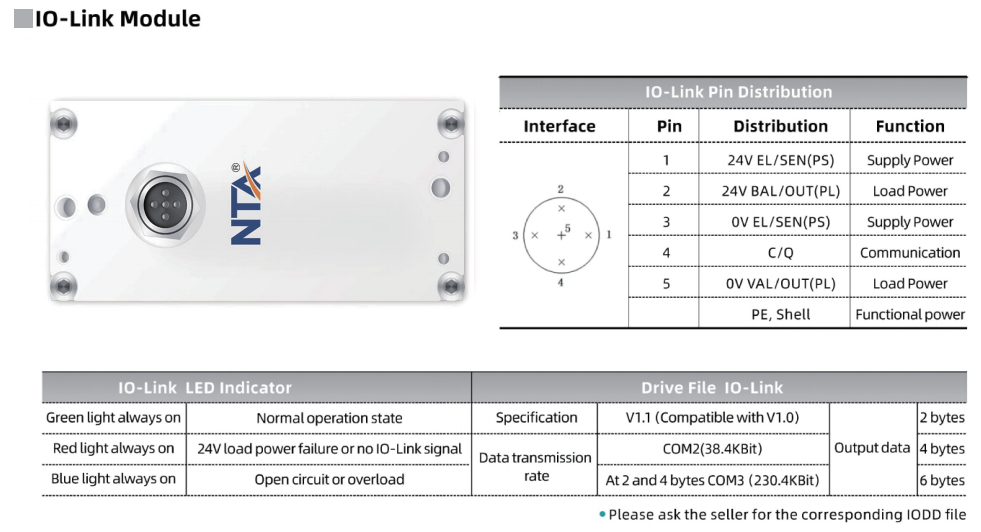

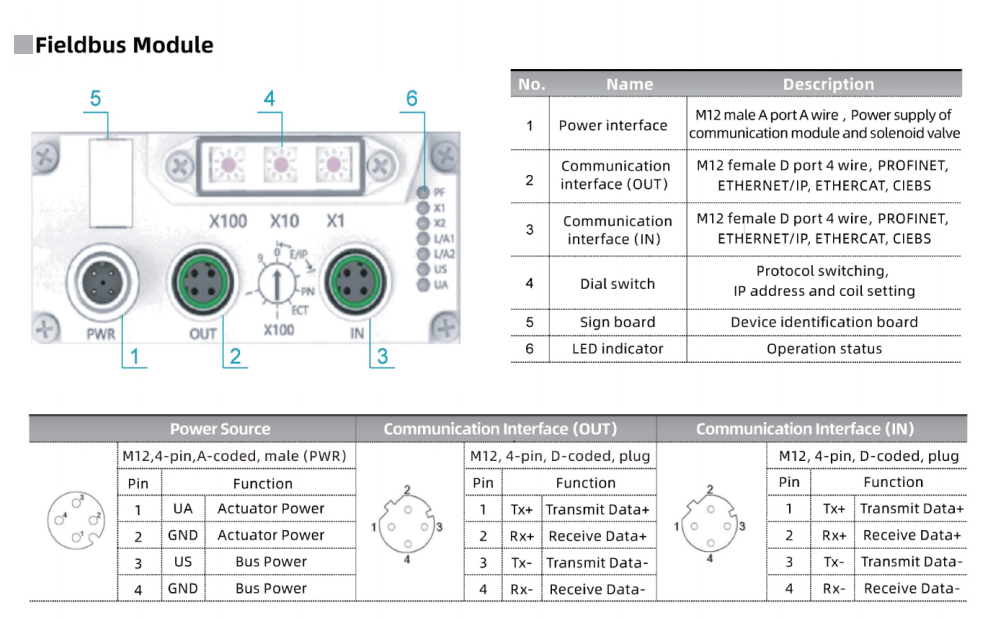

NTA valve terminals support 25-pin, IO-Link, and Fieldbus connectivity, ensuring effortless integration, reliable data exchange, and enhanced efficiency across automated processes.

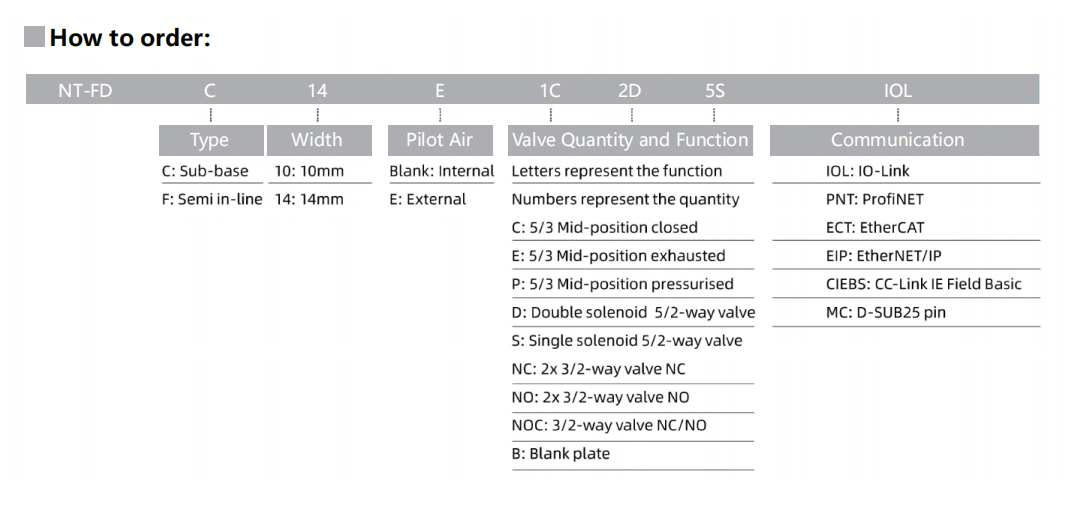

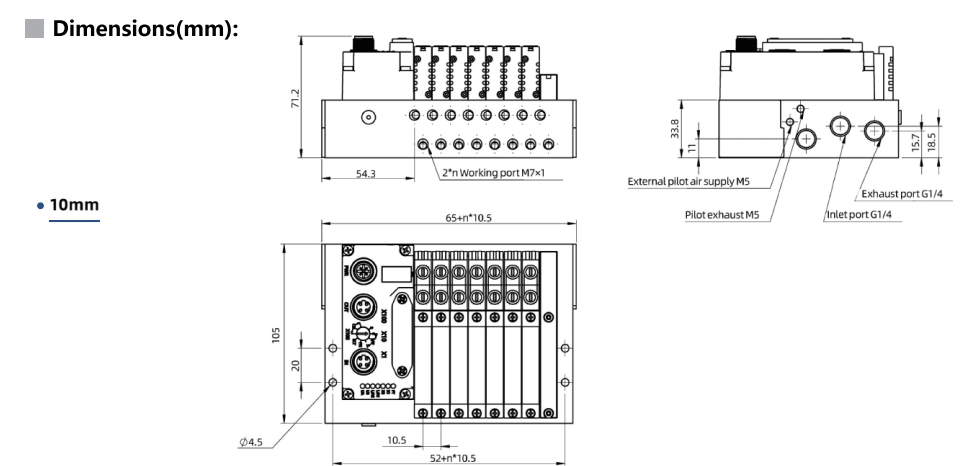

NTA valve terminals feature 10 mm solenoid valves arranged in a space-saving configuration, providing high flow output while minimizing installation requirements. The streamlined design ensures quick response times and reliable functionality in demanding automation applications.

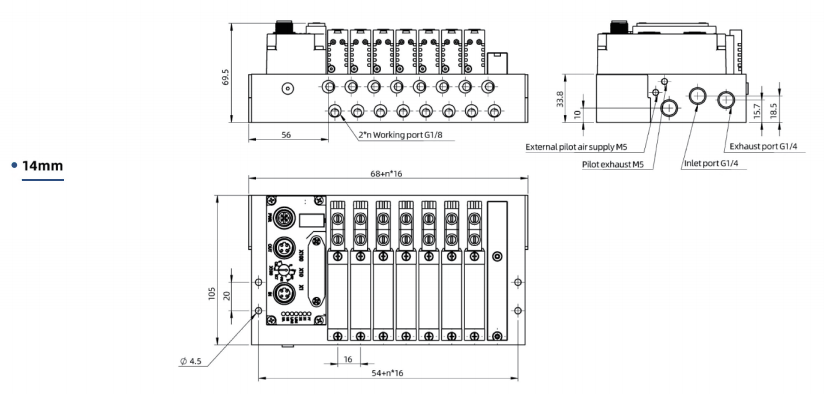

NTA valve terminals incorporate 14 mm solenoid valves designed to deliver higher flow output and reliable switching performance. Built for demanding industrial automation, they ensure precise control, extended durability, and efficient operation across sophisticated production lines.

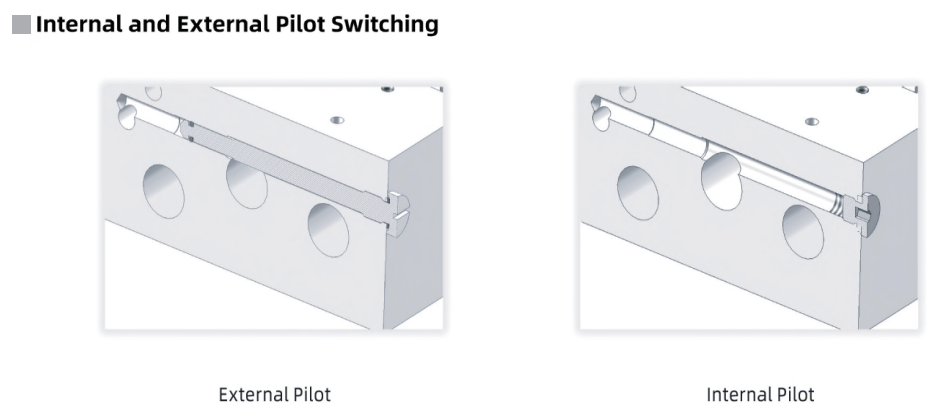

Inserting a screw into the pilot port configures the valve for external pilot operation, supplying pilot air via the M5 threaded port on the base plate. Installing an M5 plug changes the setup to internal pilot mode, where pilot air is sourced directly from the primary inlet.

NTA valve terminals with integrated IO-Link modules provide real-time diagnostic capabilities and easy parameter setup. With standard cabling, they simplify system installation, support predictive maintenance strategies, and ensure stable performance in smart automation environments.

Application Scenarios

NTA valve terminals are widely used across industries where productivity and reliability are critical:

Packaging machinery – ensuring smooth and accurate motion control

Automotive production – enhancing robotic welding, assembly, and painting processes

Electronics manufacturing – enabling precise control in compact layouts

Logistics and warehousing – improving conveyor efficiency and automated handling

Their adaptability establishes NTA as a leader in delivering intelligent modular pneumatic valve blocks that help manufacturers achieve leaner and smarter operations.

Enhancing Efficiency and Reliability

Efficiency and reliability are essential in industrial automation, and NTA valve terminals are engineered to deliver both. Fast actuation, dependable performance, and modular expandability allow manufacturers to keep up with production demands.

Simplified installation with flexible connectivity options reduces setup time and lowers maintenance requirements. With built-in diagnostic capabilities, NTA products act as a smart pneumatic valve terminal control platform, reducing downtime while improving productivity in modern factories.

Advantages of Choosing NTA

At NTA, every valve terminal is produced under strict quality management, ensuring international compliance and long-term dependability. Key advantages include:

Reliable performance even under heavy workloads

Easy system expansion to match future growth

Energy efficiency, reducing operating costs

Broad compatibility with global automation standards

By combining quality with innovation, NTA provides automation-optimized pneumatic valve terminal solutions that ensure stable operation and long service life.

Supporting Smart Factories

The evolution toward Industry 4.0 requires pneumatic solutions that merge digital intelligence with mechanical reliability. NTA valve terminals meet this need with modern connectivity, real-time diagnostics, and scalable control. Their advanced design makes them a cornerstone of field-proven pneumatic control valve islands, supporting the transition to smart and sustainable factories.

QUICK LINKS

We are confident to say that our customization service is outsatnding.

0086-136 1656 9784

0086-136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086 136 1656 9784

0086 136 1656 9784 0086-574-8702 2814

0086-574-8702 2814 www.titan-automation.com

www.titan-automation.com

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.

NO.188,Nanshan North Road,Ningbo City,Zhejiang Province, China.